Temperature rise test method for multiphase multi-unit permanent magnet motor

A test method, permanent magnet motor technology, applied in the direction of motor generator testing, etc., can solve the problem of energy consumption of the motor for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

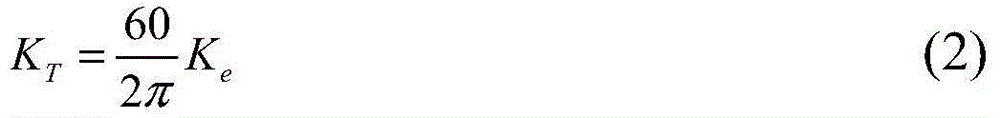

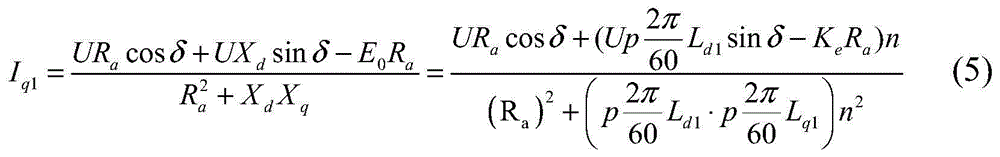

[0032] Specific implementation mode one: its method steps are:

[0033] Step 1: Use a unit of the motor under test for power generation operation, and connect this unit end to the load resistance or the load grid. When connected to the load grid, control the driver to turn off first;

[0034] Step 2: Use another unit of the motor under test for electric operation, connect this unit to the driver, and then control the driver to start running, test the motor speed at this time, the three-phase winding current waveform and the phase resistance voltage value, and from The controller reads the power angle in this state;

[0035] Step 3: Control the driver to stop the motor, and then disconnect the load of the unit used for power generation, and then pass the DC current with the same effective value as the current in the operating state in step 2 into the three-phase windings of the electric unit, and Test the winding terminal voltage to obtain the winding resistance in this state;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com