Side-in display module and display device

A display module and side-entry technology, which is applied to lighting devices, fixed lighting devices, components of lighting devices, etc., can solve problems such as complicated assembly procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

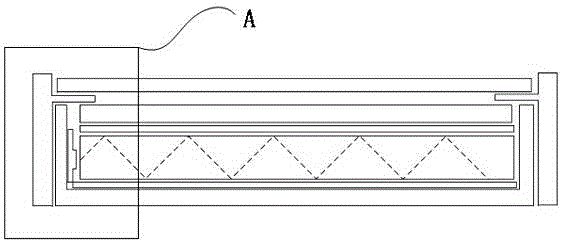

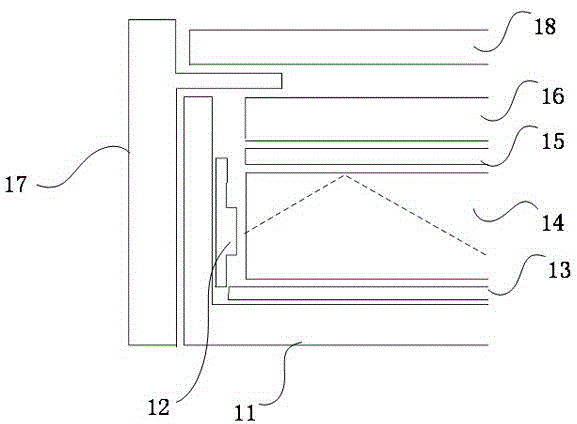

[0023] Such as image 3 and Figure 4 As shown, the present invention provides a side-entry display module, including a backplane 21, an excitation light source 22, a reflector 23, an optical film 25, a plastic frame 26 and a liquid crystal panel 27, and also includes: a light guide plate 241, a coating The refraction layer 242 disposed on the light guide plate 241 , and the quantum dot layer 243 coated on the refraction layer 242 . In this embodiment, the back plate 21 is a rigid component used to support the structure of the entire side-entry display module. There is an upward folded edge around the back plate 21, which is used to fix the plastic frame and excite The light source 22 forms a limited space for accommodating the reflective sheet 23, the light guide plate 241 and the like.

[0024] The light incident surface of the light guide plate 241 is set relative to the excitation light source 22, and is used to receive the light emitted by the excitation light source. A...

Embodiment 2

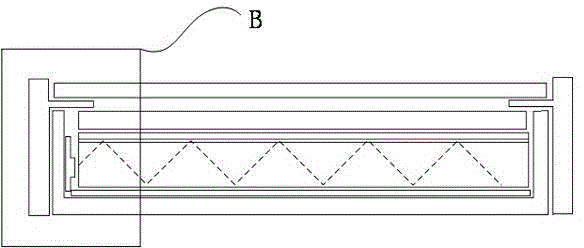

[0034] Such as Figure 5 and Figure 6 As shown, the present invention provides a side-entry display module, which includes an excitation light source 31, an optical film 33, a plastic frame 34 and a liquid crystal panel 35, and also includes a light guide plate 321 and a refraction layer coated on the light guide plate 321. 322 . The quantum dot layer 323 coated on the refraction layer 322 , preferably, further includes a reflective layer 324 disposed on the other side of the light guide plate opposite to the refraction layer 322 . In this embodiment, the light guide plate 321 is a rigid component used to support the structure of the entire side-entry display module. The limit of panel 35.

[0035] The light incident surface of the light guide plate 321 is set relative to the excitation light source 31, and is used to receive the light emitted by the excitation light source. A reflective layer 324 is arranged under the light guide plate 321. The light is reflected to the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com