Battery anode/cathode cover board production method and battery anode/cathode cover board

A production method and negative electrode cover technology, which is applied in the production field of rotary friction welding products, can solve the problems such as the overall structure of the positive/negative electrode cover plate of the battery is not firm, and achieve the effect of increasing the service life and improving the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

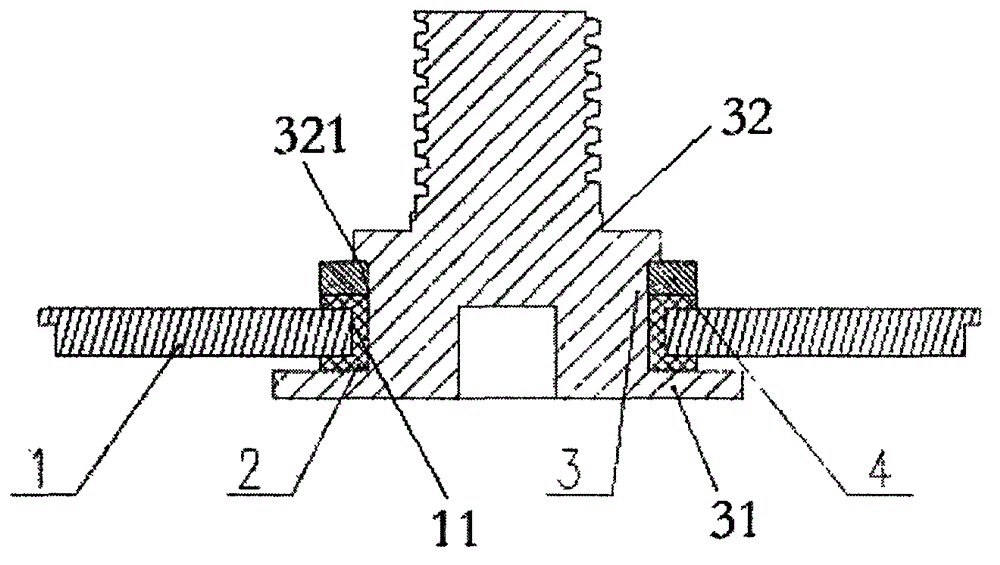

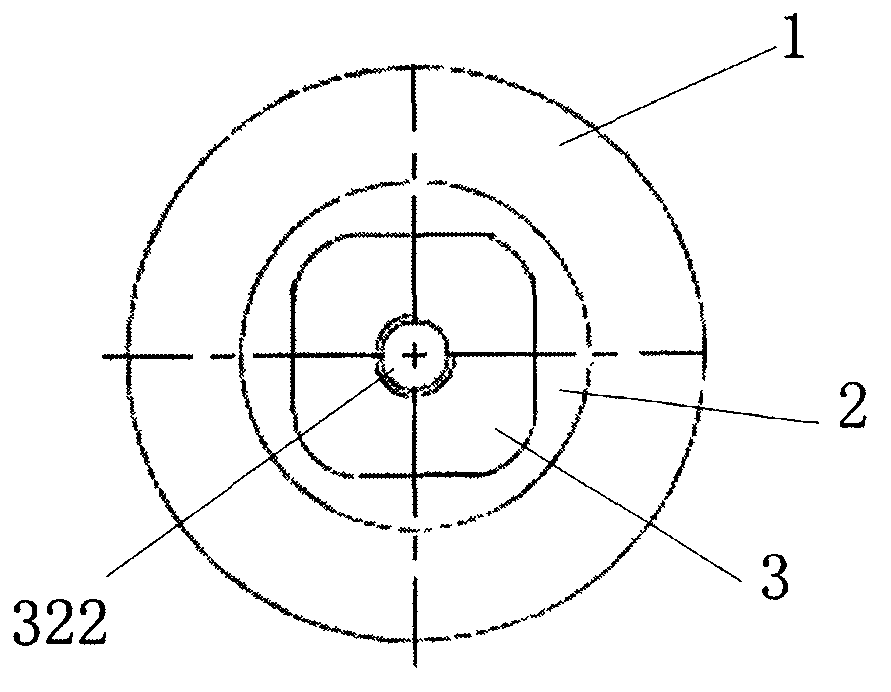

[0033] In this embodiment, a production method of a battery positive / negative cover plate comprises the following steps:

[0034] S1: Use plate-shaped aluminum parts, and process through holes in the aluminum parts, the aluminum parts are 1060 aluminum;

