IGBT (Insulated Gate Bipolar Transistor) chip manufacturing method for crimped type package

A manufacturing method and crimping technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, transistors, etc., can solve problems such as high process precision requirements, high processing costs, and extended chip processing cycle, and achieve low process precision requirements , save the cost of tape-out, and ensure the effect of electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

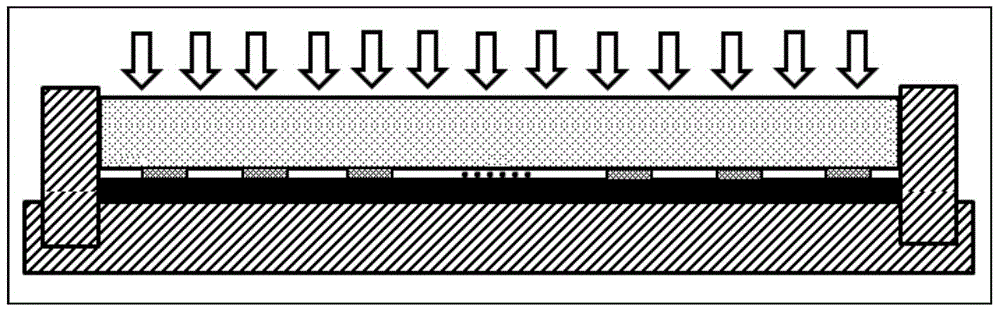

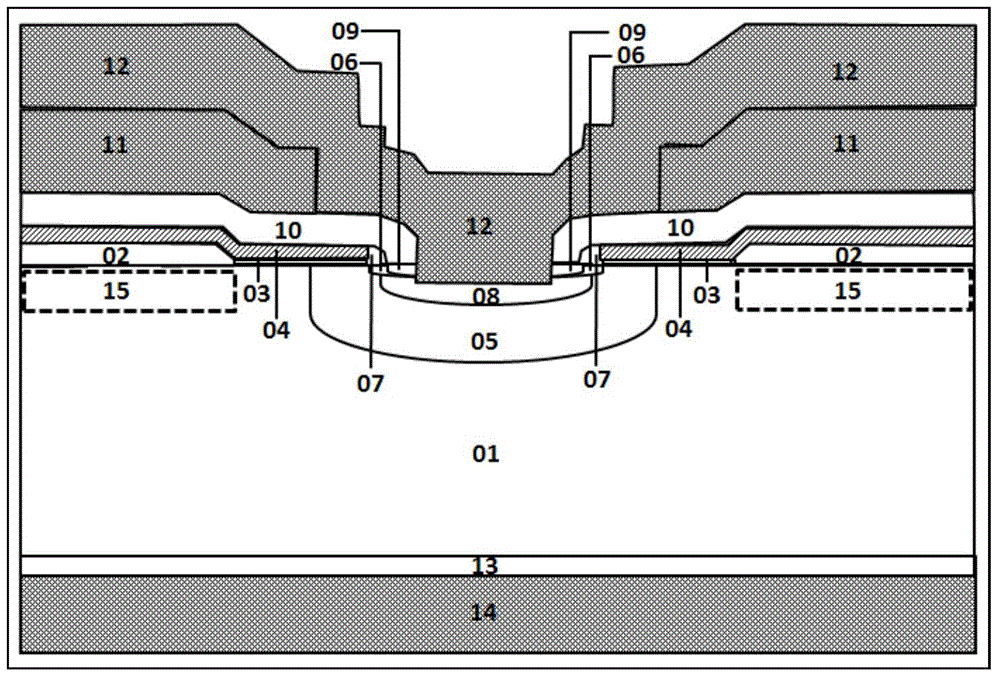

[0034] The invention of this example provides a method for manufacturing an IGBT chip suitable for press-fit packaging, including: figure 2 as shown,

[0035] (1) N-type single crystal silicon wafer substrate 1, the doping concentration of the substrate N impurity and the thickness of the substrate need to be selected according to different breakdown voltage and forward conduction voltage drop requirements (600V to 6500V). Alkali, deionized water ultrasonic cleaning and other processes are used to chemically treat the silicon surface.

[0036] (2) Field oxide layer 2 growth and etching: use high temperature oxidation to grow an oxide layer on the surface of the silicon wafer with a thickness of 1000-1500nm. After the growth is completed, perform photolithography and wet etching. The smoother the etching angle of the oxide layer The better, the final angle is about 30°, and the field oxygen is 10-12μm away from the polycrystalline opening.

[0037] (3) Fabrication of chip pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com