Hydration and anhydrous multistage porous calcium borate microsphere low-temperature hydrothermal-thermal conversion synthetic method

A synthetic method, calcium borate technology, applied in the direction of boron oxides, borates, etc., to achieve the effect of pure composition, cheap and easy-to-obtain raw materials, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

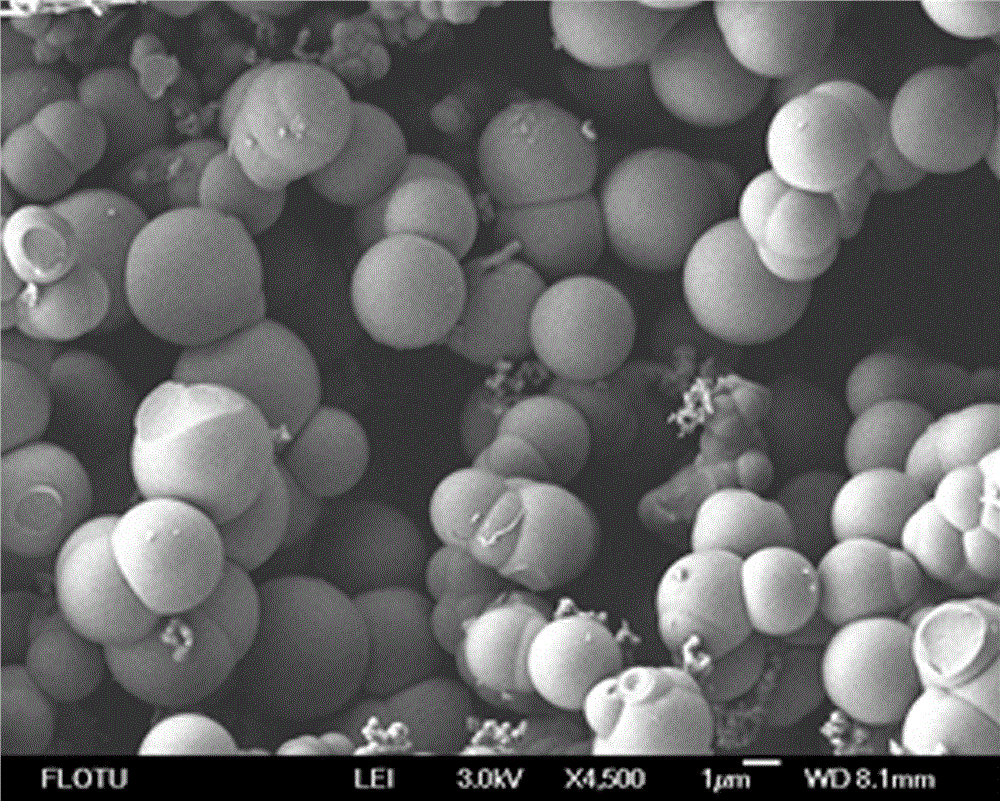

Embodiment 1

[0033] A low-temperature hydrothermal-thermal conversion synthesis method of hydrated and anhydrous multi-level porous calcium borate microspheres, comprising the following steps: (1) adding 10 ml of ammonia water to 10 ml of 0.5 mol / L calcium chloride solution, Mix evenly to obtain a mixed solution; (2) Add 0.005 mol of borax solid powder to the mixed solution, add 20 ml of water, and stir for 10 min to obtain a slurry; (3) Put the slurry in a hydrothermal reaction kettle, Heat up to 120 oC, react at constant temperature for 9.0 h, then cool down to room temperature naturally to obtain the hydrothermal product; (4) wash and filter the hydrothermal product in sequence, and dry at 70 oC for 12.0 h to obtain Ca 4 B 10 o 19 ?7H 2 O microspheres; (5) Ca 4 B 10 o 19 ?7H 2 O microspheres were placed in a calcination furnace, and the temperature was raised to 650 oC at a rate of 5 oC / min. After calcination for 12.0 h, the crude product was naturally cooled to room temperature t...

Embodiment 2

[0036] A low-temperature hydrothermal-thermal conversion synthesis method of hydrated and anhydrous multi-level porous calcium borate microspheres, comprising the following steps: (1) adding 2 ml of ethylenediamine to 10 ml of 0.8 mol / L calcium chloride solution , mixed evenly to obtain a mixed solution; (2) Add 0.005 mol of borax solid powder to the mixed solution, add 20 ml of water, and stir for 10 min to obtain a slurry; (3) Put the slurry in a hydrothermal reaction kettle Inside, heat up to 100 oC, react at constant temperature for 12.0 h, then naturally cool to room temperature to obtain the hydrothermal product; (4) The hydrothermal product was washed, filtered, and dried at 70 oC for 12.0 h to obtain Ca 4 B 10 o 19 ?7H 2 O microspheres; (5) Ca 4 B 10 o 19 ?7H 2 O microspheres were placed in a calcination furnace, and the temperature was raised to 750 oC at a rate of 5 oC / min. After calcination for 2.0 h, the crude product was naturally cooled to room temperature ...

Embodiment 3

[0040] A low-temperature hydrothermal-thermal conversion synthesis method of hydrated and anhydrous multi-level porous calcium borate microspheres, comprising the following steps: (1) adding 10 ml of 0.4 mol / L hydroxylamine hydrochloride solution to 10 ml of 0.8 mol / L Calcium chloride solution, mixed evenly to obtain a mixed solution; (2) Add 0.016mol boric acid solid powder to the mixed solution, add 10 ml of water, and stir for 10 min to obtain a slurry; (3) Put the slurry in In a hydrothermal reaction kettle, heat up to 150 oC, react at constant temperature for 6.0 h, then cool to room temperature to obtain a hydrothermal product; (4) wash and filter the hydrothermal product in sequence, and dry at 70 oC for 12.0 h to obtain Ca 4 B 10 o 19 ?7H 2 O microspheres; (5) Ca 4 B 10 o 19 ?7H 2 O microspheres were placed in a calcination furnace, and the temperature was raised to 650 oC at a rate of 10 oC / min. After calcination for 2.0 h, the crude product was naturally cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com