Processing liquid ejection device of wire electrical discharge machine

A technology of wire electric discharge machine and machining fluid, which is applied to electric machining equipment, accessory devices, metal processing equipment, etc., and can solve problems such as interference between metal wires and nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

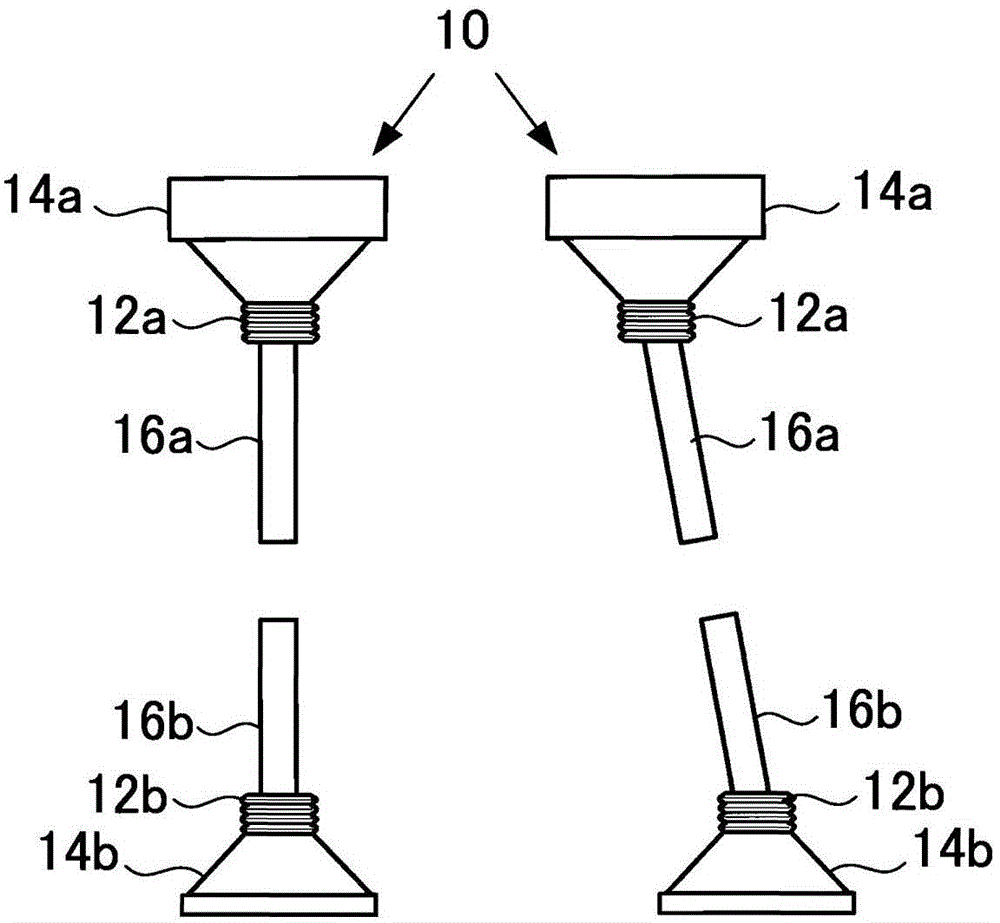

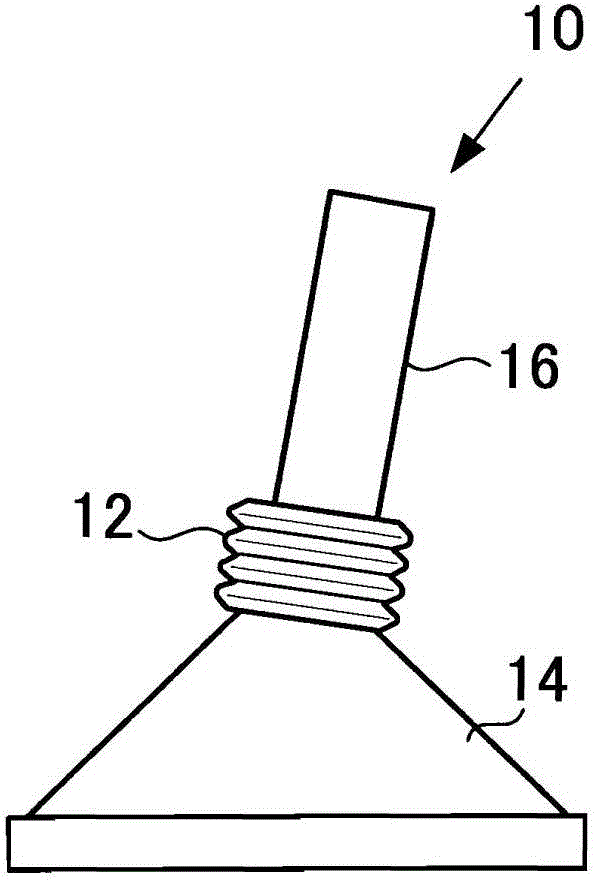

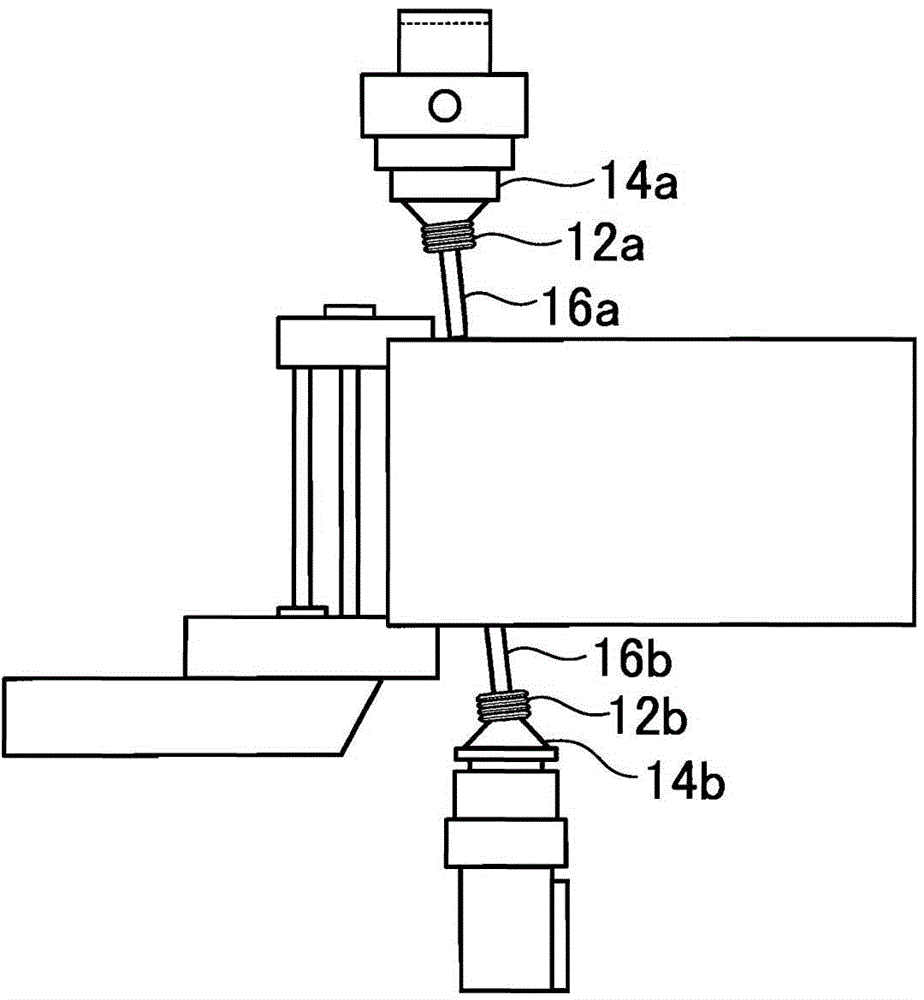

[0031] FIG. 1 is a diagram showing the shape of a nozzle according to the present embodiment, Figure 1A is the overall graph, Figure 1B It is an enlarged view of the vicinity of the bellows. In the figure, reference numeral 10 is a nozzle, and as components constituting the nozzle 10, reference numeral 14a is an upper holding portion, reference numeral 14b is a lower holding portion, reference numeral 16a is an upper machining fluid ejection portion, and reference numeral 14a is an upper holding portion. 16b is a lower machining fluid discharge part. Each holding portion 14 has a conical shape, and each machining fluid discharge portion 16 has a cylindrical shape. In addition, in terms of material, each holding portion 14 and each machining fluid discharge portion 16 are formed of ceramics or resin, but they may also be formed of metal.

[0032] In addition, reference numerals 12 a and 12 b denote rubber bellows that connect the respective holding portions 14 and the mach...

no. 2 approach

[0037] image 3 It is a figure showing the shape of the machining fluid discharge part of this embodiment. The difference from the first embodiment is that, instead of the bellows 12 of the first embodiment, a metal spherical part 18 is provided at the end of the machining fluid discharge part 16 as the angle changing member, and a metal spherical part 18 is provided at the end of the holding part 14. A bearing portion 19 is provided, and the spherical portion 18 is fitted into the bearing portion 19 . Both the spherical body portion 18 and the bearing portion 19 in this embodiment are formed of metal.

[0038] In this embodiment, compared with the structure of the bellows 12 of the first embodiment, the machining fluid ejection part 16 can be more smoothly moved in the U-axis direction by the spherical bearing structure composed of the spherical part 18 and the bearing part 19. , Tilting in the direction of the V axis.

[0039] In addition, both the structure of the bellow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com