Prefabricated integrated pipe gallery and construction method

An integrated pipe gallery and prefabricated panel technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of large raw material storage and processing sites, high construction management costs, waste of templates and labor, and reduce waste of resources. , The effect of good product quality and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

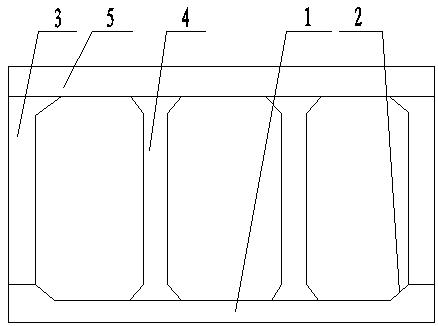

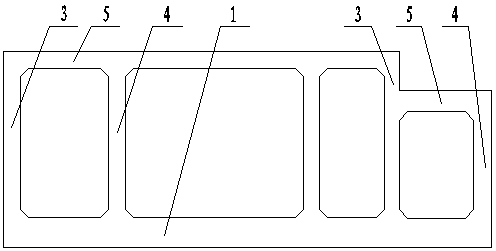

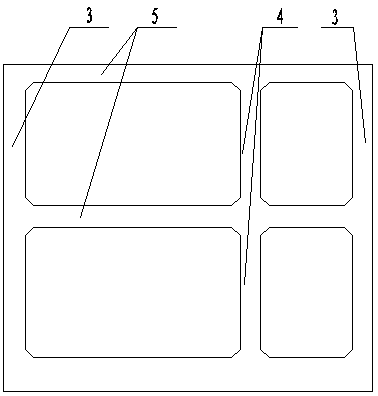

[0038] A prefabricated comprehensive pipe gallery, which consists of: a prefabricated base plate 1, a set of exterior wall bases 2 are arranged on the prefabricated base plate, the external wall bases are connected with a prefabricated external wall 3, and the prefabricated base plate The middle part is connected with a group of prefabricated inner walls 4 , and the tops of the prefabricated outer walls and the prefabricated inner walls are connected with the prefabricated roof 5 .

Embodiment 2

[0040] According to the prefabricated comprehensive pipe gallery described in Example 1, the two ends of the outer wall base and the prefabricated inner wall are provided with axillary corners 6, and the axillary corners are provided with axillary corner ribs 7 , the outer wall base is provided with a waterproof guide groove 8 or a water-stop steel plate 9. When the width of the prefabricated bottom plate is too large, the prefabricated bottom plate is prefabricated in blocks, and the exposed steel bars 10 can be thrown out at the splicing positions of each block. During on-site installation, The exposed steel bars are connected by grouting sleeves, welded, lapped, mechanically connected or other steel bar connections, and the concrete 13 is poured so that the bottom plates are connected together and have a structural waterproof function; prestressed tendons can also be used between the block prefabricated bottom plates Connecting joints, bolted joints and socket joints 11 and ...

Embodiment 3

[0042] According to the prefabricated comprehensive pipe gallery described in embodiment 1, the prefabricated outer wall adopts the form of prefabricated solid concrete shear wall or prefabricated laminated slab concrete shear wall, and when the form of prefabricated laminated slab concrete shear wall is adopted, The interior of the prefabricated concrete part includes shear wall transverse reinforcement and shear wall longitudinal reinforcement 12, and the connection between the two laminated slabs is realized through lattice reinforcement. , welding, lap joint, mechanical connection or other steel bar connection forms, the connection position should reserve holes 14 at the bottom of the wall according to the needs of the steel bar connection form, and the side of the laminated board installed on the top of the wall should be provided with an axillary angle. When crossing the slab, the wall leaves a hole 15 at the position of the low-span slab, and the steel bars are set norma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com