Steel structure safe fracture toughness determination method and steel structure design safety checking method

A technology of fracture toughness and determination method, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of poor engineering practicability, long test period of strain fracture toughness, cumbersome test process, etc., to prevent excessive plasticity. Deformation failure, safe fracture toughness is accurate and reliable, and the realization process is simple and fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

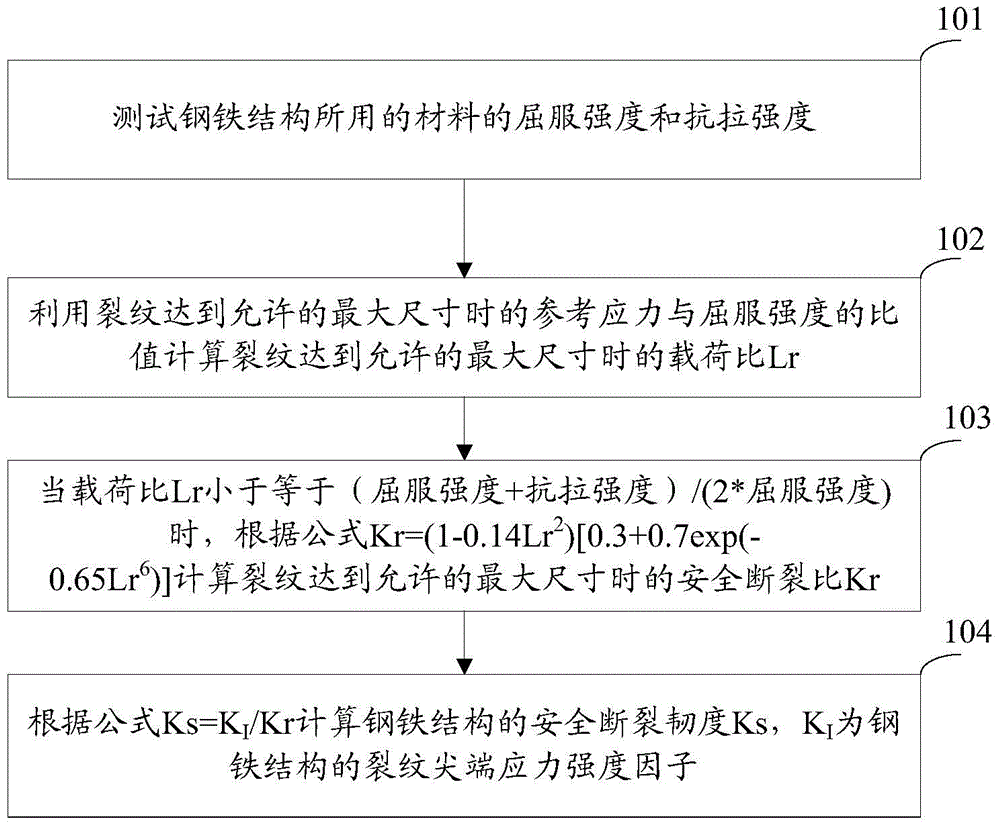

[0040] The embodiment of the present invention provides a method for determining the safe fracture toughness of steel structures, see figure 1 , methods include:

[0041] Step 101: Test the yield strength σ of the material used in the steel structure y and tensile strength σ u .

[0042] Specifically, the yield strength σ of materials used in steel structures can be tested by uniaxial tensile testing y and tensile strength σ u .

[0043] Further, a universal material testing machine can be used to test the yield strength and tensile strength of the materials used in the steel structure.

[0044] Wherein, the steel structure may be a steel plate, section steel or steel pipe, etc.

[0045] Step 102: According to the formula L r =σ ref / σ y Calculate the load ratio L of the steel structure when the crack reaches the maximum allowable size under the design condition r .

[0046] Among them, σ ref It is the reference stress when the crack reaches the maximum allowable s...

