Cold platform of Stirling cryocooler

A cold platform and refrigerator technology, which is applied in refrigerators, refrigeration and liquefaction, compressors, etc., can solve the requirements of small cooling capacity, small head surface area, and cannot meet the temperature uniformity requirements of transmission detector chips with large cooling capacity, etc. problem, to achieve the effect of reducing impact and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with the drawings:

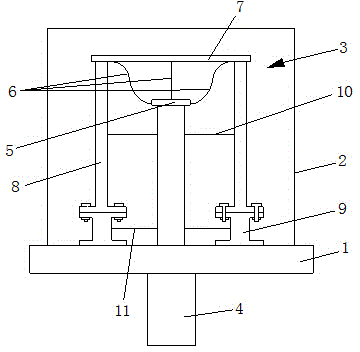

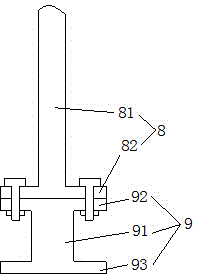

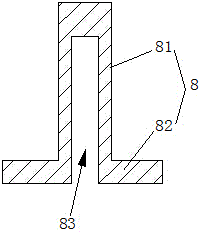

[0018] Such as figure 1 The cold platform of a Stirling refrigerator shown includes a closed vacuum space 3 composed of a transition flange 1 and a Dewar 2. The expander 4 is fixed on the transition flange 1 and the cold head 5 of the expander 4 is located In the enclosed vacuum space 3, the cold head 5 is connected to the cold plate 7 through a flexible cold chain 6, and a supporting device is provided between the cold plate 7 and the transition flange 1 to connect the two.

[0019] Further, such as Figure 4 As shown, the upper plate surface of the cold plate 7 is coupled with the detector chip, the lower plate surface of the cold plate 7 and the cold head 5 are connected by three flexible cold chains 6, and the three flexible cold chains 6 are respectively connected to the lower plate surface of the cold plate 5. The two ends of the flexible cold chain 6 are rigidly connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com