Quick phototyping by laser cladding layer height measuring device and closed-loop control method thereof

A laser cladding and measurement device technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problems of unstable molten pool images and easy to be blocked, so as to reduce cladding layer defects and ensure accurate measurement and control processes , The effect of uniform microstructure and morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

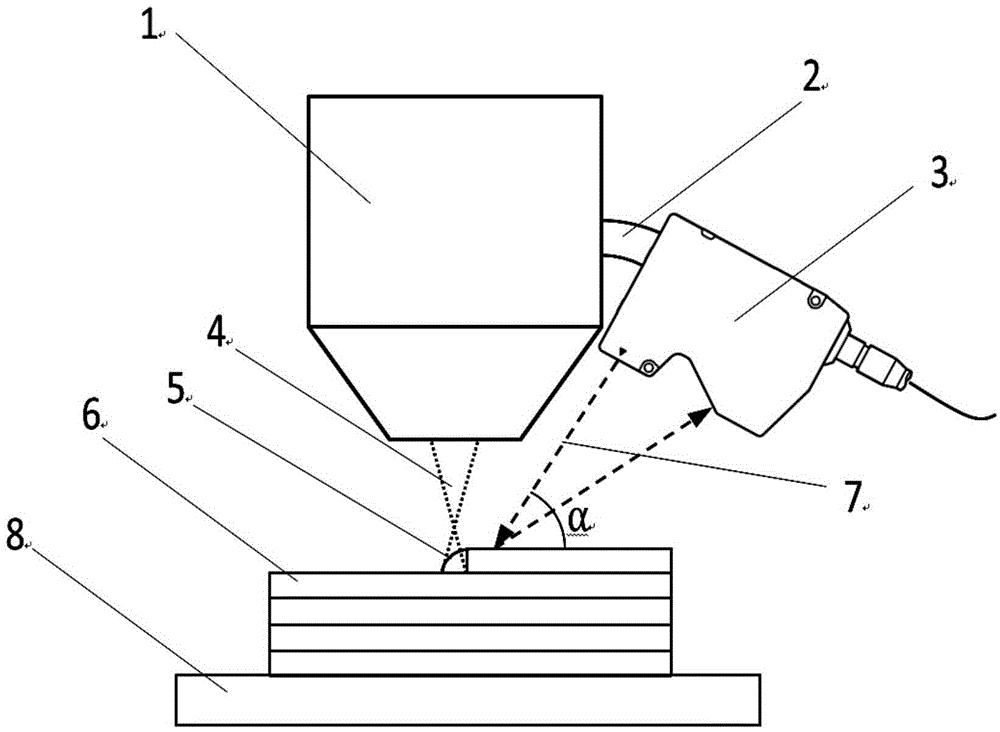

[0042] Example: Laser cladding forming and stacking a thin-walled curved part.

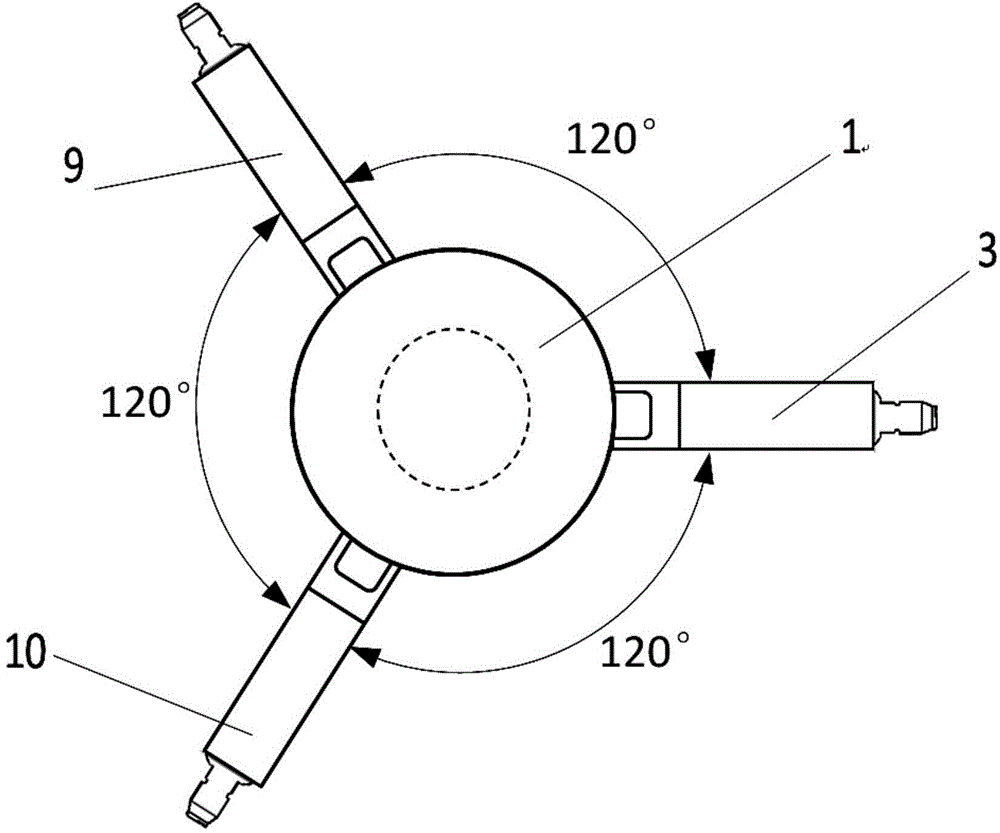

[0043] Set the laser power to 600W, the cladding head scanning speed to 6mm / s, the powder feeder carrier gas flow rate to 3L / min, the powder feed rate to 7.5g / min, and the protection air pressure to 1.5bar. Adjust the defocus of the cladding head to -3mm to make the spot diameter 2.5mm. There is only one scanning direction. The laser cladding rapid prototyping layer height measuring device and the closed-loop control method of the present invention are used to make one side of the laser equilateral triangle perpendicular to the scanning direction. Set the sensor sampling frequency to 1000 Hz, and the side length of the laser equilateral triangle to 12 mm. The 10 points of the highest point area of the measurement are in the middle of the C vector and are at C 350 -C 420 between. The defocus is stabilized at about -3mm through the closed-loop control method. The surface of the formed part obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com