Anti-subsidence plastic double-head hoop telescopic joint for buried

An expansion joint and anti-settlement technology, which is applied in the direction of pipes/pipe joints/fittings, pipeline connection layout, mechanical equipment, etc., can solve problems such as no solution, and achieve the effect of improving sealing safety performance and anti-settling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

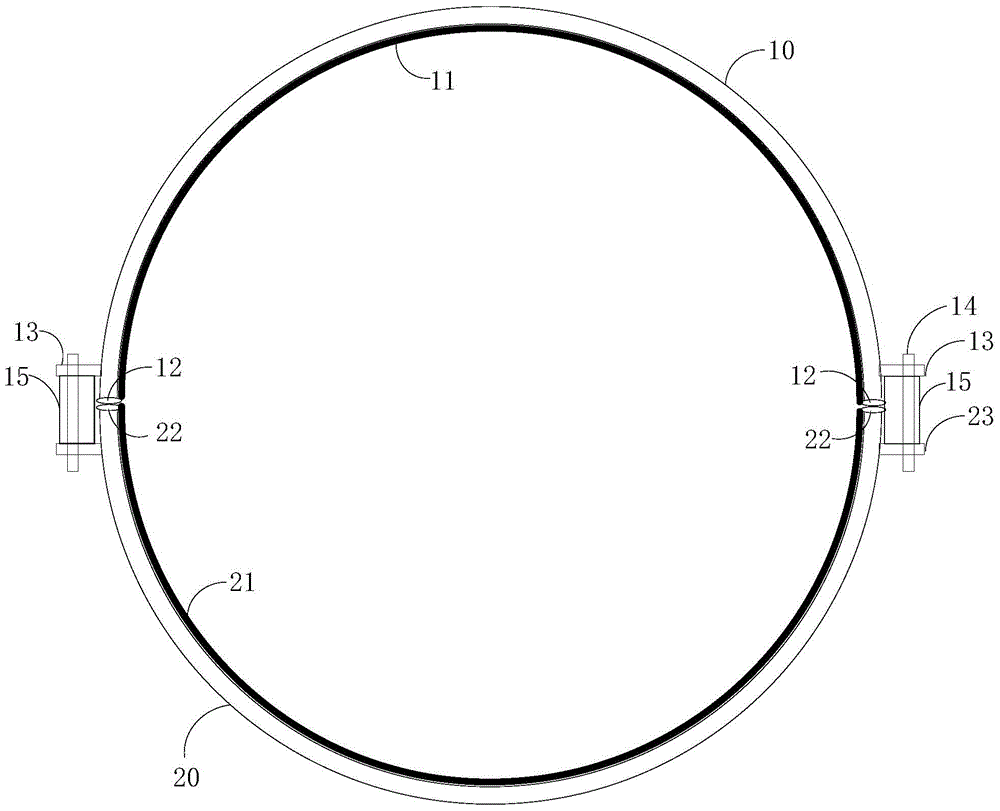

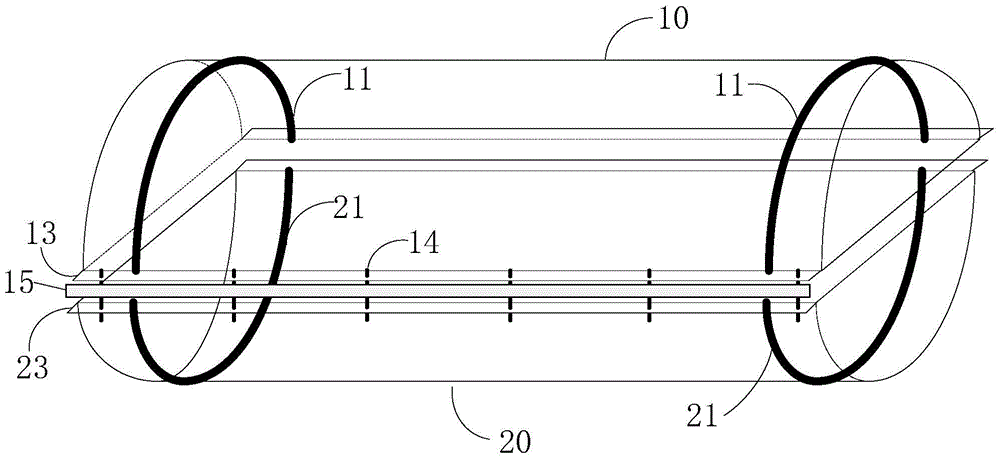

[0031] see Figure 1 to Figure 3 , the present invention discloses an anti-subsidence plastic double-headed hoop telescopic joint for buried ground, the telescopic joint includes: a first hoop unit 10 and a second hoop unit 20 .

[0032] The first hoop unit 10 and the second hoop unit 20 both include a hoop unit main body with a semicircular radial section, and at least one groove is respectively provided at both axial ends of the hoop unit main body. Sealing strips 11, 21 are installed.

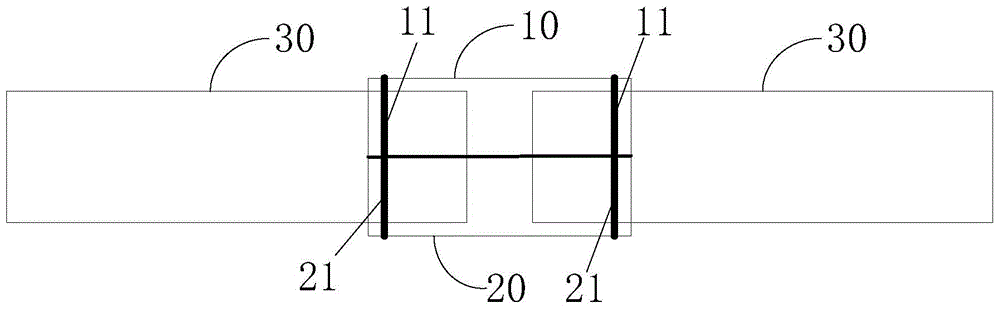

[0033] The first hoop unit 10 and the second hoop unit 20 are tightly hugged to form a hollow cylinder, which tightly hugs two adjacent drainage pipes 30, and the sealing strips 11 and 21 arranged at both ends are respectively arranged on the two The outer walls of adjacent drain pipes 30 make the gap area between two adjacent drain pipes 30 sealed.

[0034] The first hoop unit 10 and the second hoop unit 20 are provided with gaskets 12 and 22 at the contact points, and the gaskets 12 and ...

Embodiment 2

[0038] An anti-subsidence plastic double-headed hoop expansion joint for buried ground, the expansion joint is set between two adjacent drainage pipes with a gap between them;

[0039] The expansion joint includes at least one hoop unit; the hoop unit includes a main body of the hoop unit, and at least one sealing mechanism is respectively provided at both ends of the main body of the hoop unit;

[0040] The sealing mechanisms at both ends of the main body of the hoop unit are respectively arranged at one end of two adjacent drainage pipes, so that the gap area between the two adjacent drainage pipes is sealed.

Embodiment 3

[0042] The difference between this embodiment and Embodiment 1 is that in this embodiment, the telescopic joint includes more than three hoop units, and each hoop unit hugs tightly to form a surface of a cylinder.

[0043] A second sealing mechanism is provided where the axial side of the hoop unit contacts the axial side of other hoop units or the other axial side of the hoop unit.

[0044] A locking mechanism is provided at the contact between the axial side of the hoop unit and the axial side of other hoop units or the other axial side of the hoop unit, and the corresponding two hoop units are fixed and locked. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com