Light-emitting diode chip and preparation method thereof

A technology of light-emitting diodes and chips, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of waterproof and unsatisfactory heat dissipation performance of the protective layer, and achieve good waterproof effect, high thermal conductivity, and good thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

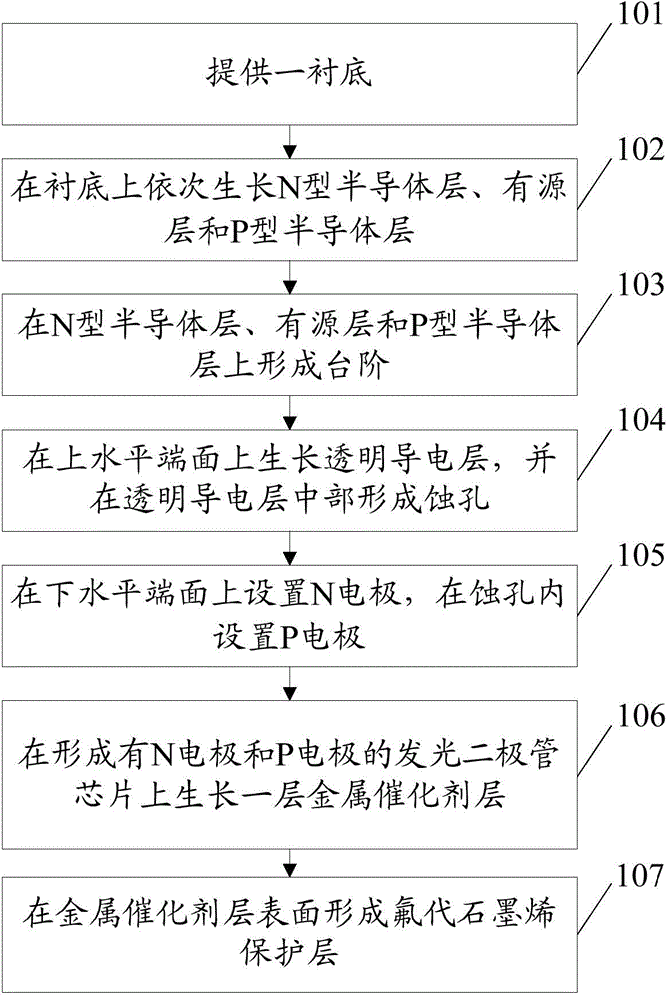

[0037] figure 1 A flow chart of a method for preparing a light-emitting diode chip is provided, see figure 1 , the preparation method of the light emitting diode chip comprises:

[0038] Step 101: Provide a substrate.

[0039] In this embodiment, the substrate includes but is not limited to a sapphire substrate or a silicon substrate.

[0040] Step 102: growing an N-type semiconductor layer, an active layer and a P-type semiconductor layer sequentially on the substrate.

[0041] In this embodiment, an N-type semiconductor layer, an active layer, and a P-type semiconductor layer may be sequentially grown on the substrate by using a Metal-organic Chemical Vapor Deposition (MOCVD) method.

[0042] Further, before step 102, at least one buffer layer may also be grown on the current substrate, so as to better grow subsequent structures.

[0043] Step 103: forming a step on the N-type semiconductor layer, the active layer and the P-type semiconductor layer, the step includes an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com