Product with coating and preparation method thereof

A technology for products and coatings, which is applied in the field of products with hydrophobic and wear-resistant coatings and its preparation, and can solve problems such as lack of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1. Preparation of coating solution for waterproof surface: 5g of nonafluorohexyl-trichlorosilane, 1g of water and 2g of ethyltriethoxysilane were added to 100g of ethanol, and the resulting mixture was stirred for 30 minutes before use minute. The polymeric fabric was treated with the following steps: (1) ultrasonication for 3 minutes in two successive water baths; (2) dry cleaning of both sides of the fabric at room temperature; (3) rinsing. The polymer fabric was then immersed in the silane solution for 2 hours at 20°C. Fabrics can be sonicated in ethanol for more than 5 min to remove unreacted compounds. Finally, the above fabric was dried at 30°C for 10 minutes. The contact angle of the surface after treatment is 14°, while the rolling angle in the initial state is 10°, which is less than 5° after treatment.

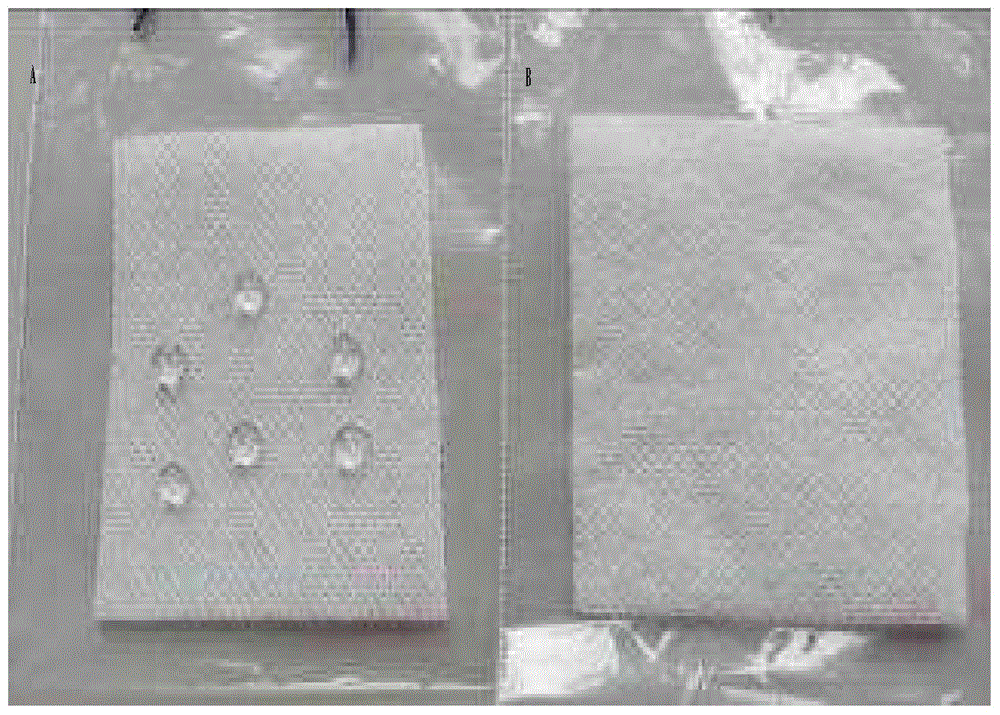

[0042] figure 2 The water repellency and non-stickiness of the above fabrics are illustrated. figure 2 The sample shown in B is a surface-treat...

Embodiment 2

[0043] Embodiment 2. The preparation of the coating liquid of waterproof surface: will 2 g of heptadecafluorooctyl-trimethoxysilane, 0.5 g of water, with 1g Tetrapropyl orthosilicate was added to 100 g of ethanol, and the resulting mixture was stirred for 30 minutes before use. The polymeric fabric was treated with the following steps: (1) ultrasonication for 3 minutes in two successive water baths; (2) dry cleaning of both sides of the fabric at room temperature; (3) rinsing. The polymer fabric was then immersed in the silane solution for 2 hours at 20°C. Fabrics can be sonicated in ethanol for more than 5 min to remove unreacted compounds. Finally, the above fabric was dried at 30°C for 10 minutes. The contact angle of the treated surface is more than 15°, while the rolling angle in the initial state is less than 10°, and the rolling angle of the treated surface is less than 5°.

