A double-head cutting machine for electronic components

A technology of electronic components and cutting machine, which is applied in the field of double-head cutting machines for electronic components processing, and can solve the problems of slow cutting speed, inaccurate cutting and slow processing speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

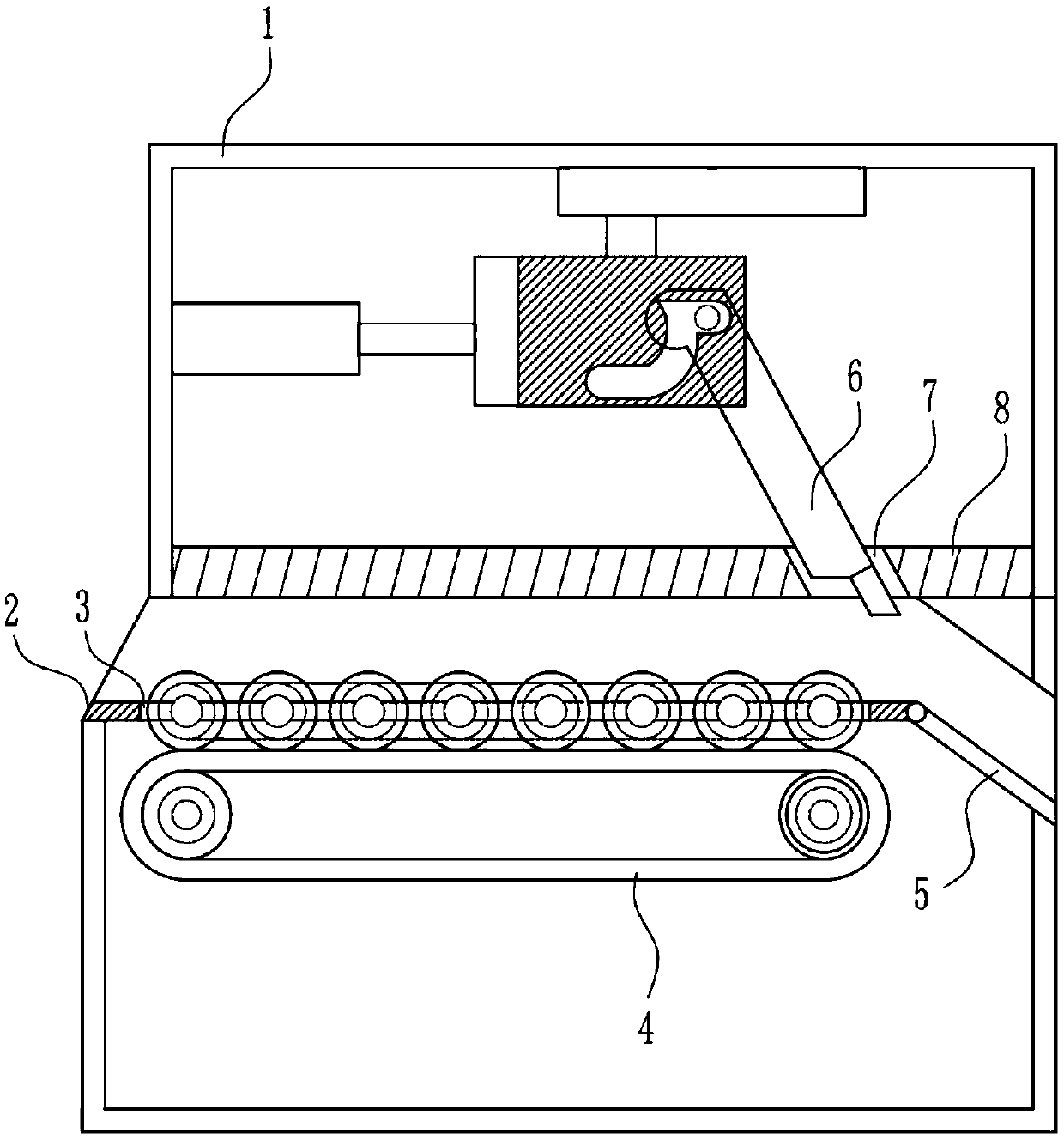

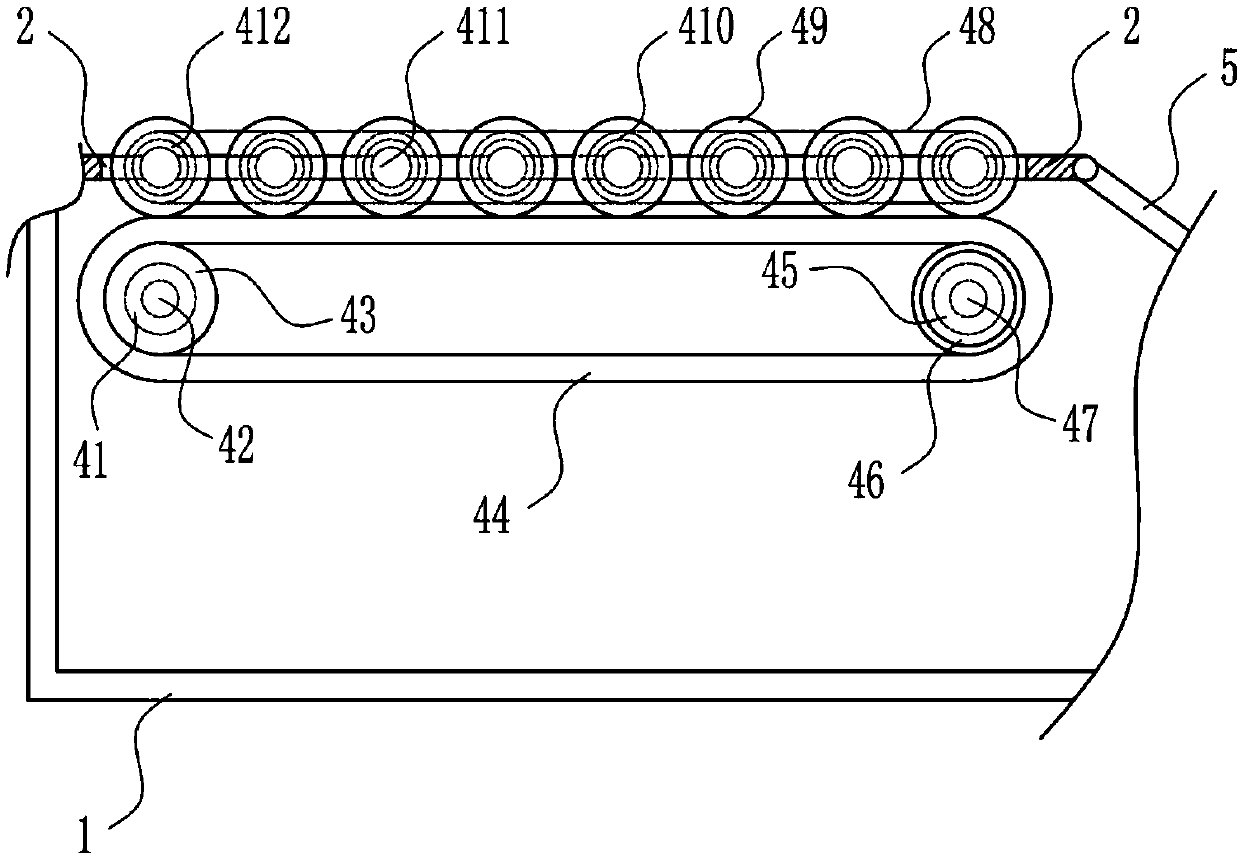

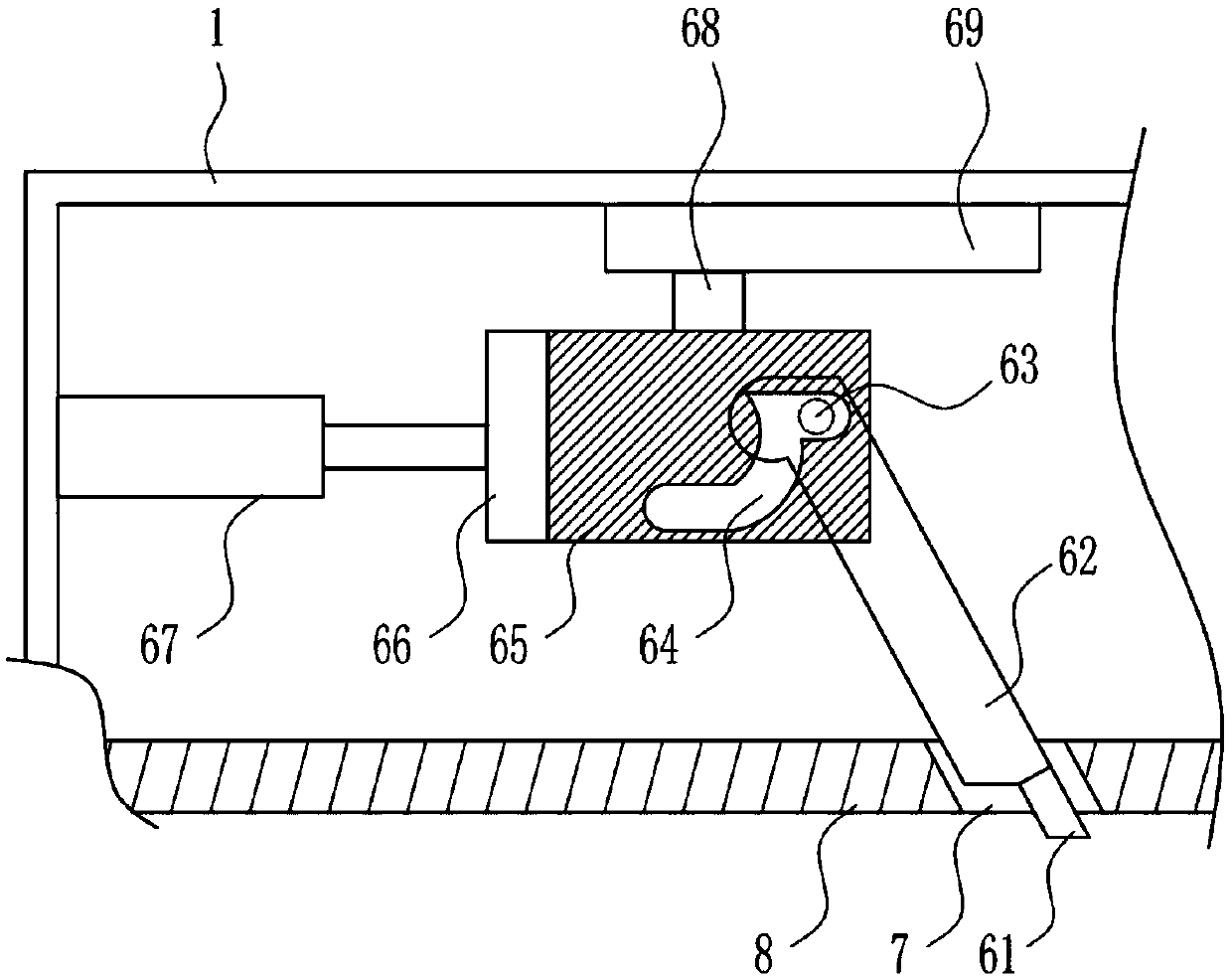

[0033] A double-head cutting machine for processing electronic components, such as Figure 1-7 As shown, it includes a working box 1, a conveying trough 2, a conveying device 4, an outlet trough 5, a cutting device 6, and a horizontal plate 8. The working box 1 is connected with a horizontal plate 8 front and back, and a conveying trough is arranged on the left side of the bottom of the horizontal plate 8. 2. The transfer slot 2 communicates with the left wall of the working box 1. The bottom of the transfer slot 2 is provided with a bar-shaped hole 3. The right side of the horizontal plate 8 is provided with an export slot 5. The export slot 5 communicates with the right wall of the