An Appearance Abnormality Detection Method of Power Equipment Based on Image Comparison

An anomaly detection and power equipment technology, applied in image enhancement, image analysis, image data processing and other directions, can solve the problems of time-consuming and labor-intensive, increasing the burden of on-site staff, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

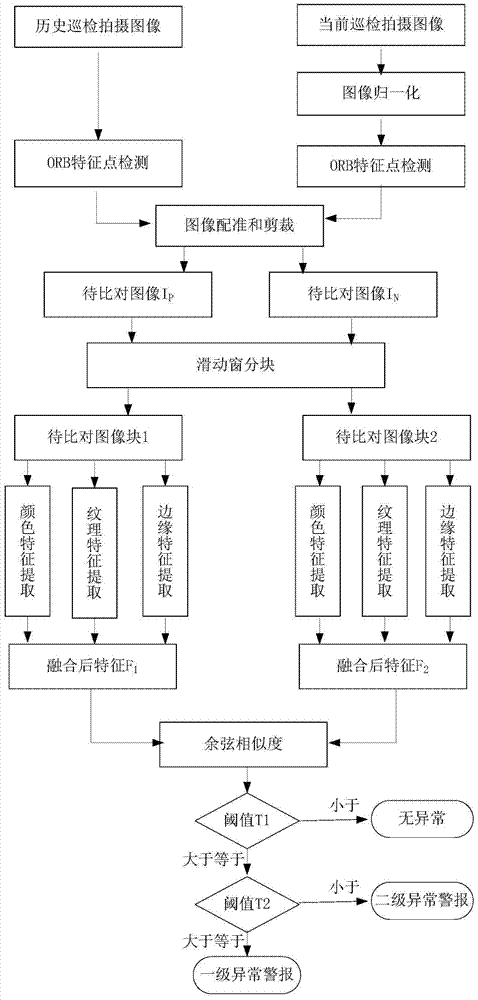

[0076] like figure 1 Shown, method step of the present invention is as follows:

[0077] The first step is to read in the current inspection shooting image I by searching the inspection database 2 And the historical inspection shooting image I compared with it 1 , the two images are images taken by the inspection robot at the same stop and at the same angle.

[0078] The second step is to capture image I with historical inspection 1 For reference, for image I 2 Perform image normalization processing to obtain the normalized image The normalization formula is:

[0079]

[0080] Among them, μ 1 for image I 1 The gray mean value of μ 2 for image I 2 The gray mean value of , σ 1 for image I 1 The gray variance of , σ 2 for image I 2 The gray variance of for the normalized image The gray value of the middle pixel r, I 2 (r) is the orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com