High-power crimping type IGBT encapsulation module fixture

A packaged module, crimping technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of limited tensile force of ordinary metal insulating rods, unsatisfactory heat dissipation effect of ordinary radiators, and difficulty in applying force to the overall fixture. and other problems, to achieve the best anti-oxidation and anti-corrosion performance, easy production and assembly and disassembly and maintenance, and low thermal expansion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to better understand the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings and examples.

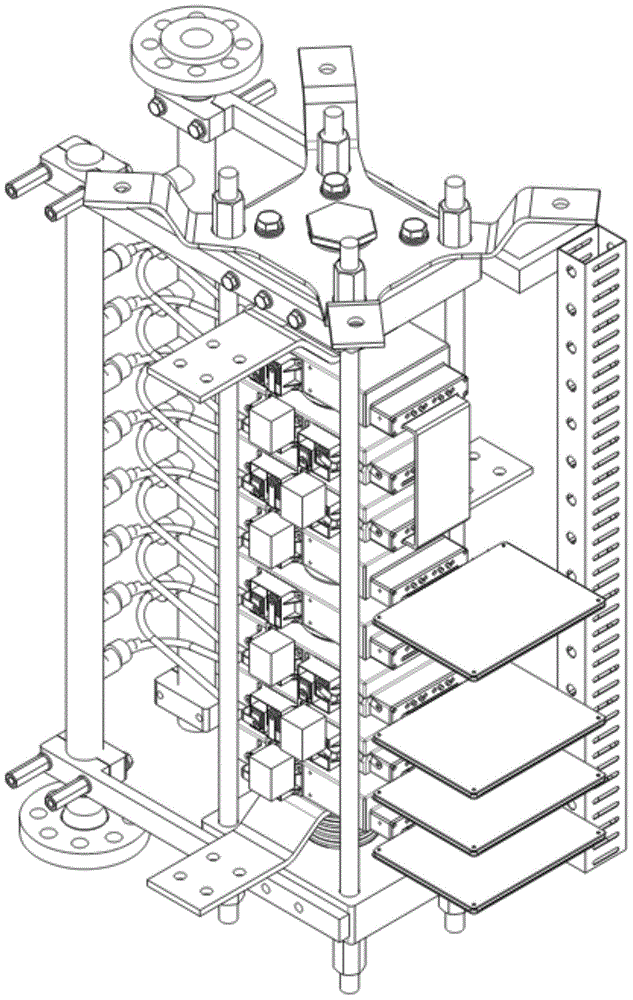

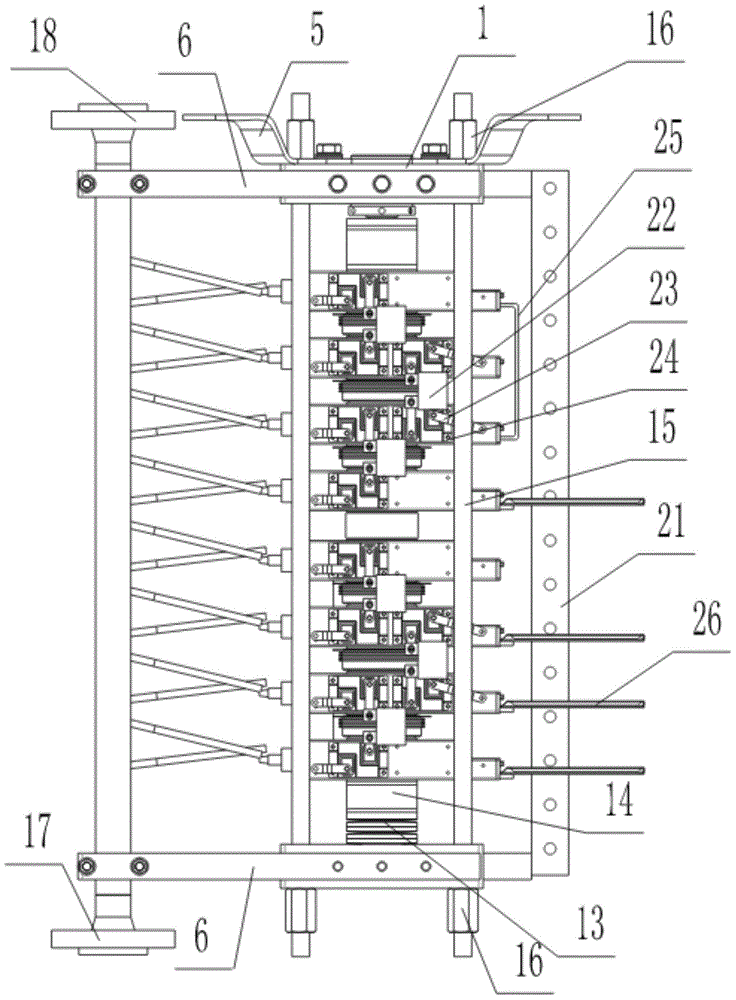

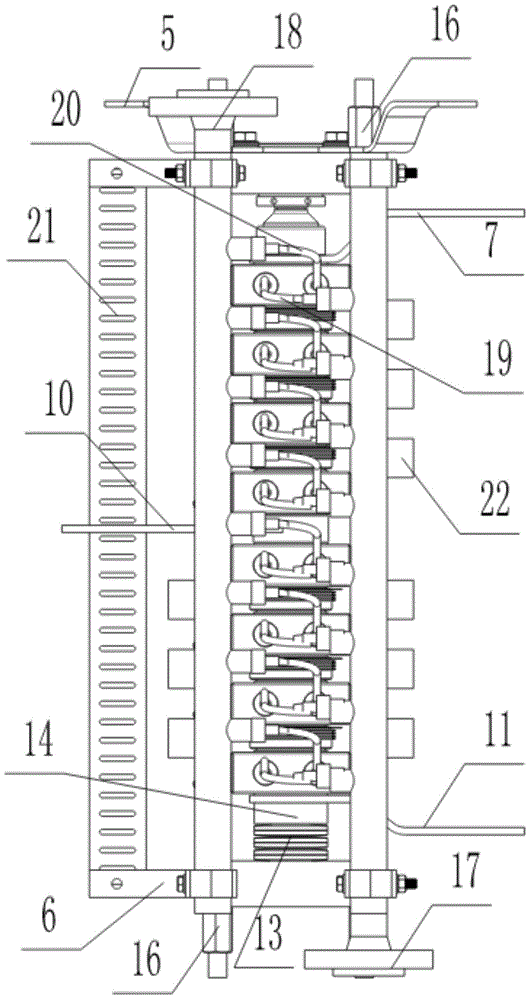

[0047] The present invention provides a high-power crimping type IGBT packaging module fixture, its three-dimensional structure diagram is as follows figure 1 As shown, it includes: upper fixture flange set, upper lead-out row 7, upper water-cooling heat dissipation set, middle lead-out row fixing block, lower water-cooling heat dissipation set, lower end lead-out row 11, lower load-bearing flange set, high-performance vertical Straight insulating support rod, radiator waterway assembly, wire channel assembly, capacitor assembly, damping resistance assembly, short circuit board 25, drive board 26;

[0048] The upper clamp set is longitudinally arranged on the upper surface of the upper lead-out row 7; the lower surface of the upper lead-out row 7 is longitudinally connected to the upper wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com