A kind of method for preparing nickel phosphide/graphene composite film material

A graphene composite and thin-film material technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of harsh reaction conditions and high reaction temperature, and achieve easy large-scale production and simple and easy-to-control experimental methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

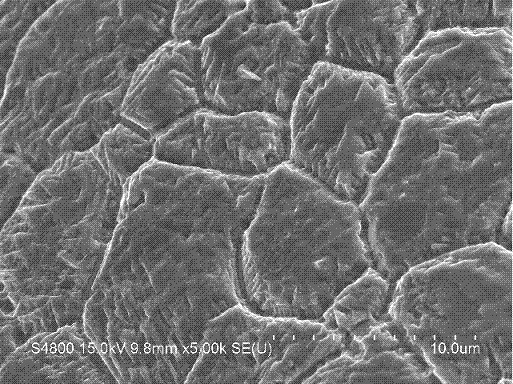

[0019] Weigh 31 mg of graphene oxide, add it into 30 mL of deionized water, and ultrasonically disperse to form a uniform dispersion, then weigh 31 mg of red phosphorus and dissolve it in the above dispersion, and ultrasonicate for 2 hours. The dispersion of graphene oxide and red phosphorus was added to the polytetrafluoroethylene lining of the hydrothermal kettle, and a 1×2 cm 2 The nickel foam is immersed in the dispersion, and the stainless steel jacket is tightened and placed at 180°C for 12 hours. The product was washed, dried and stored for later use. The prepared nickel phosphide / graphene as attached figure 1 shown.

Embodiment 2

[0021] Weigh 31 mg of graphene oxide, add it into 30 mL of deionized water, and ultrasonically disperse to form a uniform dispersion, then weigh 15.5 mg of red phosphorus and dissolve it in the above dispersion, and ultrasonicate for 1 hour. The dispersion of graphene oxide and red phosphorus was added to the polytetrafluoroethylene lining of the hydrothermal kettle, and a 1×2 cm 2 The nickel foam is immersed in the dispersion, and the stainless steel jacket is tightened and then kept at 210°C for 24 hours. The product was washed, dried and stored for later use.

Embodiment 3

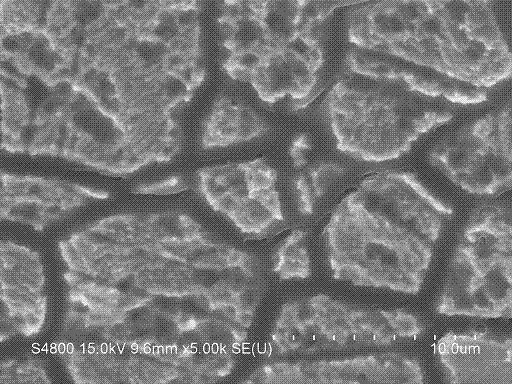

[0023] Weigh 40 mg of graphene oxide, add it into 30 mL of deionized water, and ultrasonically disperse to form a uniform dispersion, then weigh 8 mg of red phosphorus and dissolve it in the above dispersion, and ultrasonicate for 0.5 hours. The dispersion of graphene oxide and red phosphorus was added to the polytetrafluoroethylene lining of the hydrothermal kettle, and a 1×2 cm 2 The nickel foam is immersed in the dispersion, and the stainless steel jacket is tightened and then kept at 150°C for 36 hours. The product was washed, dried and stored for later use. The prepared nickel phosphide / graphene as attached figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com