Industrial waste water treatment device and production and application method thereof

A technology for industrial wastewater and treatment devices, applied in the direction of adsorption water/sewage treatment, combustion methods, lighting and heating equipment, etc., can solve problems such as efficiency reduction, biomass ashing, and cost increase of adsorbents, achieving high efficiency and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Step 1. Weigh about 13.96g of washed and dried ginkgo leaves, put them into a cylindrical compression cylinder, compress the compressor, and press the fallen leaves to 5×10 on the backing plate with a tablet press. 5 Pa.

[0034] Step 2. Take out the entire compression molding device. At this time, the inside of the device is approximately a vacuum. Heat the whole device to carbonize the ginkgo leaf cake. Stop heating after carbonization for one hour. After cooling, take out the ginkgo leaf block. After cooling, the mass of 4.96g, Ginkgo biloba cake-shaped adsorbent with a diameter of 45 mm and a degree of carbonization of γ=64.5%.

[0035] Step 3. Repeat steps 1-2 multiple times to obtain 3 ginkgo biloba cake-like adsorbents.

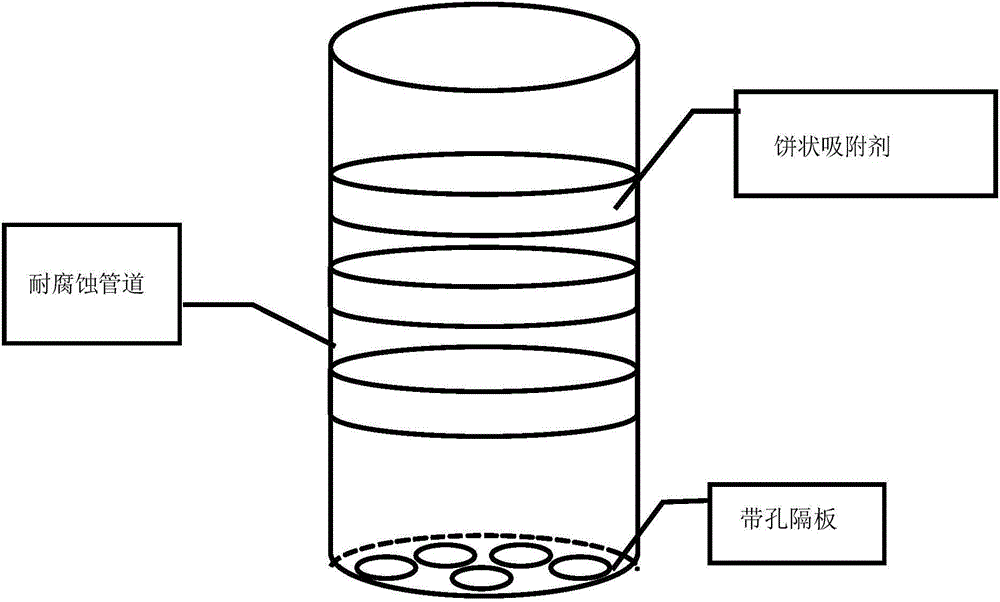

[0036] Step 4. After stacking three ginkgo leaf cake-shaped adsorbents into rubber tubes of the same diameter, reinforce them with plastic tubes to form a columnar adsorption filter device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com