Embodiment 3

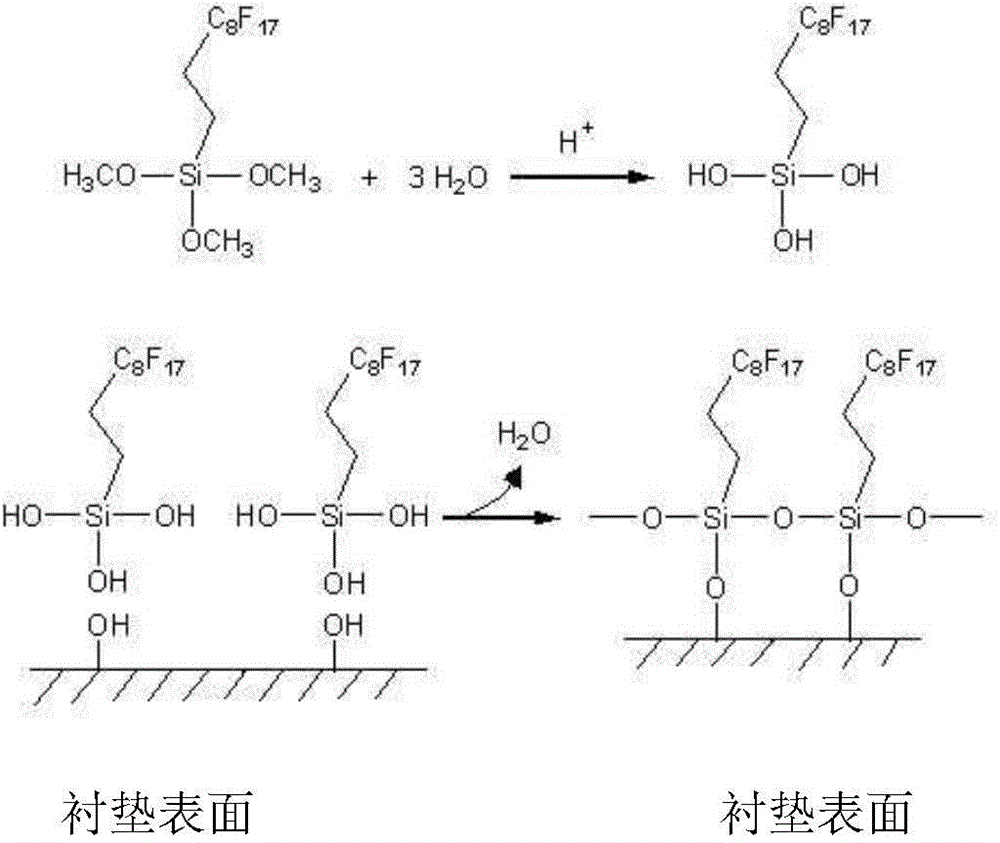

[0044] Example 3. The coating liquid used in Example 2 was sprayed onto the inner surface of the mold at room temperature; by thermal compression, a low roughness of about 50 nm to 1 μm was produced on the untreated pad surface. Then, immerse the pad in hot water at 40°C-100°C. Then put the liner body into the mold, and carry out the thermal compression process at 100°C for 3 minutes. Further modification was performed to lower the critical surface tension by incorporating a low surface energy fluorosilane with reactive end groups, fluoroalkyltrimethoxysilane, onto the surface. The hydrolyzed fluoroalkyltrimethoxysilane coating on the pad surface produced a superhydrophobic film with a contact angle greater than 150. The body contact angle of the liner before treatment was about 100°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com