Concrete wall formwork matching method

A concrete wall and concrete technology, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and preparation of building components on site, which can solve the problem of random reinforcement spacing of wooden formwork for concrete walls problems such as high reliability, poor versatility of concrete wall formwork and floor formwork, and large loss of concrete wall formwork, so as to achieve convenient on-site operation and inspection, ensure on-site construction efficiency, and achieve efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

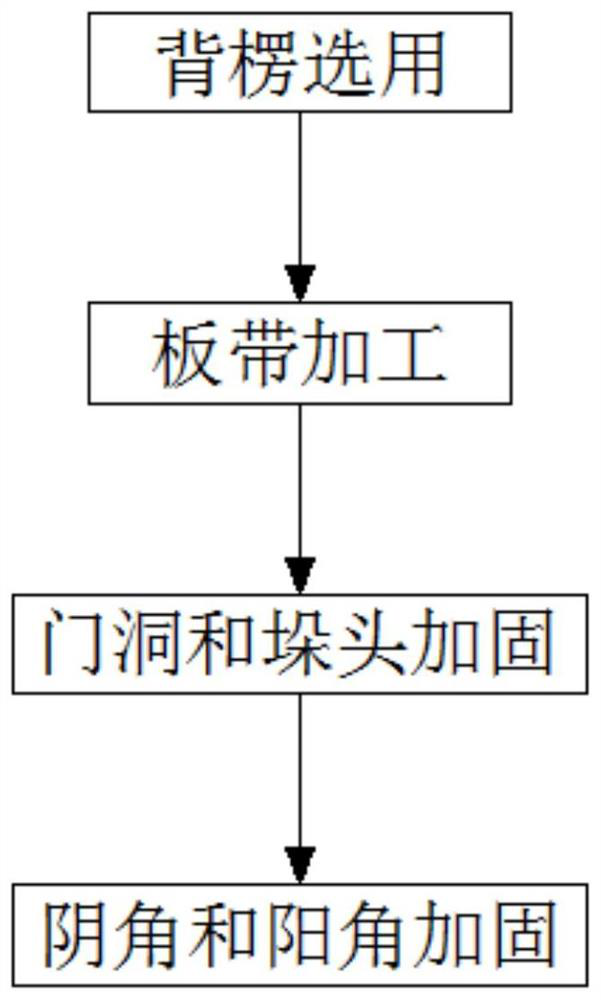

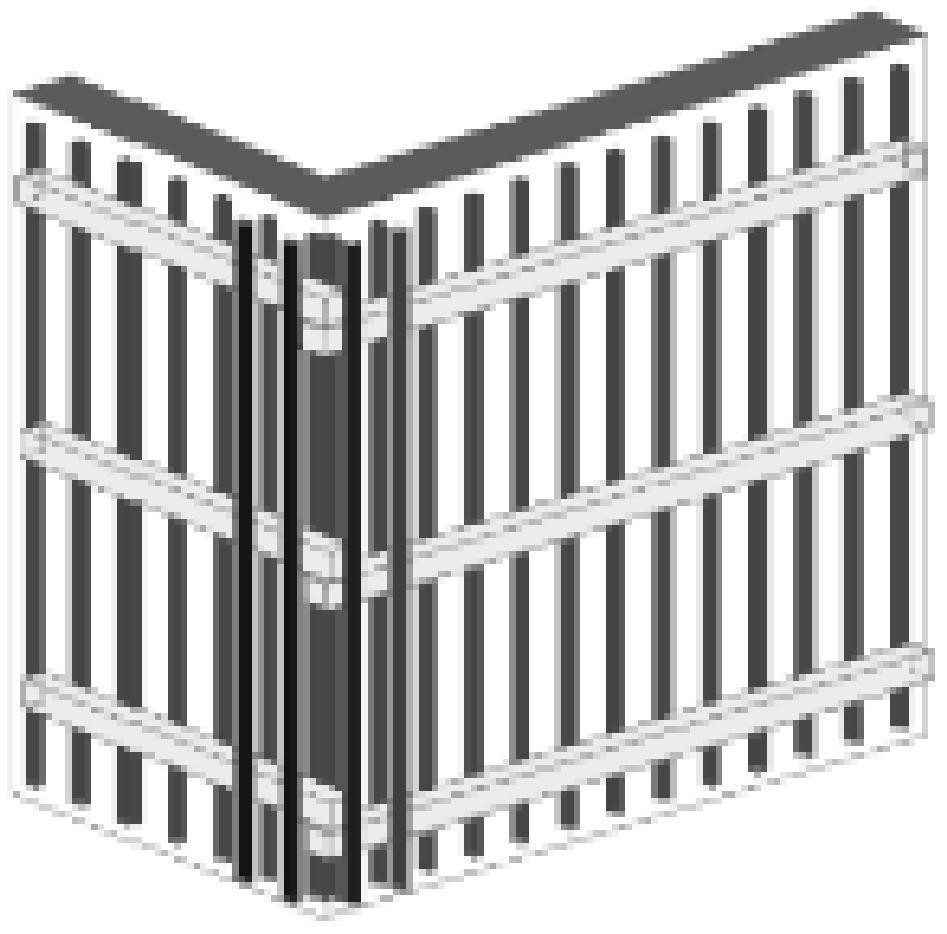

[0029] see figure 1 , the present embodiment provides a concrete wall formwork matching method, comprising the following steps:

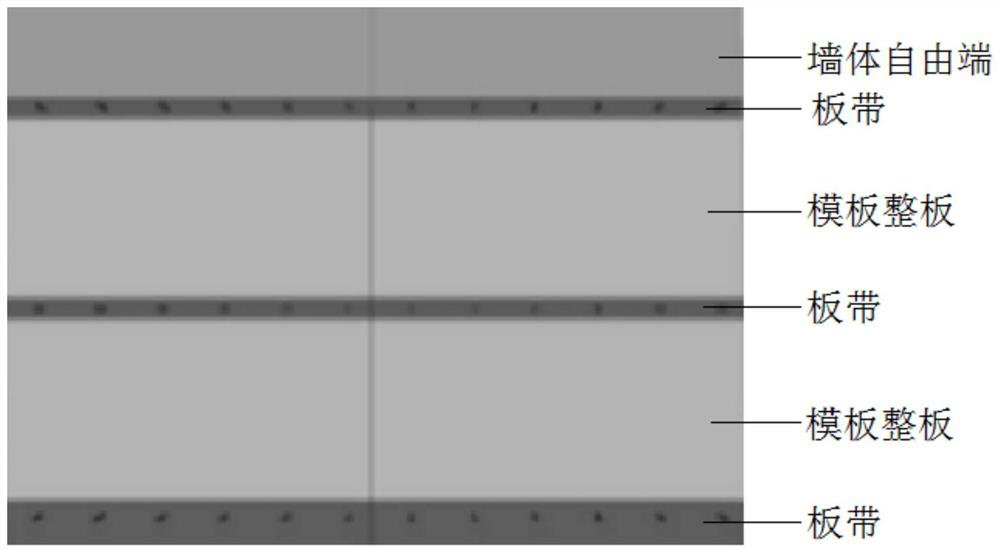

[0030] Step 1: Selection of back corrugated

[0031] First, according to the construction requirements, use the safety calculation software to select steel supports with qualified bending strength and rigidity as the back corrugated material of the concrete wall formwork, and then arrange the specified number of steel supports vertically and equidistantly according to the concrete wall shape according to the concrete wall panel specifications Then fix the horizontally distributed steel supports outside the vertically arranged steel supports. The steel supports are made of cold-rolled steel plates, and the bending strength and rigidity of the steel supports meet the requirement that the bolt spacing is greater than the reinforcement spacing of the entire template. It is required that the steel supports are equidistantly provided with bolt holes acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com