Healthy and safe Luzhou-fragrant camellia oil with strong flavor and preparation method thereof

A camellia oil, rich technology, applied in the direction of fat oil/fat refining, fat oil/fat production, fat generation, etc., can solve the problem that the aroma of camellia oil and the content of benzo harmful substances cannot be solved at the same time, and the compounds that cannot form and bring out the aroma of camellia tea. , the disappearance of the unique flavor of camellia oil, etc., to achieve the effect of reasonable and scientific control of temperature and other conditions, stable overall flavor and moderate softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] A method for preparing strong-flavored, healthy and safe Luzhou-fragrant camellia oil, which mainly includes the following process steps:

[0055] one. tea seed kernel

[0056] Drying: take the fresh tea seeds of the year, spread them out and dry them naturally, so that the water content of the tea seeds is controlled at 10-20% by mass;

[0057] Shelling: take off the seed shell of tea seeds to get tea seed kernels;

[0058] Selection and removal of impurities: remove moldy tea seeds; manual selection can be used to remove moldy tea seeds, or machine (color sorter) can be used to remove moldy tea seeds by color sorting, that is, according to the difference in color between moldy tea seeds and fresh tea seeds , using the difference in its optical properties, the moldy tea seeds are automatically separated by the machine; the iron filings or iron pieces that may exist in the tea seed kernels are removed by magnetic adsorption;

[0059] Maturing: Roasting and curing the...

Embodiment 1-7

[0072] By above method, made 1-7 embodiment, the main parameter of each embodiment main step is as shown in table 1, table 2 as follows:

[0073] Table 1 The main parameters of the manufacturing process steps

[0074] Example

Step one ripening: roasting temperature, tea

Kernel Moisture

Step 3, tea dry broken

time

Step 3, dry oil mixing: camellia oil content,

moisture content

One squeeze, two squeezes

Bore temperature

Step 4, activated carbon before filtration

Dosage

Example 1

130°C, 3% by mass

that day

15% by mass, 7% by mass

100℃,100℃

/

Example 2

130°C, 4% by mass

next day

20% by mass, 8% by mass

110℃,110℃

/

Example 3

140°C, 3% by mass

that day

25% by mass, 8.5% by mass

120℃,120℃

/

Example 4

150°C, 4.5% by mass

next day

18% by mass, 9% by mass

130℃,130℃

/

Example 5

150°C, 5% by mass

that day

30% by mass, 10% by m...

Embodiment 6-7

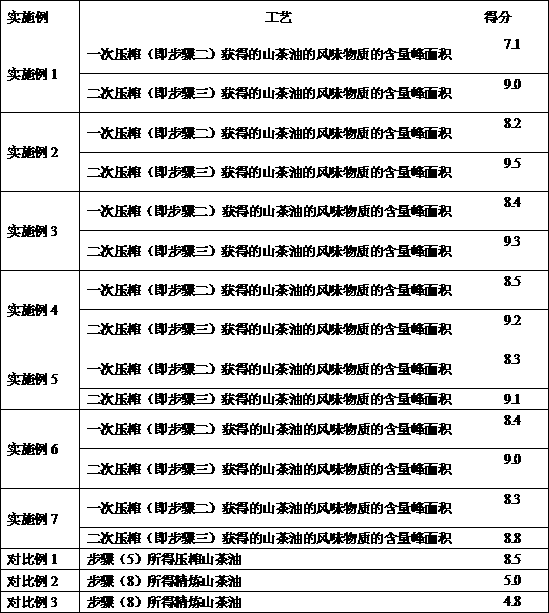

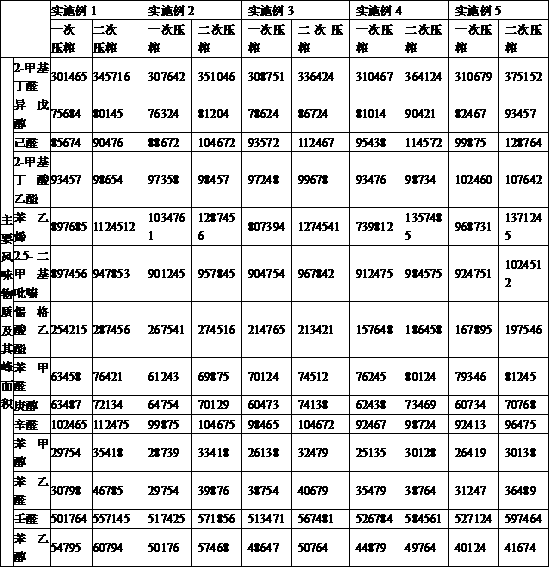

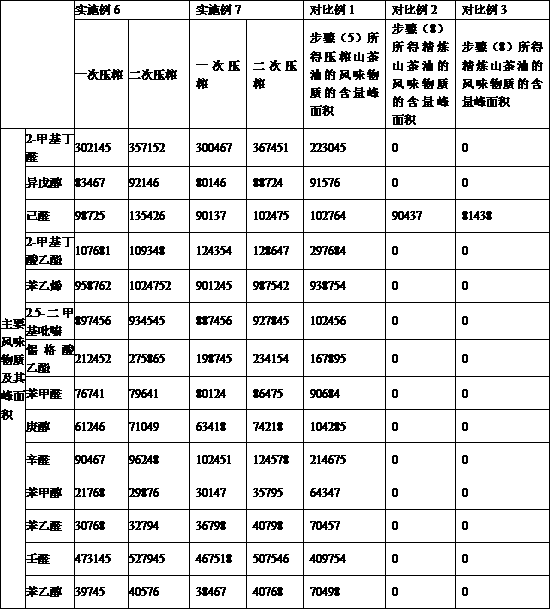

[0136] Table 9 embodiment 6-7, comparative example 1-3 flavor substance detection result

[0137]

[0138] In Table 7 and Table 8, the first pressing refers to the peak area of the content of flavor substances of the camellia oil obtained (ie, step 2), and the second pressing refers to the peak area of the content of the flavor substances of the camellia oil obtained (ie, step 3).

[0139] As can be seen from physical and chemical index detection result table 4, table 5, the camellia oil that the program cooling of the present invention obtains has good fineness, no toxic and side effects, and is safe; as can be seen from odor evaluation result table 6, the camellia oil that the present invention obtains, gives People's feeling is that fragrance is rich and fresh; As can be seen from flavor substance test result table 7, table 8, the camellia oil that the present invention obtains has sweet fragrance or aromatic nonanal, ethyl tigrate, styrene, 2 - Methylbutyraldehyde; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com