Boring method of toughened plastic part

A toughened plastic and boring technology, which is applied in metal processing and other directions, can solve the problems that affect the processing quality and are not suitable for processing toughened plastic parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

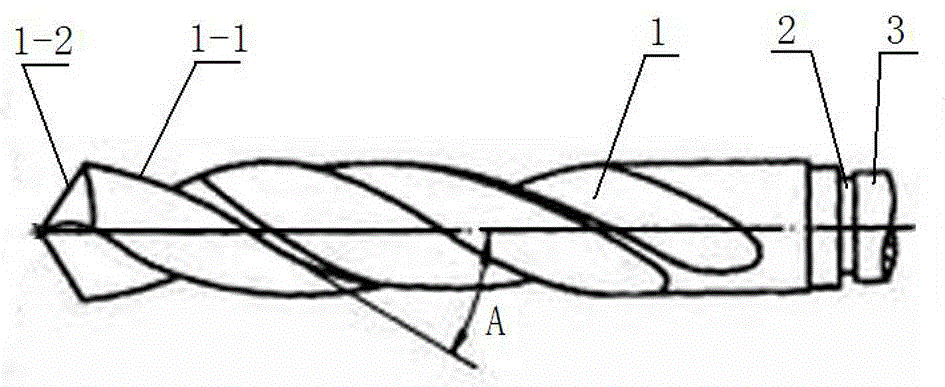

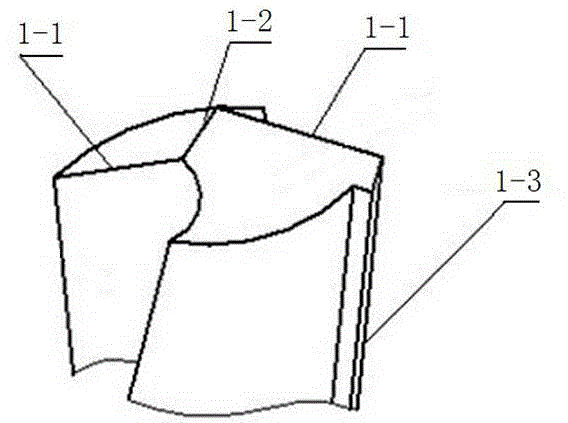

[0017] The method for boring a toughened plastic part includes processing a toughened plastic part with a toughened plastic part boring drill. Toughened plastic parts boring drill such as figure 1 , figure 2 As shown, it includes a cutting part 1 and a shank 3, and there is a neck 2 between the cutting part 1 and the shank 3. The cutting part 1 includes two main cutting edges 1-1 arranged symmetrically with the center line, and one main cutting edge One side of the 1-1 is provided with an edge 1-2, two main cutting edges are provided with grooves in front, the main cutting edge 1-1 and the edge 1-2 are axially twisted, and the end of the cutting part 1 is provided with The chisel edges 1-3 on both sides are arranged symmetrically with the center line, the material of the cutting part is cemented carbide, and the whole cutting part is made of stronger cemented carbide material or diamond material, so that the drill can meet the requirements of strength without being affected ...

Embodiment 2

[0024] The method for boring a toughened plastic part includes processing a toughened plastic part with a toughened plastic part boring drill. The material of the cutting part of the toughened plastic part boring drill can also be selected from diamond, and the torsion angle can be 16°, and other structures are as in the first embodiment.

[0025] Its processing method comprises the following steps:

[0026] A: Preheating: Preheat the toughened plastic parts to be processed, the heating temperature is 130°C, and the cross-sectional area is 60 minutes per 10 square millimeters;

[0027] B: Pre-drilling: Pre-drill the toughened plastic parts to be processed with a hollow drill;

[0028] C: Drilling: use the toughened plastic part boring drill to shape the toughened plastic part to be processed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com