Non-contact ground stress testing device and method based on drilling microscopic digital camera

A test device, non-contact technology, applied in the direction of measuring devices, measuring force, instruments, etc., can solve the problems of electromagnetic interference, harsh environmental requirements, probes can not be reused, etc., to achieve strong anti-interference ability, strong adaptability, The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

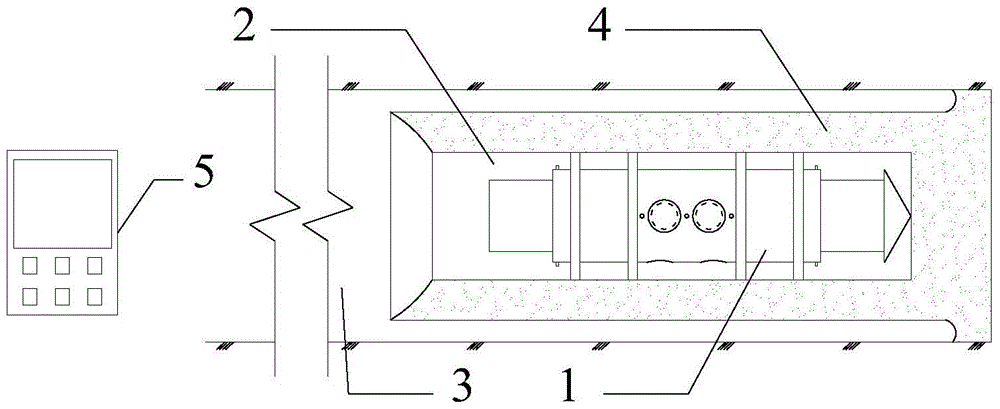

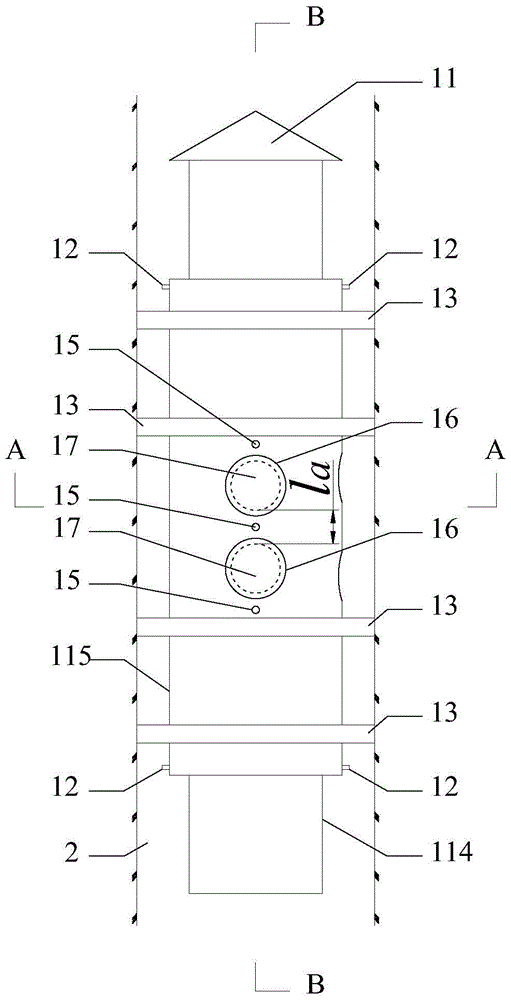

[0054] Example 1: The non-contact ground stress test device 1 is located in the test device installation hole 2, the test device installation hole 2 is located in the initial large diameter hole 3, the test device installation hole 2 and the initial large diameter hole 3 In between is the lifted core 4, and the main engine 5 is located outside the initial large-diameter borehole 3;

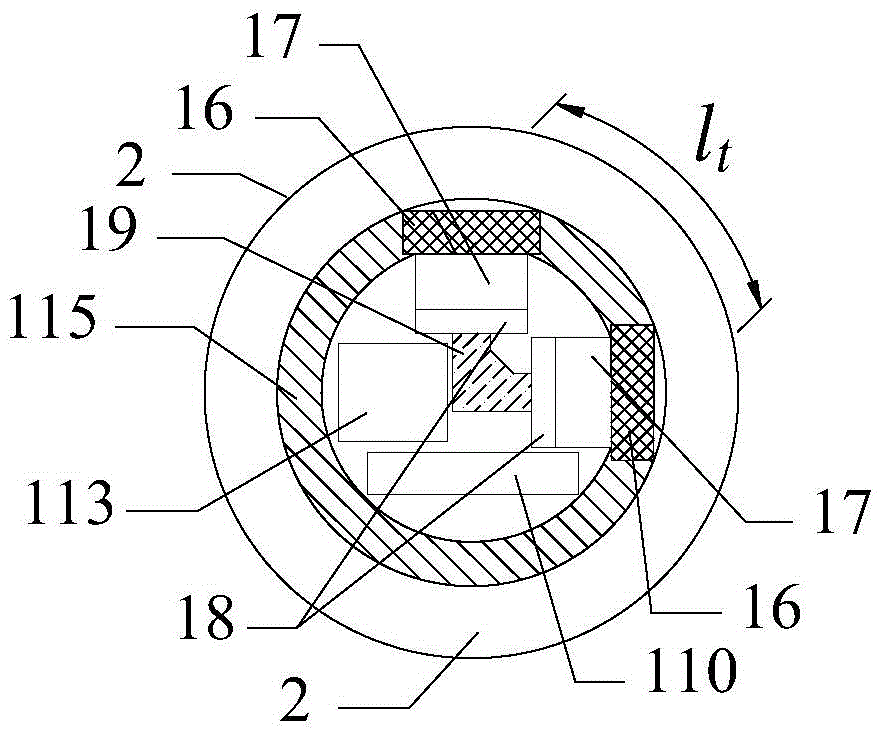

[0055] The non-contact ground stress testing device 1 includes: an electronic microscope camera 17, a lighting lamp 15, a signal processing and control module 111, a signal transmission module 112, a gyroscope 113, a signal acquisition module 18, a mobile power supply 110 and a device housing 115; At both ends of the device housing 115 are respectively connected the guide piston 11 and the device connector and the rear piston 114; the device housing 115 is provided with an electronic microscope camera 17, electronic microscope camera 17, gyroscope 113, signal transmission module 112 Connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com