A Helix Angle Measuring Method for Spiral Bevel Gears

A technology of a spiral bevel gear and a measuring method, applied in the field of gear processing, can solve the problems of complicated operation process of the measuring method, and achieve the effects of simplifying measuring steps, improving transmission stability and force uniformity, and simple measuring tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

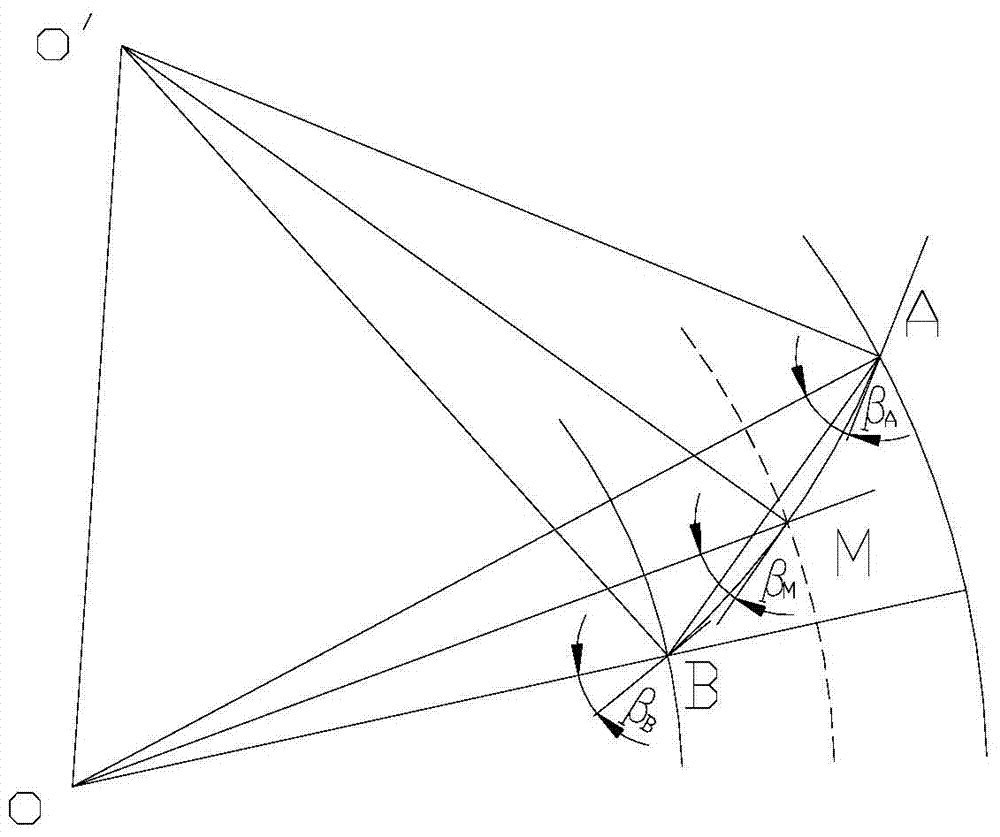

[0038] see figure 1 As shown, a method for measuring the helix angle of a spiral bevel gear of the present invention, the method specifically includes the following steps:

[0039] Step 1. Use the height ruler to determine the intersection point between the small end and large end edge of any tooth and a node circle. The two intersection points are marked as A and B respectively, the vertex of the pitch cone circle is O, and the center of the cutterhead is O'.

[0040] Step 2, measure the straight-line distance between the two intersection points A and B with a vernier caliper;

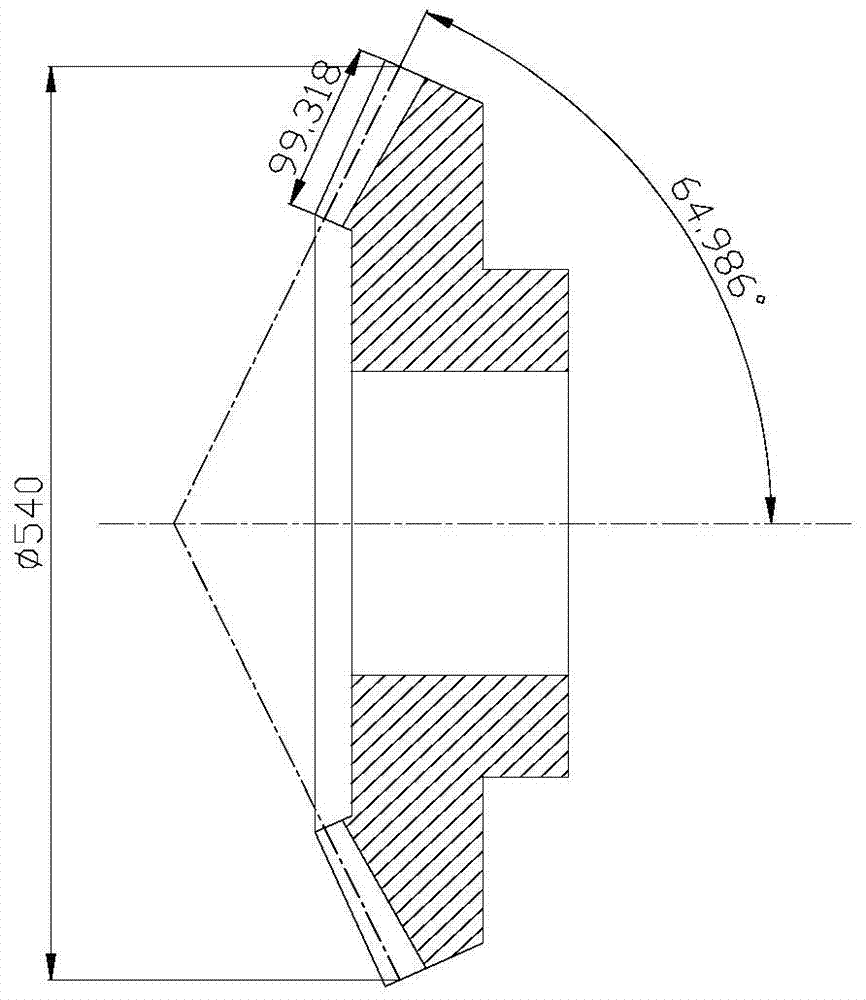

[0041] Step 3. Obtain parameters from the design parameters of the spiral bevel gear: outer cone distance L A , tooth width b, the value of the nominal radius r of the cutter head; and from the outer taper distance L A and tooth width b to obtain the inner taper distance L B , midpoint cone distance L M ;

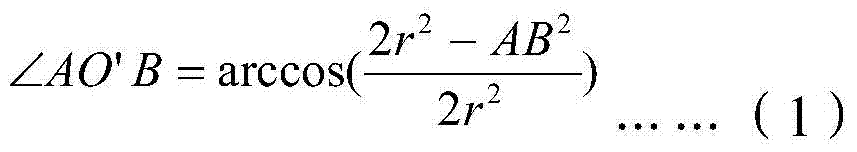

[0042] Step 4. According to the relationship between angles and sides, obtain the values ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com