Counter electrode material of sensitized solar battery and manufacturing method of counter electrode material

A technology for solar cells and electrode materials, applied in photosensitive devices, electrolytic capacitors, circuits, etc., can solve the problems of limited application scope, low photoelectric conversion efficiency, small specific surface area, etc., to alleviate energy shortage, improve photoelectric conversion efficiency, Good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

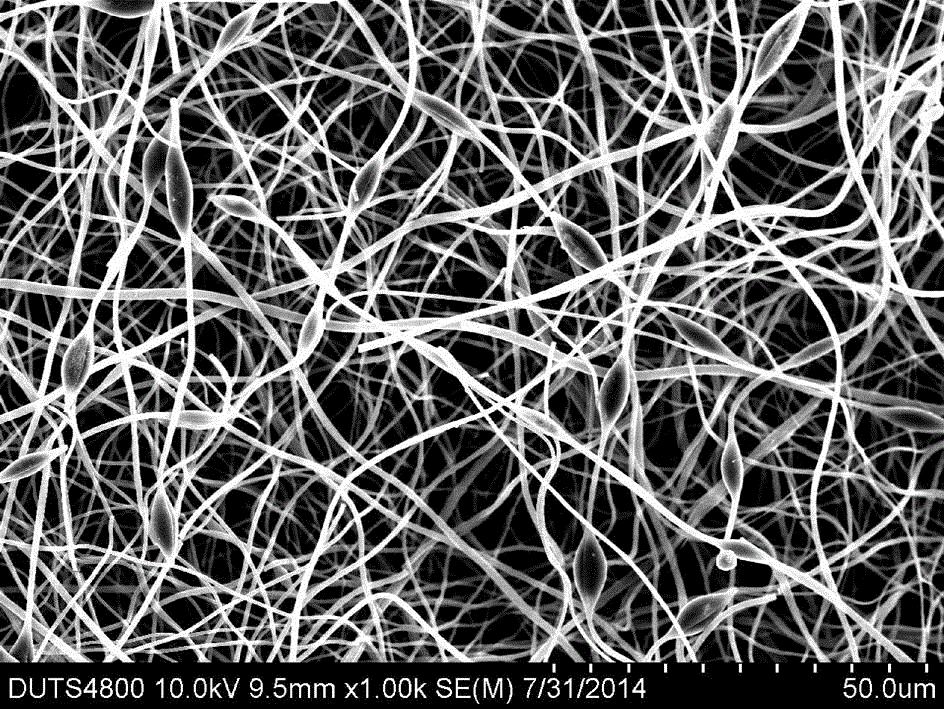

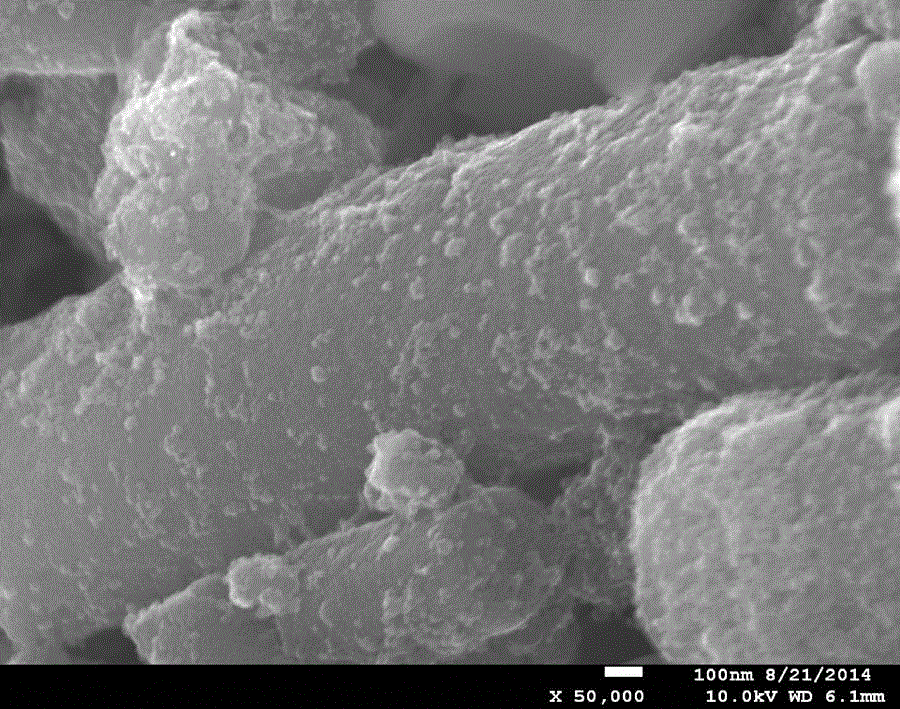

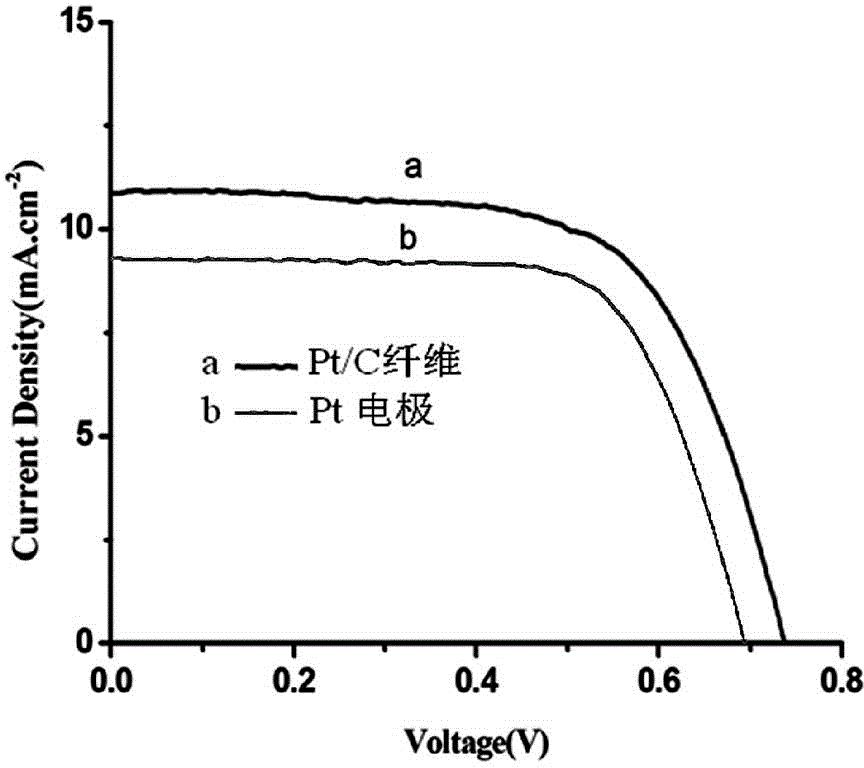

[0027] (1) First dissolve polyacrylonitrile (PAN) in 25mL dimethylformamide (DMF), where the mass percentage of PAN is 15%, stir at room temperature until uniform, transparent and viscous, and then transfer it into a 10 mL syringe , install a needle with a length of about 25 cm and a diameter of about 0.7 mm at the front end of the syringe; turn on the high-voltage electrostatic device, adjust the voltage to 10 kV, start spinning, collect evenly distributed PAN filaments at the receiving plate, and spin the spun PAN The raw silk is placed in a tubular reaction furnace, and the temperature rise rate in the carbonization furnace is adjusted to 1°C / min, so that the carbonization chamber is raised from room temperature to 270°C, and kept for 1 hour to pre-oxidize the polyacrylonitrile; the pre-oxidized polyacrylonitrile Acrylonitrile in N 2 Under protection, control the heating rate at 1°C / min to raise the temperature to 1000°C, cool to room temperature, and prepare polyacrylonitr...

Embodiment 2

