External-mixing polishing gun for glass ware

A glassware and gun body technology, applied in the direction of burners, burners, gas fuel burners, etc., can solve problems such as insufficient gas combustion, unsafe polishing guns, and oxygen bubbles in products, and achieve stable flames and good safety , the effect of high combustion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

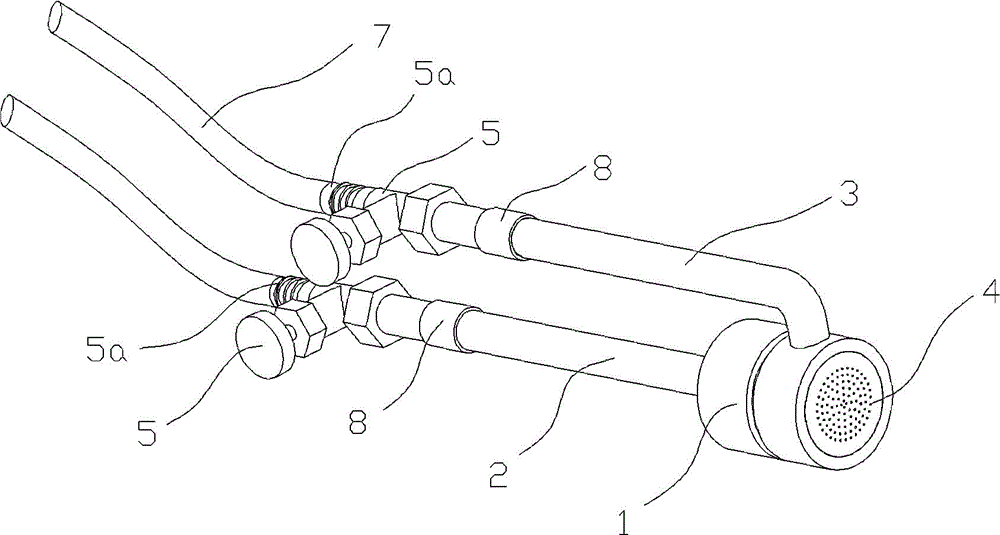

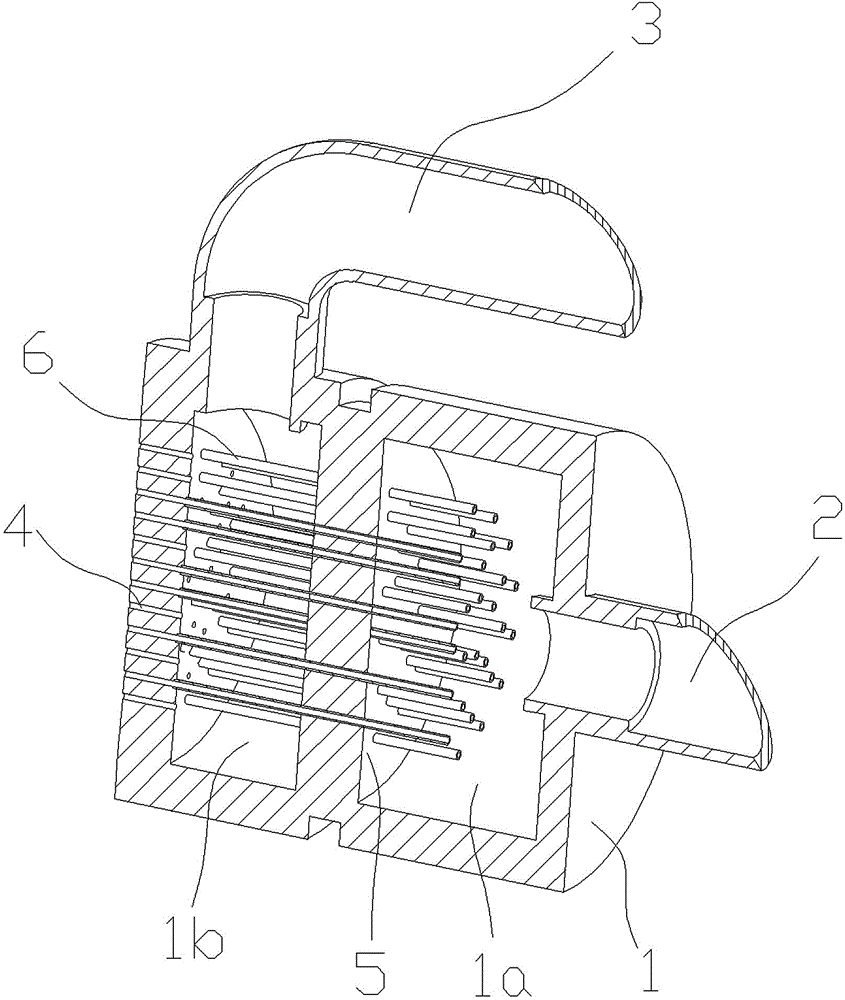

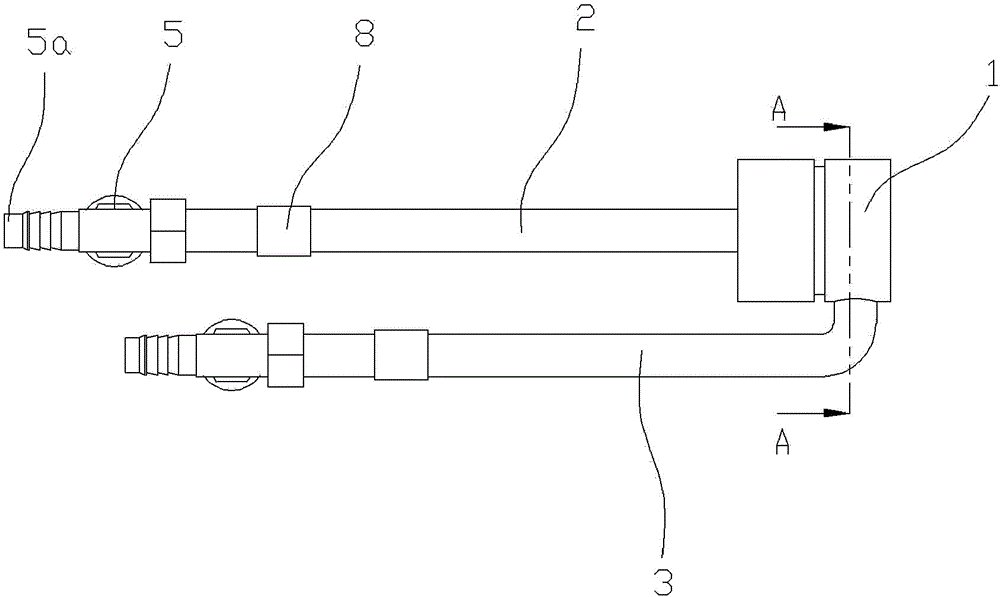

[0015] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a kind of glassware external mixing polishing gun provided by the present invention comprises the gun body 1 of inner cavity, and the gun body 1 is a cylinder, and a plurality of circular air outlet holes 4 are evenly distributed on an end face of the gun body 1, A main gas pipe 2 is provided on the other end face of the gun body 1, and a combustion-supporting gas pipe 3 is provided on the side of the gun body 1, and the main gas pipe 2 and the combustion-supporting gas pipe 3 are all connected with the inside of the gun body 1. The cavities are matched and communicated, and it is characterized in that: a partition 5 is arranged in the internal cavity of the gun body 1, and the partition 5 divides the internal cavity of the gun body 1 into two relatively closed first cavities 1a and The second cavity 1b is provided with an air guide tube 6 on the end surface of the gun body 1 provided with the air outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com