Method for extracting germanium by thermally reducing and volatilizing germanium ores

A technology of germanium ore and fire method, which is applied in the field of germanium ore thermal reduction and volatilization to extract germanium, can solve the problems of promoting germanium volatilization and low carbon content, and achieve the effects of reducing volatilization time, improving recovery rate, and saving mixed combustion fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

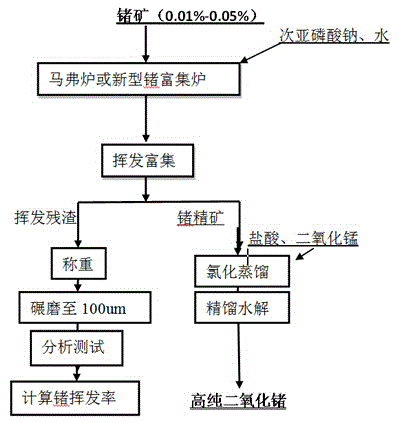

Method used

Image

Examples

Embodiment Construction

[0026] Implementation example 1:

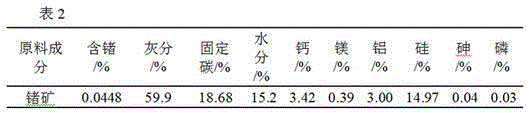

[0027] The ingredients used are listed in Table 2.

[0028]

[0029] In the first step, weigh 50 g of germanium ore shown in Table 2 and add it to an ash dish; weigh 2.5 g of sodium hypophosphite to be added (accounting for 5% of the weight of germanium ore) and add it to a small beaker, and add 25 mL Dissolve it in water, then add it to the sample and mix it evenly with a glass rod, then wash the small beaker and glass rod with 10 mL of water and add it to the sample, then put the sample in an oven pre-heated to 90°C for 30 minutes to evaporate Lose a lot of water until almost dry.

[0030] In the second step, the sample was taken out of the oven and placed in a muffle furnace heated to 900 °C in advance, and then rapidly heated to 1000 °C for constant temperature roasting and volatilization for 1 h.

[0031] In the third step, after roasting and volatilization, cool down to 500°C, take out the ash dish and cool it to room temperature, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com