[0030] (1) First, dissolve a certain amount of PAN in 25mL of DMF to prepare a PAN mass percentage of 13%, stir at room temperature until it is uniform, transparent and viscous, then transfer it into a 10 mL syringe, and install it on the front end of the syringe A needle with a length of about 25 cm and a diameter of about 0.6 mm; turn on the high-voltage electrostatic device, adjust the voltage to 11 kV, start spinning, collect PAN filaments evenly at the receiving plate, and put the spun PAN precursors in a tubular reactor , the temperature rise rate in the carbonization furnace is adjusted to 1°C / min, and the carbonization chamber is raised from room temperature to 270°C, and kept for 1 hour to pre-oxidize the polyacrylonitrile; the pre-oxidized polyacrylonitrile is placed in N 2 Under protection, control the heating rate of 1 °C / min to 1000 °C, cool to room temperature, and prepare polyacrylonitrile carbon nanofibers, which are black fiber cloth; the average thickness is a...

Embodiment 3

[0033] (1) First dissolve polyacrylonitrile (PAN) in 25mL dimethylformamide (DMF), in which the mass percentage concentration of PAN is 12%, stir at room temperature until uniform, transparent and viscous, and then transfer it into a 10 mL syringe , install a needle with a length of about 25 cm and a diameter of about 0.7 mm at the front end of the syringe; turn on the high-voltage electrostatic device, adjust the voltage to 8 kV, start spinning, and collect the PAN silk evenly at the receiving plate, and the spun PAN raw silk Put it in a tubular reaction furnace, adjust the temperature rise rate in the carbonization furnace to 1°C / min, raise the carbonization chamber from room temperature to 270°C, and keep it for 1 hour to pre-oxidize the polyacrylonitrile; pre-oxidize the polyacrylonitrile in N 2 Under protection, control the heating rate of 1 °C / min to 1000 °C, cool to room temperature, and prepare polyacrylonitrile carbon nanofibers, which are black fiber cloth; the avera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com