Tungsten oxide quantum dot material and preparation method thereof

A technology of tungsten oxide quantum dots and tungsten oxide, which is applied in the field of tungsten oxide quantum dot materials and their liquid phase preparation, tungsten oxide nanomaterials and their preparation, can solve the problems of difficult template removal and inconvenient application, and achieve obvious quantum size effect , easy to operate, uniform particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

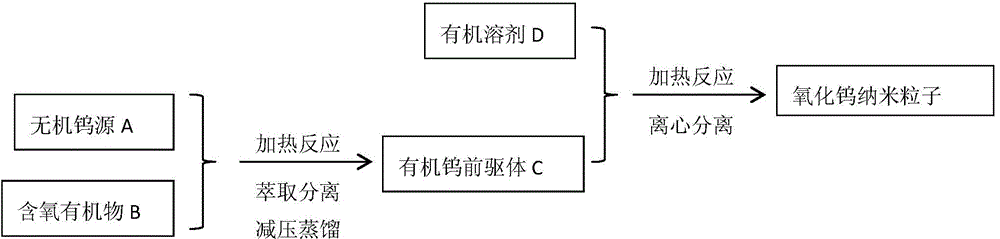

Method used

Image

Examples

Embodiment 1

[0037]Precursor synthesis: Mix 1.6g tungstic acid and 4g phenol in a 100ml single-necked flask, heat to 100 oC , after reacting for 12 hours, cool down at room temperature naturally, add 100ml 5% KOH solution and 50ml petroleum ether successively, wash, extract, separate liquid, repeat this process 3 times, collect the upper layer, 40 oC Distilled under reduced pressure to obtain 0.9 g of organic tungsten precursor with a yield of about 30.0%.

Embodiment 2

[0039] Precursor synthesis: Mix 3.6g tungsten oxychloride and 12g benzaldehyde in a 100ml single-necked flask, heat to 60 oC , after reacting for 10h, cool down at room temperature naturally, and add 50ml 10% Na 2 CO 3 Solution and 100ml petroleum ether, washing, extraction, liquid separation, this process was repeated 3 times, and the upper layer was collected, 40 oC Distilled under reduced pressure to obtain 4.2 g of organic tungsten precursor with a yield of about 62.4%.

Embodiment 3

[0041] Precursor synthesis: Mix 1.6g tungsten hexacarbonyl and 10g 2-chlorophenol in a 100ml single-necked flask, heat to 150 under vigorous stirring oC , after reacting for 18 hours, cool the room temperature naturally, add 50ml of 10% ammonia solution and 50ml of petroleum ether successively, wash, extract, and separate liquids. This process is repeated 3 times, and the upper layer is collected. 40 oC Distilled under reduced pressure to obtain 1.8 g of organic tungsten precursor with a yield of about 51.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com