Wire rod for low-carbon, high-strength, high-toughness steel strand and its production process

A high-toughness steel and production process technology, applied in the production field of wire rods for steel strands, to achieve the effects of ensuring stability, improving tensile strength, and increasing sorbite content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: In summer, the summer process is adopted for the specification Φ11.0mm. The operation process of this steel grade in the present invention is as follows:

[0024] 1) The rolling temperature is controlled at 1040-1060 °C, the temperature of the finishing rolling and the cutting and sizing mill is controlled from 900-930 °C, and the spinning temperature is controlled at 930-960 °C;

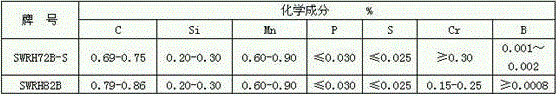

[0025] 2) Φ11.0mm production batch number is X5140811229 SWRH72B-S composition and cooling process are shown in the following table:

[0026] Chemical composition content:

[0027]

[0028] Controlled cooling process:

[0029]

[0030] Product performance: The mechanical properties of the final product Φ11.0mm SWRH72B-S are as follows:

[0031]

Embodiment 2

[0032] Embodiment 2: In winter, the low-carbon high-strength high-toughness SWRH72B-S production process includes the following steps:

[0033] 1) The starting rolling temperature is controlled at 1040-1060°C, the temperature of the finishing rolling and cutting and sizing mills is controlled from 900-930°C, and the spinning temperature is controlled at 930-960°C;

[0034] 2) The composition and cooling process of SWRH72B-S with Φ8.0mm production batch number: X6141201729 are shown in the following table:

[0035] Chemical composition content:

[0036]

[0037] Controlled cooling process:

[0038]

[0039] Product performance: The mechanical properties of Φ8.0mm SWRH72B-S are shown in the table:

[0040]

[0041] The situation cited in the present invention shows that the product has reached the technical index negotiated with the user. After using this composition system, while ensuring that the wire rod reaches the tensile strength of SWRH82B, the elongation and a...

Embodiment 3

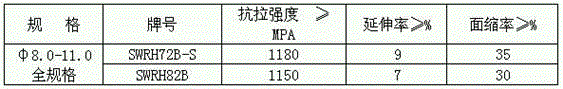

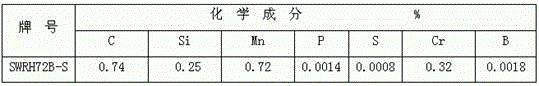

[0043] Embodiment 3: the SWRH72B-S type wire rod produced by the present invention is compared with the existing SWRH82B type wire rod on the market, and the results obtained are shown in the table below:

[0044]

[0045] The corresponding mechanical properties of the wire rod are shown in the table below:

[0046]

[0047] The properties of steel strands processed from wire rods are shown in the table below:

[0048]

[0049] It can be concluded that the newly developed 72B-S replaces the 82B wire rod, reduces the composition of the billet by 0.10%, and keeps the alloy composition such as Si and Mn unchanged, and improves the toughness of the wire rod by reducing the C content, thereby improving the steel strand. The toughness of the wire makes the wire rod and steel strand change from the original method of reducing toughness and increasing strength to improving strength and improving product toughness.

[0050] Due to the adjustment of the composition, the effect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com