Double-clutch eccentric oil through processing method and corresponding double-clutch blank

A dual-clutch, processing method technology, applied to clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve the problems that affect the machining accuracy and efficiency of eccentric oil holes, and are easy to deflect or break, so as to avoid tool change The effect of fast frequency, avoiding serious out-of-tolerance, and avoiding processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

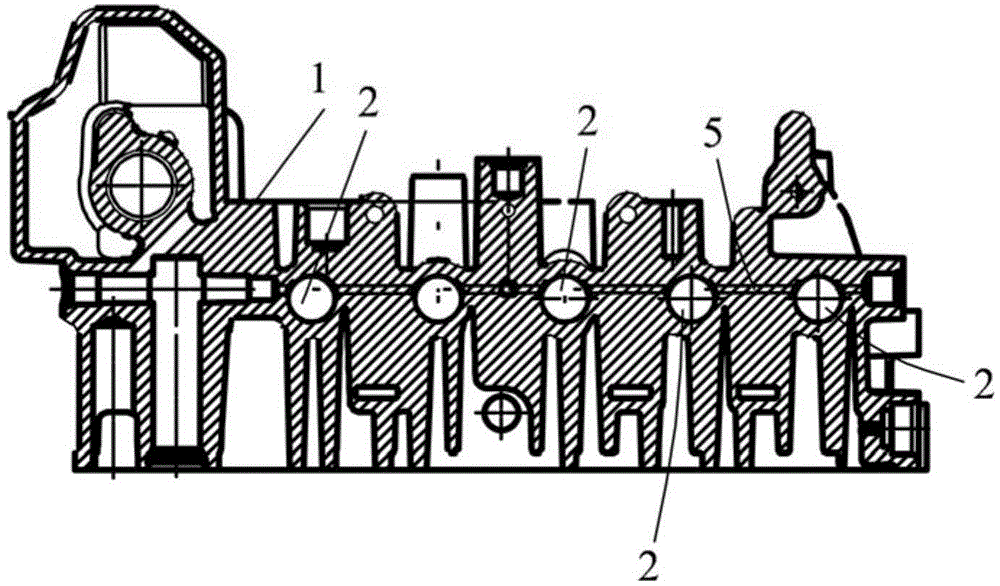

[0032] figure 1 Shown is a dual-clutch blank 1 in the prior art, which is a dual-clutch for automobiles. A plurality of electromagnetic valve holes 2 are arranged in parallel on the dual-clutch blank 1. According to design requirements, an eccentric oil hole 5 needs to be processed Intersect with all solenoid valve holes 2.

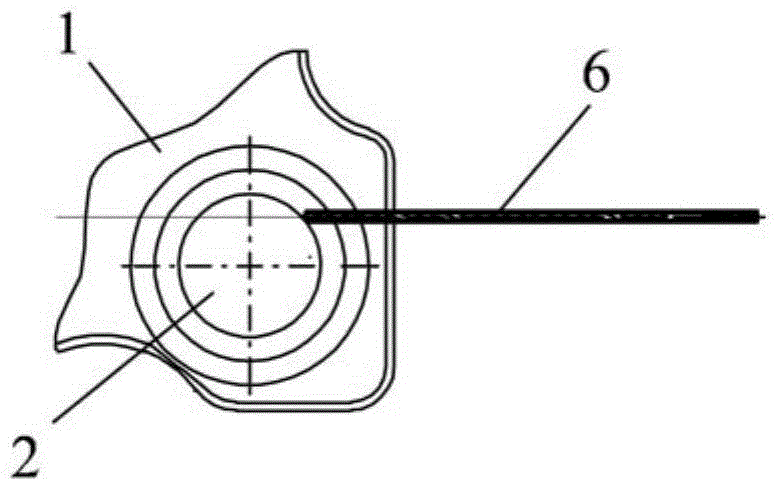

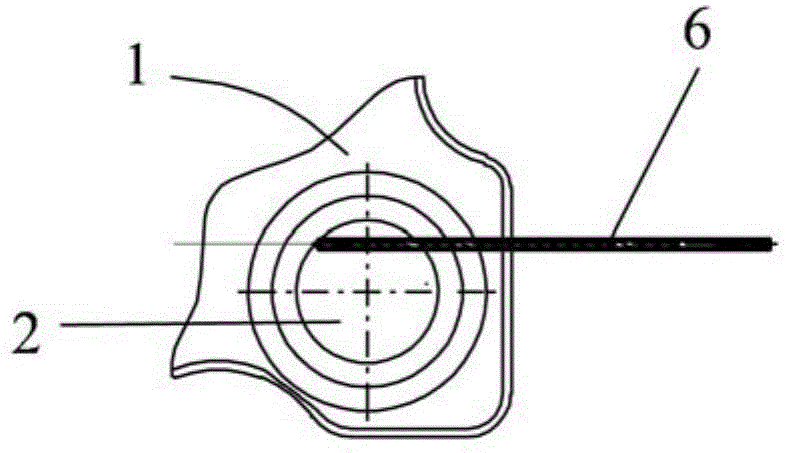

[0033] Such as figure 2 and image 3 As shown, the existing processing method is to directly drill holes with a drill bit 6 on the dual-clutch blank 1. When the other side of 2 passes through the solenoid valve hole 2, only one side of the drill bit 6 is in contact with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com