High-damping and high-strength magneto-rheological elastomer and preparation method thereof

A magnetorheological elastomer and high damping technology, which is applied to springs made of plastic materials, mechanical equipment, low internal friction springs, etc., can solve vibration reduction that cannot meet high damping, wide effective damping temperature range and high mechanical strength Need, the effective damping temperature is not wide enough, the mechanical strength is not enough, etc., to achieve the effect of broadening the effective damping temperature range, easy molding, and improving the intrinsic damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The epoxy resin / polyurethane interpenetrating network magnetorheological elastomer involved in the preparation of Example 1

[0021] Raw material preparation: All raw materials were dried in a vacuum oven at 80°C for 2 hours to remove water before use.

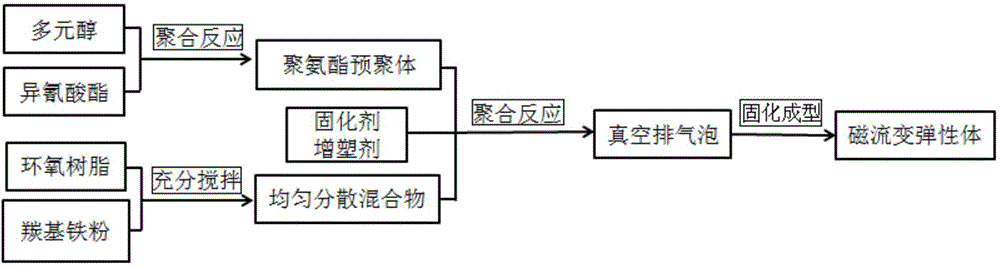

[0022] The preparation method is as follows, and the specific process is shown in figure 1 :

[0023] Step 1, phthalic anhydride diethylene glycol copolymer and 2,6-toluene diisocyanate are mixed and stirred for polymerization reaction to generate polyurethane prepolymer;

[0024] Step 2, 5% brominated epoxy resin by mass, 20% polyurethane prepolymer, 65% carbonyl iron powder, 7% plasticizer, 1% curing agent, 2% reinforcing particles, weighing each component raw materials;

[0025] Step 3, adding carbonyl iron powder and reinforcing granular carbon black into the epoxy resin and fully stirring to form a uniform mixture;

[0026] Step 4, mix and stir the polyurethane prepolymer prepared in step 2 and the mixture in s...

Embodiment 2

[0029] The epoxy resin / polyurethane interpenetrating network magnetorheological elastomer involved in the preparation of Example 2

[0030] Raw material preparation: All raw materials were dried in a vacuum oven at 80°C for 2 hours to remove water before use.

[0031] The preparation method is as follows, and the specific process is shown in figure 1 :

[0032] Step 1, mixing and stirring a mixture of 2,4-diphenylmethane diisocyanate and 4,4-diphenylmethane diisocyanate (each accounting for 50%) and castor oil to generate a polyurethane prepolymer;

[0033] Step 2, by mass ratio bisphenol A type epoxy resin 10%, polyurethane prepolymer 20%, carbonyl iron powder 63%, plasticizer 5%, curing agent is 1%, catalyst 1%, weigh each component raw materials;

[0034] Step 3, adding carbonyl iron powder into the epoxy resin and fully stirring to form a uniform mixture;

[0035] Step 4, mix and stir the polyurethane prepolymer prepared in step 2 and the mixture in step 3 to form an i...

Embodiment 3

[0038] The epoxy resin / polyurethane interpenetrating network magnetorheological elastomer involved in the preparation of Example 3

[0039] Raw material preparation: All raw materials were dried in a vacuum oven at 80°C for 2 hours to remove water before use.

[0040] The preparation method is as follows, and the specific process is shown in figure 1 :

[0041] Step 1, mixing and stirring a mixture of 2,4-diphenylmethane diisocyanate and 4,4-diphenylmethane diisocyanate (each accounting for 50%) and castor oil to generate a polyurethane prepolymer;

[0042] Step 2, by mass ratio novolak epoxy resin 8%, polyurethane prepolymer 16%, carbonyl iron powder 60%, plasticizer 10%, curing agent is 1%, reinforcing particle 5%, weigh each component raw material ;

[0043] Step 3, adding carbonyl iron powder and reinforcing granular graphite into the epoxy resin and fully stirring to form a uniform mixture;

[0044] Step 4, mix and stir the polyurethane prepolymer prepared in step 2 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Damping temperature range | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Damping temperature range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com