Catalyst performance evaluation device and catalyst performance evaluation method

An evaluation device and evaluation method technology, which is applied in the direction of chemical analysis using catalysis, can solve the problems of inaccurate evaluation results of catalyst performance, large changes in the relative amount of catalyst and reactants, etc., to ensure contact, sufficient activity, and accurate results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments of the present invention. Combine with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

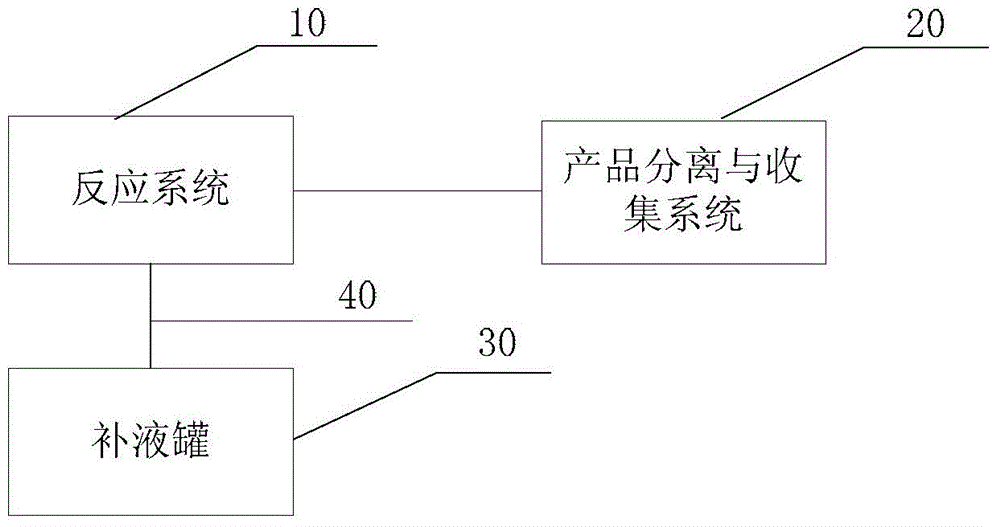

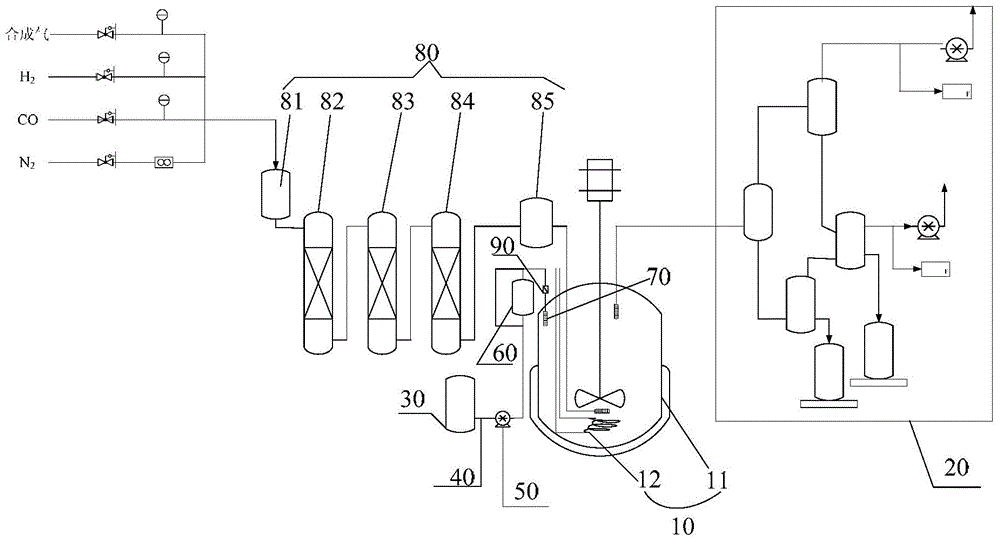

[0029] As introduced in the background technology section, there is a problem in the prior art that it is difficult to effectively evaluate the desired catalyst when both the reactants and the products are gases. In order to solve this problem, in a typical embodiment of the present invention, a catalyst performance evaluation device is provided. Such as figure 1 As shown, this catalyst performance evaluation device includes a reaction system 10 and a product separation and collection system 20, wherein the product separation and collection system 20 is located downstream of the reaction system 10, and further the catalyst performance evalu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com