An automatic steel cord drumming detector

A technology for steel cords and detectors, which is applied to instruments, measuring devices, and mechanical devices, etc., can solve the problems affecting the accuracy of cord drumming, the risk and cost of cord quality, and the detection effect of loose cords. The effect of testing accuracy and stability, saving testing costs, and stabilizing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

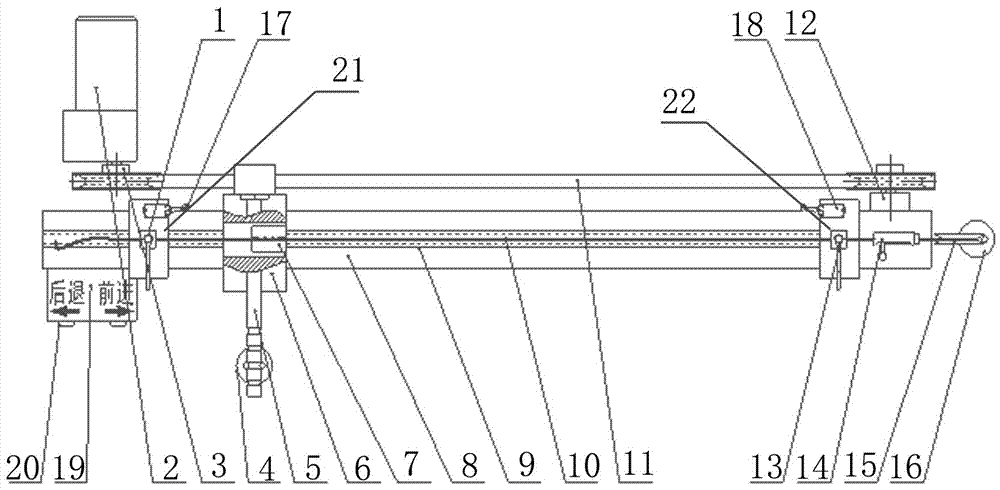

[0008] exist figure 1 Among them, the present invention provides an automatic steel cord drum detection instrument, which includes a motor reduction box 2 and a bracket 8, a guide rail 9 is horizontally arranged on the bracket 8, a moving slider 6 is arranged on the guide rail 9, and the motor The reduction box 2 is located on one side of the head of the bracket 8, and the output shaft of the motor reduction box 2 is connected with the driving pulley 3. Driven pulley 12 is arranged, and driven pulley 12 is positioned at the same side of support 8 with driving pulley 3, is provided with transmission belt 11 between driving pulley 3 and driven pulley 12, and transmission belt 11 is a V-belt, and the moving slide One side of block 6 is connected with driving belt 11, and driving belt pulley 3 drives driving belt 11 to slide, and driving belt 11 drives driven pulley 12 to rotate, and driving belt 11 drives mobile slide block 6 to slide on guide rail 9, and on the other side of mob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com