Embodiment 2

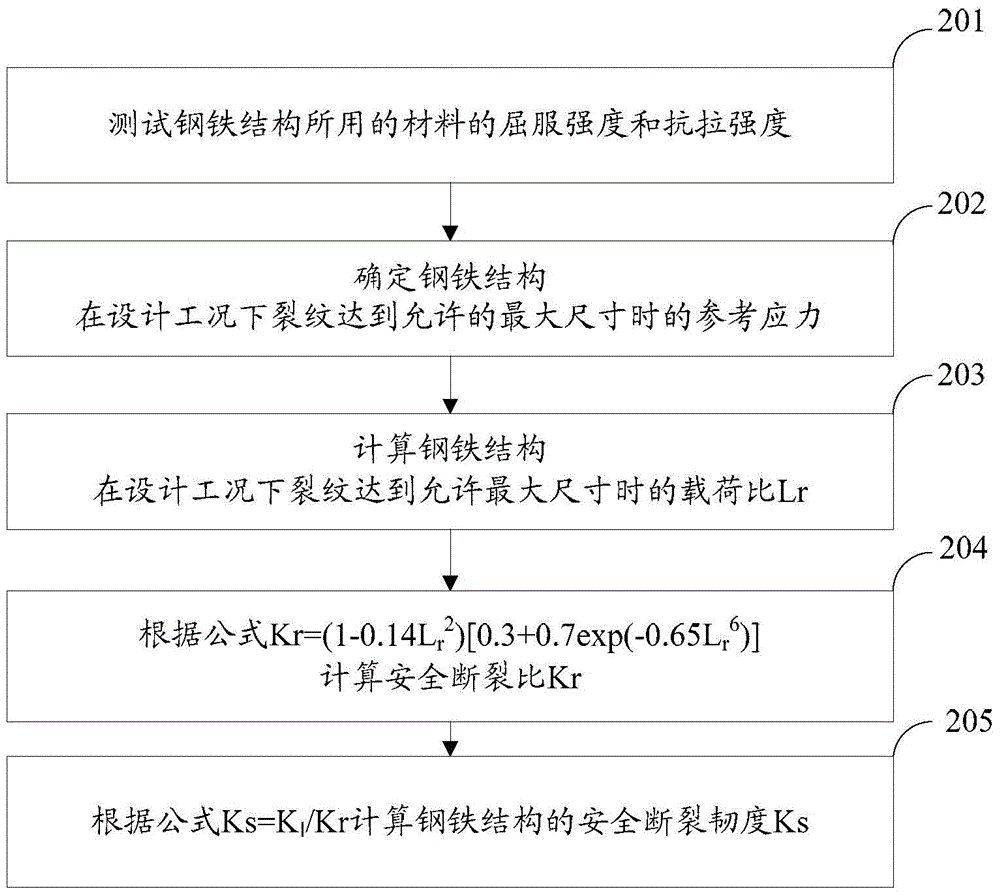

[0052] The embodiment of the present invention provides a method for determining the safe fracture toughness of steel structures, see figure 2 , methods include:

[0053] Step 201: Test the yield strength σ of the material used in the steel structure y and tensile strength σ u .

[0054] Among them, the yield strength σ y and tensile strength σ u It can be measured by ordinary uniaxial tensile test, and can be tested by universal material testing machine (or electronic universal material testing machine).

[0055] In this embodiment, before step 201 , samples of materials used in steel structures are obtained. The test specimen is usually an ordinary tensile test specimen.

[0056] Step 202: Determine the reference stress σ when the crack reaches the maximum allowable size in the steel structure under design conditions ref .

[0057] In practical applications, you can refer to relevant standards in the field (such as API579-1-2007), manuals or literature to select the...

Embodiment 3

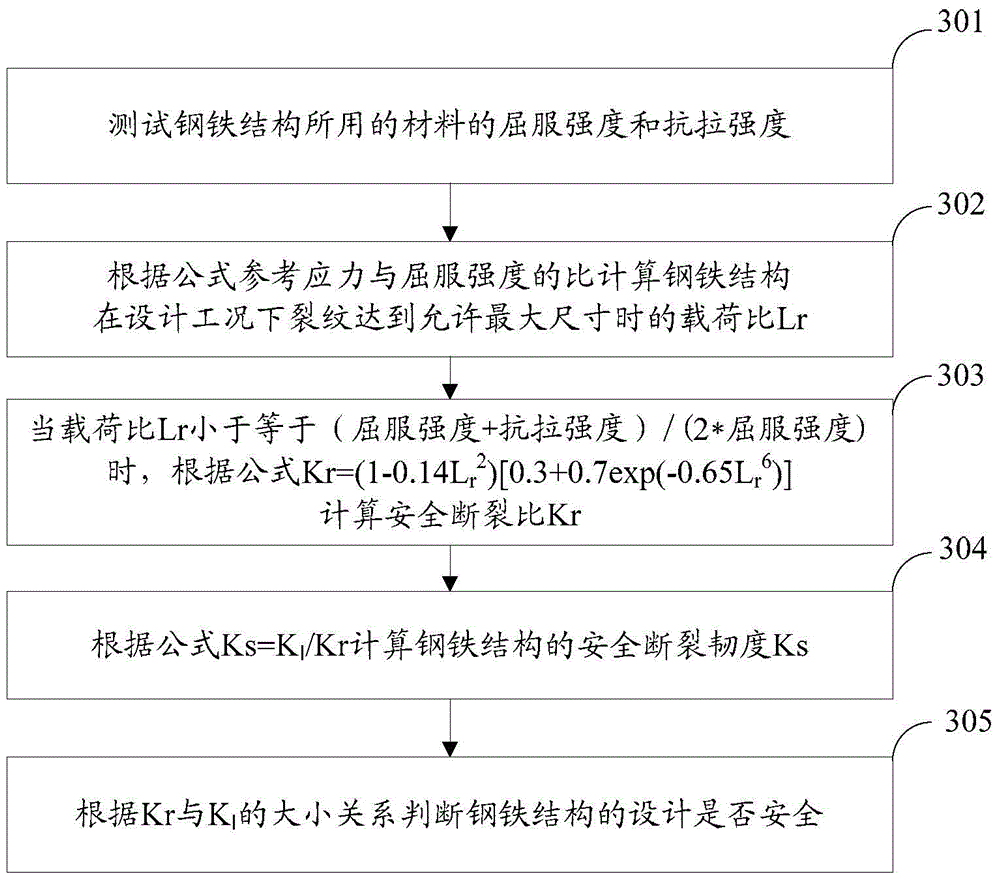

[0086] The embodiment of the present invention provides a safety check method for steel structure design, see image 3 , the method includes:

[0087] Step 301: Test the yield strength σ of the material used in the steel structure y and tensile strength σ u .

[0088] Wherein, the steel structure may be a steel plate, section steel or steel pipe, etc.

[0089] Step 302: According to the formula L r =σ ref / σ y Calculate the load ratio L of the steel structure when the crack reaches the maximum allowable size under the design condition r .

[0090] Among them, σ ref It is the reference stress when the crack reaches the maximum allowable size of the steel structure under the design condition.

[0091] Step 303: When the load ratio L r meet L r ≤(σ y +σ u ) / (2·σ y ), according to the formula K r =(1-0.14L r 2 )[0.3+0.7exp(-0.65L r 6 )] Calculate the safe fracture ratio K of the steel structure when the crack reaches the maximum allowable size under the design c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com