Electrical equipment appearance abnormity detection method based on image comparison

A technology for anomaly detection and power equipment, applied in image enhancement, image analysis, image data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

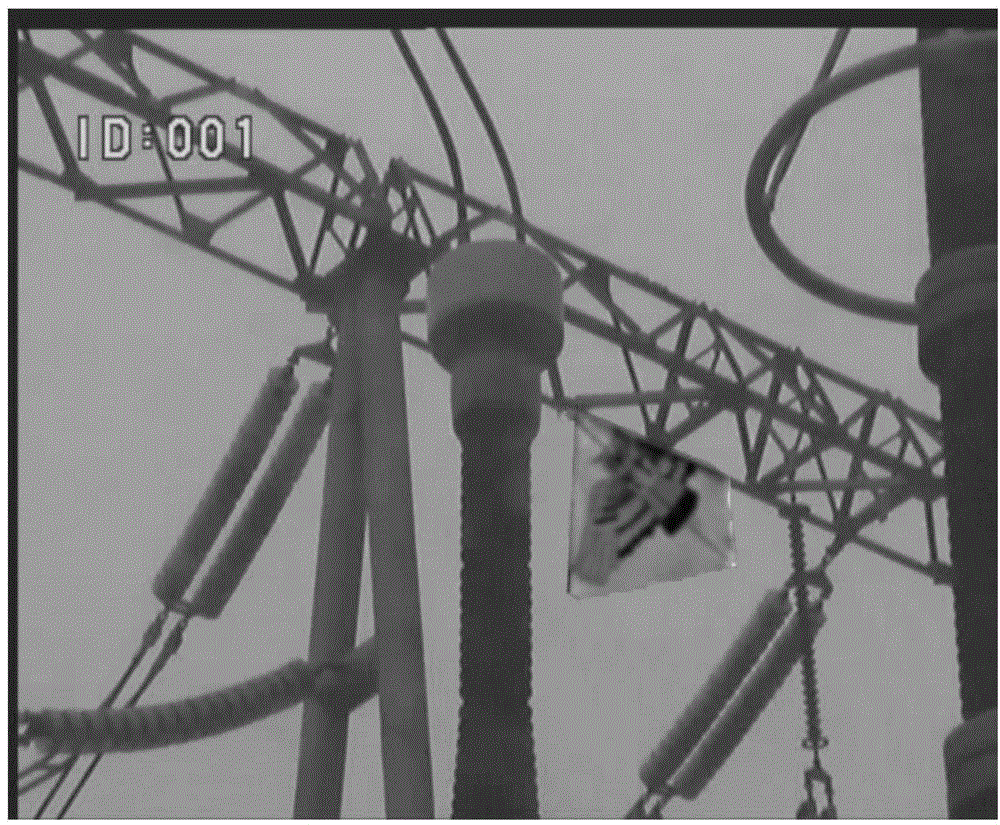

Image

Examples

Embodiment Construction

[0075] The present invention will be further described below in conjunction with the drawings and embodiments.

[0076] Such as figure 1 As shown, the method steps of the present invention are as follows:

[0077] The first step is to read in the current patrol image by searching the patrol database I 2 Compared with the historical inspection image I 1 , The two images are the images taken by the inspection robot at the same stopping point and at the same angle.

[0078] Step 2: Images taken at historical moments I 1 For reference, for image I 2 Perform image normalization processing to get the normalized image I 2 , The normalization formula is:

[0079] I 2 ( r ) = σ 1 σ 2 { I 2 ( r ) - μ 2 } + μ 1

[0080] Among them, μ 1 For image I 1 Mean gray value, μ 2 For image I 2 Mean gray value of σ 1 For image I 1 The gray-scale variance, σ 2 For image I 2 The gray-scale variance, I 2 (r) is the normalized image I 2 Gray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com