[0035] S2: An insulating ring is clamped in the through hole, the insulating ring has a mounting hole, the upper surface of the insulating ring is attached to the upper surface of the aluminum part, and the lower surface of the insulating ring is attached to the lower surface of the aluminum part; insulation The ring is made of PTFE;

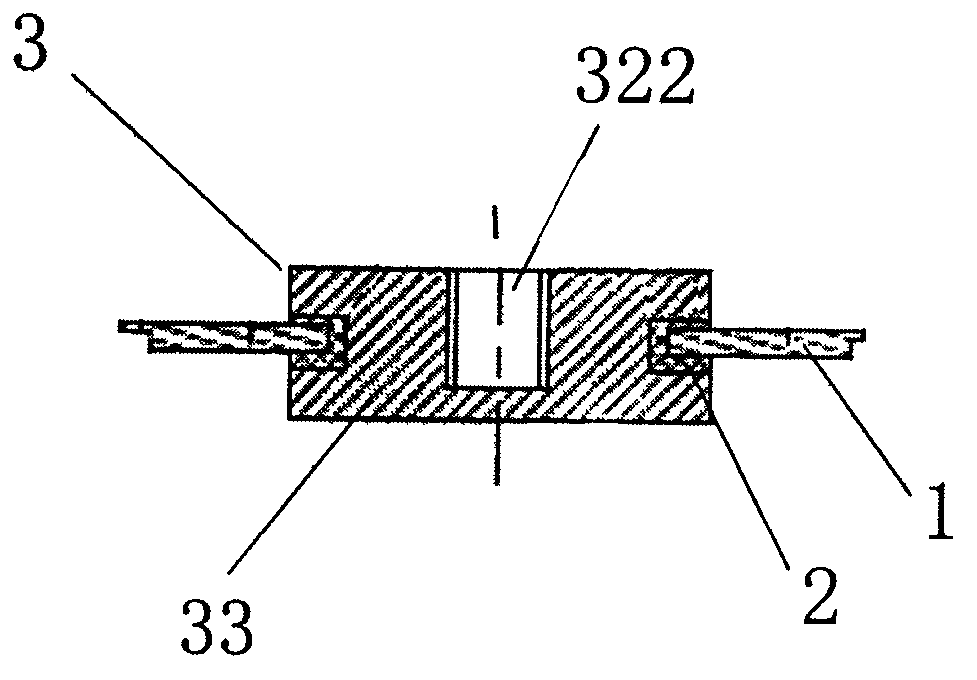

[0036] S3: Two copper parts are used, the copper part has a cylindrical boss 0.5mm larger than the inner diameter of the mounting hole and a cylindrical base 342 with a diameter larger than the diameter of the cylindrical boss 341, the cylindrical boss 341 and the cylindrical base 342 is set coaxially, the surface roughness of the top surface of the cylindrical boss 341 is Ra1.6, and the coppe...

Embodiment 2

[0041] In this embodiment, a production method of a battery positive / negative cover plate comprises the following steps:

[0042] S1: Use plate-shaped aluminum parts, and process through holes in the aluminum parts, the aluminum parts are 3003 aluminum;

[0043]S2: An insulating ring is clamped in the through hole, the insulating ring has a mounting hole, the upper surface of the insulating ring is attached to the upper surface of the aluminum part, and the lower surface of the insulating ring is attached to the lower surface of the aluminum part; insulation The ring is made of PTFE;

[0044] S3: Two copper parts are used. The copper part has a cylindrical boss 341 with a diameter larger than the diameter of the mounting hole 341 and a cylindrical base 342 with a diameter larger than the diameter of the cylindrical boss 341. The cylindrical boss 341 and the cylindrical The base 342 is coaxially arranged, the surface roughness of the top surface of the cylindrical boss 341 is ...

Embodiment 3

[0049] In this embodiment, a production method of a battery positive / negative cover plate comprises the following steps:

[0050] S1: Use plate-shaped aluminum parts, and process through holes in the aluminum parts, the aluminum parts are 3003 aluminum;

[0051] S2: An insulating ring is clamped in the through hole, the insulating ring has a mounting hole, the upper surface of the insulating ring is attached to the upper surface of the aluminum part, and the lower surface of the insulating ring is attached to the lower surface of the aluminum part; insulation The ring is made of PTFE;

[0052] S3: two copper parts are used, the copper part has a cylindrical boss 341 with a diameter larger than the inner diameter of the mounting hole 341 and a cylindrical base 342 with a diameter larger than the diameter of the cylindrical boss 341, the cylindrical boss 341 and the cylindrical base 342 is set coaxially, the surface roughness of the top surface of the cylindrical boss 341 is Ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com