Pesticide nano-solid dispersion and preparation method thereof

A technology for solid dispersions and pesticides, applied in the field of pesticides, can solve the problems of agglomeration, flocculation, and sedimentation that cannot be effectively overcome, difficulty in exerting ideal application effects, and poor stability of liquid formulations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

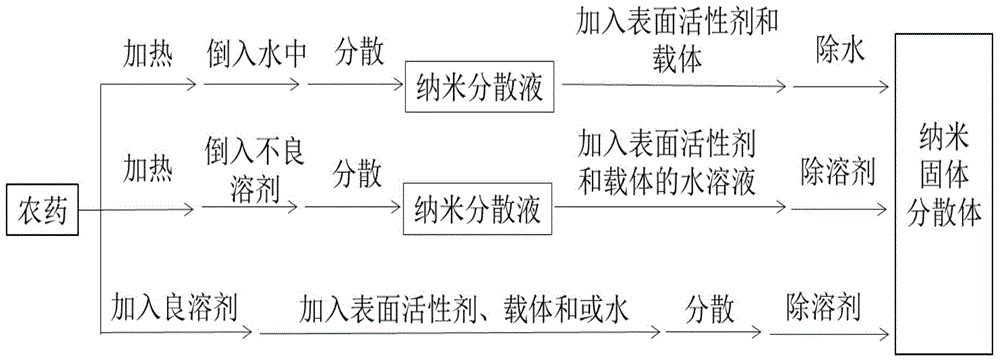

Image

Examples

Embodiment 1

[0079] Embodiment 1: Preparation of pesticide nano solid dispersion of the present invention

[0080] The implementation steps of this embodiment are as follows:

[0081] A. Preparation of Nanodispersion

[0082] Heat 0.001 parts by weight of lambda-cyhalothrin insecticide to about 10°C higher than its melting point of 49.2°C, pour it into water, and then use a high-speed shear emulsifier sold under the trade name C25 by ATS Company at a speed of 10,000rpm Under shearing for 20min, the lambda-cyhalothrin is uniformly dispersed in water, then cooled to normal temperature to obtain a dispersion of lambda-cyhalothrin solid nanoparticles; then

[0083] B. Preparation of Nano Solid Dispersion

[0084] Add 0.099 parts by weight of sodium dodecylsulfonate anionic surfactant and 99.9 parts by weight of urea to the efficient cyhalothrin solid nanoparticle dispersion obtained in step A, stir evenly with a rotating speed of 1000rpm, and then use The drying equipment sold by the compan...

Embodiment 2

[0086] Embodiment 2: Preparation of pesticide nano solid dispersion of the present invention

[0087] The implementation steps of this embodiment are as follows:

[0088] A. Preparation of Nanodispersion

[0089] Heat 10 parts by weight of nitenpyram insecticide to about 10°C higher than its melting point of 83°C, pour it into water, and then use a high-speed shear emulsifier sold under the trade name C25 by ATS Company to shear at a speed of 20,000rpm. Cut for 20 minutes, uniformly disperse nitenpyram in water, and cool to normal temperature to obtain a nitenpyram solid nanoparticle dispersion; then

[0090] B. Preparation of Nano Solid Dispersion

[0091] Add 50 parts by weight of monododecyl ether phosphate salt anionic surfactant and 40 parts by weight of sodium sulfate water-soluble carrier to the nitenpyram solid nanoparticle dispersion liquid obtained in step A, stir evenly with rotating speed 1800rpm, and then use The rotary evaporator sold under the trade name R-21...

Embodiment 3

[0093] Embodiment 3: Preparation of pesticide nano solid dispersion of the present invention

[0094] The implementation steps of this embodiment are as follows:

[0095] A. Preparation of Nanodispersion

[0096] 30 parts by weight of spinosad insecticides are heated to about 10°C above its melting point of 84°C, poured into water, and then homogenized under the condition of a pressure of 600bar using a high-pressure homogenizer sold by ATS Company under the trade name AH-100D. After 20 minutes, the spinosyn was uniformly dispersed in water, and cooled to normal temperature to obtain a spinosad solid nanoparticle dispersion; then

[0097] B. Preparation of Nano Solid Dispersion

[0098] Add 0.03 parts by weight of octyl ether phosphate anionic surfactant and 69.97 parts by weight of magnesium sulfate water-soluble carrier to the spinosad solid nanoparticle dispersion obtained in step A, stir evenly with a rotating speed of 1200rpm, and then use the The equipment sold under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com