Filtering and backwashing system for agricultural irrigation

An agricultural irrigation and backwashing technology, which is applied in the direction of filtration separation, filtration circuit, separation method, etc., can solve the problems of filtration effect and efficiency decline, affect the normal operation of the system, and poor filtration, etc., and achieve high backwashing efficiency and sewage discharge capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

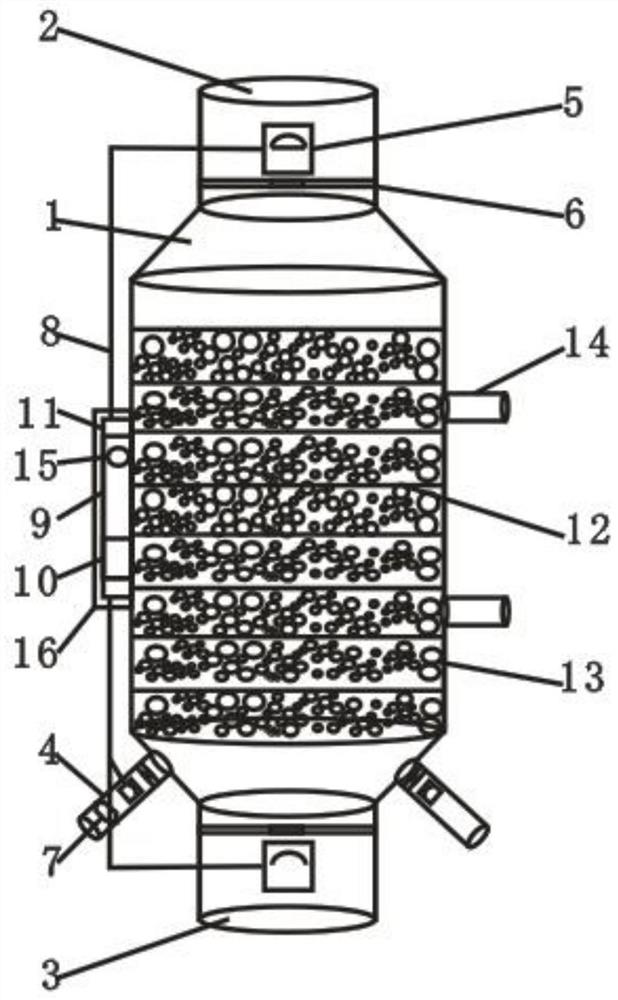

[0018] see figure 1 , the present invention provides a technical solution: an agricultural irrigation filtering and backwashing system, comprising a tank body 1, a water inlet 2 and a water outlet 3 are respectively installed at both ends of the tank body 1, and the water inlet 2 is arranged directly above the water outlet 3 , both sides of the water outlet 3 are equipped with a backwash water inlet pipe 4, and a pressure converter 11 is also installed between the electronic pressure gauge 5 between the water inlet 2 and the water outlet 3 and the microprocessor 9, and the microprocessor 9 is installed on the outer wall of the side of the tank body 1. Both ends of the tank body 1 are made into a circular platform shape. Several layers of filter plates 12 are installed inside the tank body 1. The number of filter plates 12 is 2-10 layers. Between the filter plates 12 Parallel to each other, and the distance between each filter plate 12 is 500mm, the filter plate 11 is movable w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com