A condensate collector for easy gas-liquid-solid separation

A gas-liquid-solid separation and condensate technology, which is used in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc. Realize problems such as gas recovery, and achieve the effect of reducing operating costs and transportation costs, reducing transportation difficulties, and improving gas purification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

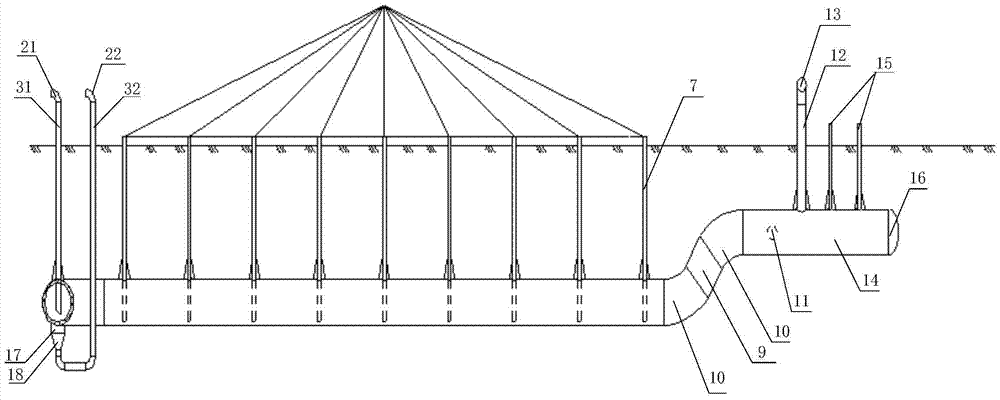

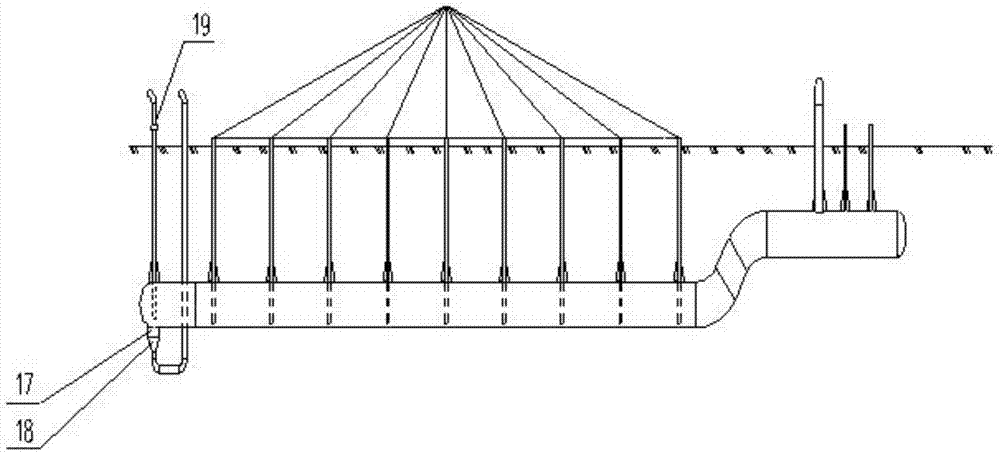

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] This embodiment provides a condensate collector that is convenient for gas-liquid-solid separation. The condensate collector is designed separately and assembled on site, that is, the connecting pipes and pipe fittings of the condensate collector are designed and processed separately, and then transported to On-site and on-site trunk steel pipes are welded with openings.

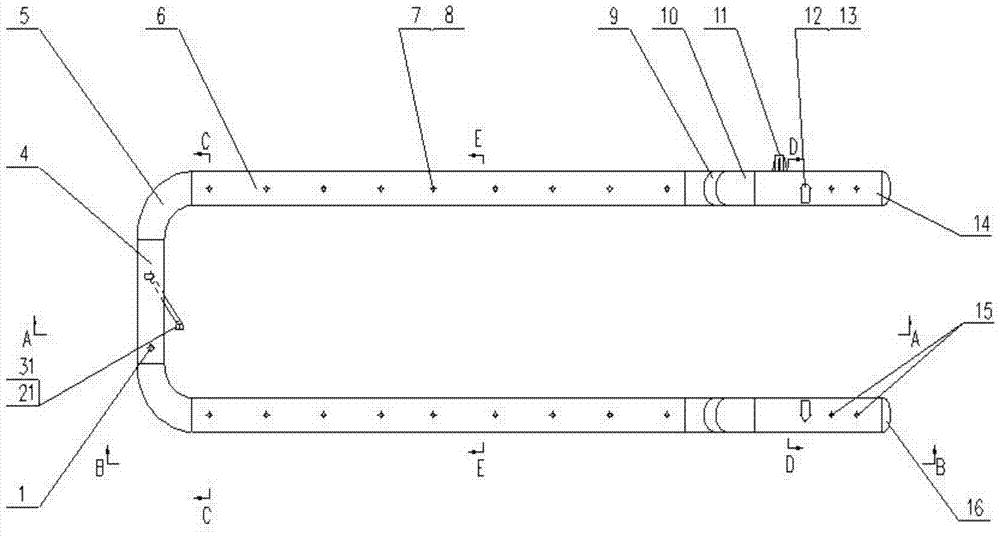

[0021] see Figure 1 to Figure 6 , the condensate collector that is convenient for gas-liquid-solid separation provided in this embodiment includes a liquid level gauge connecting pipe 1, a loading pipeline connecting elbow 21, a loading pipeline connecting pipe 31, a loading pipeline connecting pipe 32, and a loading pipeline connecting pipe Elbow 22, liquid collecting steel pipe 4, 90 degree elbow 5, connecting steel pipe 6, purge pipeline connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com