working box 1. The horizontal plate 8 is set on the right side. The top of the working box 1 is provided with a cutting device 6, the cutting device 6 passes through the guiding hole 7, and the lower part of the working box 1 is provided with a conveying device 4, and the conveying device 4 is conn...

Embodiment 2

[0035] A double-head cutting machine for processing electronic components, such as Figure 1-7 As shown, it includes a working box 1, a conveying trough 2, a conveying device 4, an outlet trough 5, a cutting device 6, and a horizontal plate 8. The working box 1 is connected with a horizontal plate 8 front and back, and a conveying trough is arranged on the left side of the bottom of the horizontal plate 8. 2. The transfer slot 2 communicates with the left wall of the working box 1. The bottom of the transfer slot 2 is provided with a bar-shaped hole 3. The right side of the horizontal plate 8 is provided with an export slot 5. The export slot 5 communicates with the right wall of the working box 1. The horizontal plate 8 is set on the right side. The top of the working box 1 is provided with a cutting device 6, the cutting device 6 passes through the guiding hole 7, and the lower part of the working box 1 is provided with a conveying device 4, and the conveying device 4 is conn...

Embodiment 3

[0038] A double-head cutting machine for processing electronic components, such as Figure 1-7 As shown, it includes a working box 1, a conveying trough 2, a conveying device 4, an outlet trough 5, a cutting device 6, and a horizontal plate 8. The working box 1 is connected with a horizontal plate 8 front and back, and a conveying trough is arranged on the left side of the bottom of the horizontal plate 8. 2. The transfer slot 2 communicates with the left wall of the working box 1. The bottom of the transfer slot 2 is provided with a bar-shaped hole 3. The right side of the horizontal plate 8 is provided with an export slot 5. The export slot 5 communicates with the right wall of the working box 1. The horizontal plate 8 is set on the right side. The top of the working box 1 is provided with a cutting device 6, the cutting device 6 passes through the guiding hole 7, and the lower part of the working box 1 is provided with a conveying device 4, and the conveying device 4 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com