Nanometer carbon-coated boron nitride composite powder and its preparation method and use

A composite powder and boron nitride technology, which is applied in nitrogen compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problem that the infrared radiation characteristics of nano-carbon materials cannot be well utilized, and various heat dissipation modes cannot be fully utilized. Infrared radiation rate Low-level problems, achieve good thermal conductivity, maintain thermal conductivity, and high infrared radiation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] In a typical implementation case, the preparation method may include the following steps:

[0041](1) Functionalization of nano-carbon materials: reflux nano-carbon materials in 2-8 M concentrated nitric acid solution at 100-140°C for 1-24 h, filter and wash until neutral to prepare carboxylated nano-carbon materials, collect Standby; Wherein, nano-carbon material can adopt various types of carbon nanotubes and graphene materials of various forms, for example, graphene, graphene microplate etc., and graphene material also can directly select graphene oxide for use;

[0042] (2) Disperse the boron nitride powder in an anhydrous solvent, add an amino coupling agent accounting for 1-30% of the weight of the boron nitride powder, mix and stir for 1-24h, then stir at 70-100°C for 30min-1h , collected by filtration and prepared to obtain amino-functionalized boron nitride powder;

[0043] (3) Disperse the carboxylated nano-carbon material in water, gradually add amino-functi...

Embodiment 1

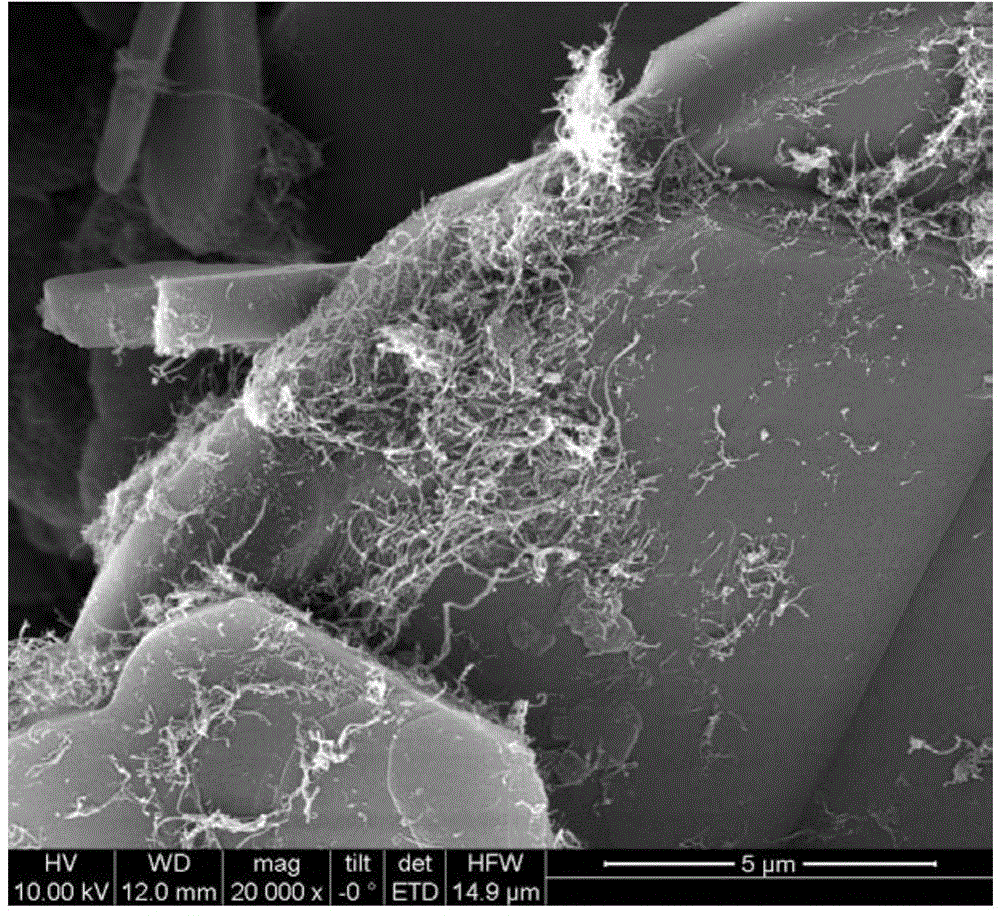

[0049] 1 g of multi-walled carbon nanotubes (diameter 20 nm, length 15 μm) was refluxed at 120 °C for 6 h in a 6 M nitric acid solution, filtered and washed until neutral to obtain carboxylated multi-walled carbon nanotubes, and then ultrasonically dispersed in Reserve in water. At the same time, 10 g of boron nitride powder (hexagonal boron nitride, average particle size 15 μm) was dispersed in absolute ethanol with high-speed stirring, and 2 g of KH550 coupling agent was added dropwise during the stirring process, stirred for 6 hours, and then Heat up to 70°C and reflux for 30 minutes, filter and wash excess coupling agent to obtain amino-functionalized boron nitride. Next, disperse the amino-functionalized boron nitride in water, add carboxylated multi-walled carbon nanotube dispersion liquid during the stirring process, mix and stir for 1 hour, filter and wash, and vacuum-dry at 60°C for 4 hours to obtain multi-walled carbon nanotube-wrapped boron nitride Composite powder...

Embodiment 2

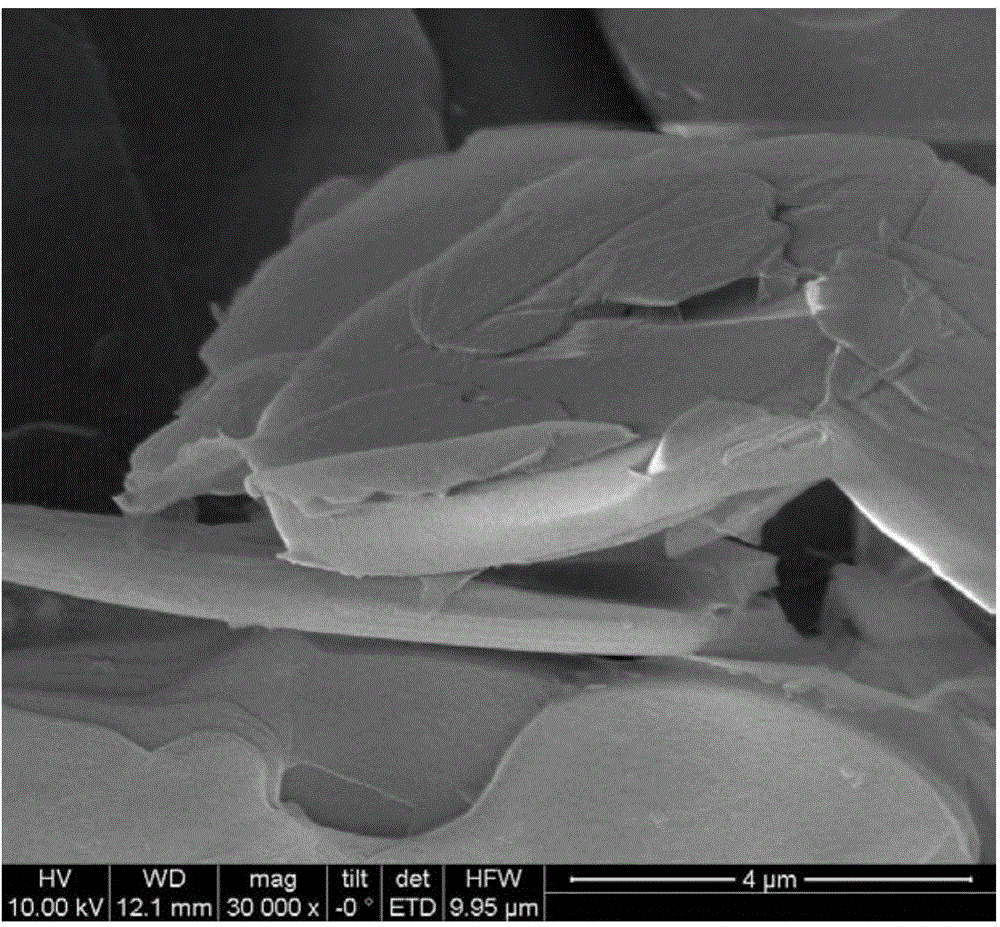

[0051] 1 g single-walled carbon nanotubes (diameter 20 nm, length 15 μm) were refluxed at 120 °C for 6 h in a 6 M nitric acid solution, filtered and washed until neutral to obtain carboxylated single-walled carbon nanotubes, and then ultrasonically dispersed in Reserve in water. At the same time, 10 g of boron nitride powder (average particle size 15 μm) was dispersed in absolute ethanol with high-speed stirring, 2 g of KH550 coupling agent was added dropwise during stirring, stirred for 6 hours, and then heated to 70°C for 30 minutes under reflux. Filter and wash excess coupling agent to obtain amino-functionalized boron nitride. Next, disperse the amino-functionalized boron nitride in water, add carboxylated single-wall carbon nanotube dispersion liquid during the stirring process, mix and stir for 1 hour, filter and wash, and vacuum-dry at 60°C for 4 hours to obtain single-wall carbon nanotube-wrapped boron nitride Composite powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com