Building trough vibration isolator

A technology for vibration isolators and buildings, applied in construction, protection devices, infrastructure engineering, etc., can solve the problems of unfavorable building safety protection, loss of bearing capacity of internal frame structures, and scarce research results, etc., to achieve good protection and load Effect of transfer action, good engineering feasibility, large damping characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

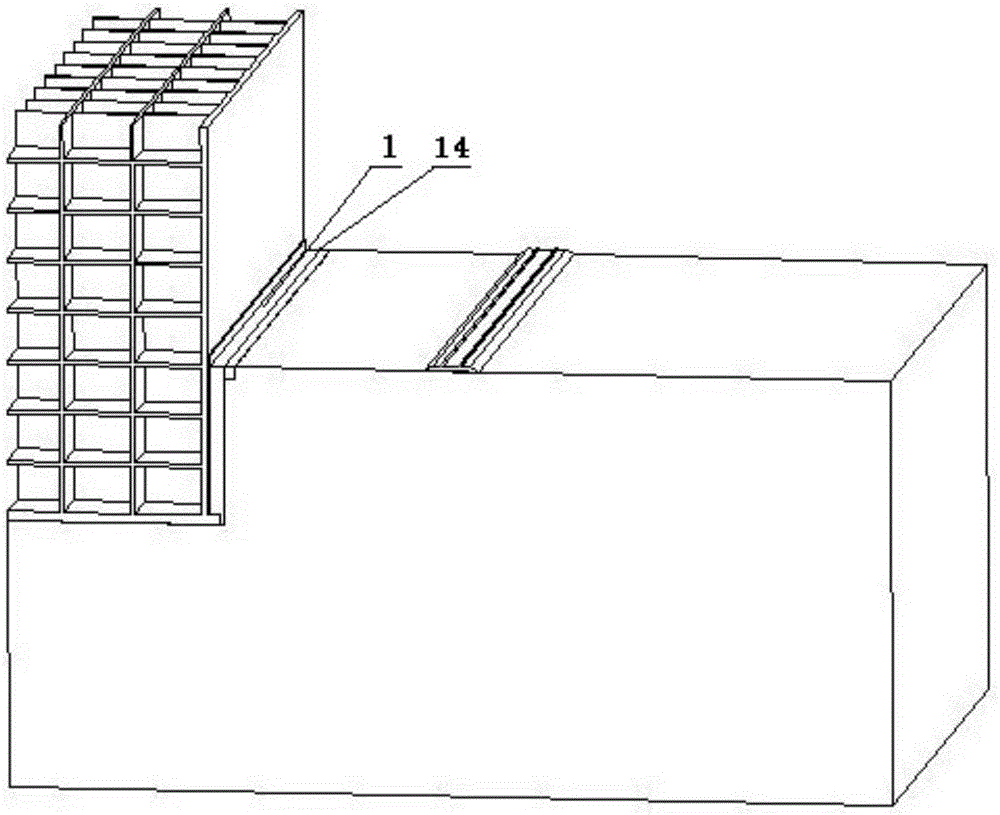

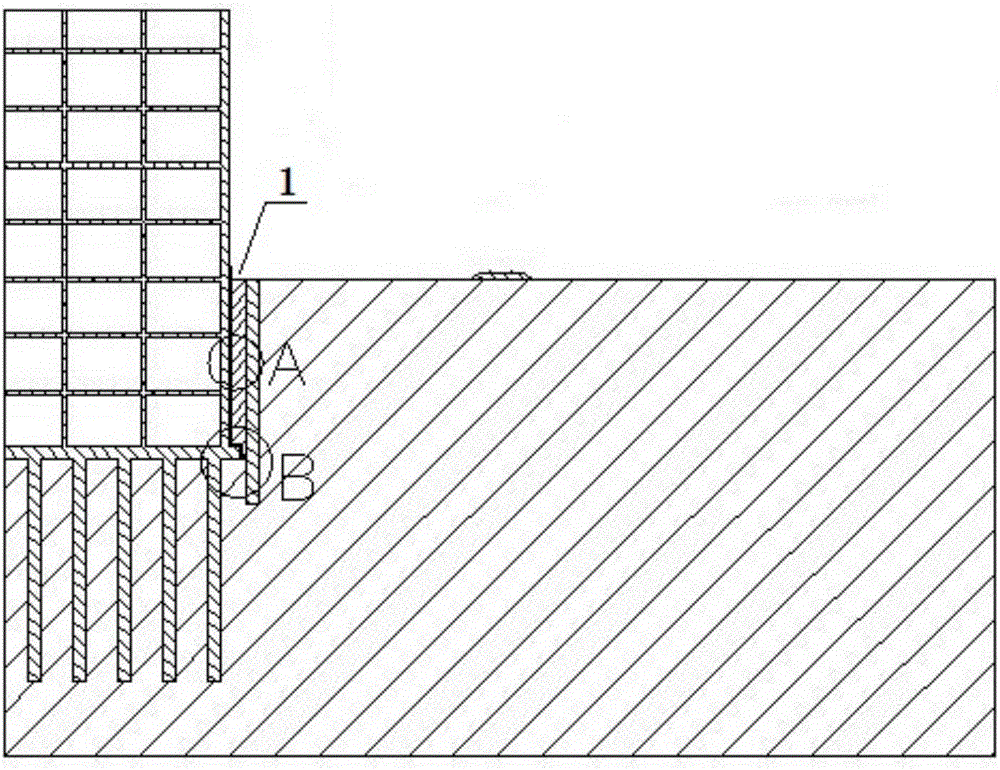

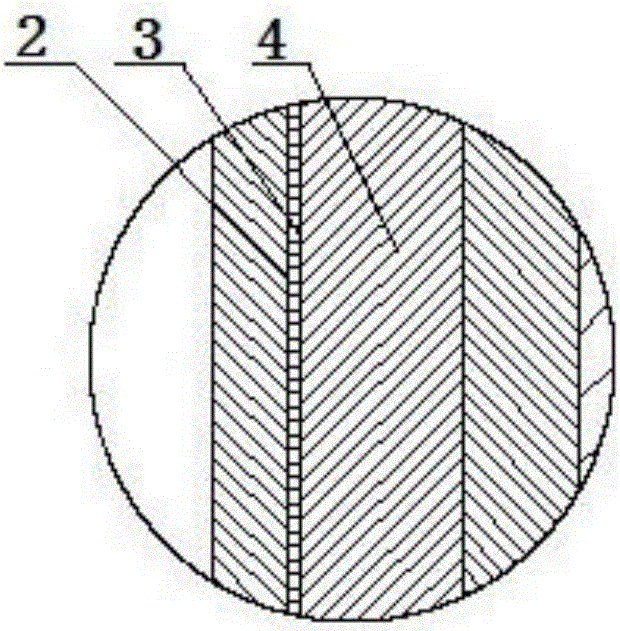

[0040] A building fertilizer tank vibration isolator, the structure is as figure 1 , figure 2 and image 3 As shown, the vibration isolator body 1 is included, and the vibration isolator body 1 is arranged in the fat groove 14 reserved between one side of the building and the side wall of the foundation pit. The vibration isolator body 1 includes a waterproof layer 2, an elastic The damping layer 3, the concrete layer 4 and the rubber backing plate 5, the waterproof layer 2, the elastic damping layer 3, and the concrete layer 4 are successively attached to the fertilizer tank 14, wherein the waterproof layer 2 is attached to the building foundation On the outer wall, the elastic damping layer 3 is closely attached to the waterproof layer 2, the concrete layer 4 is filled between the elastic damping layer 3 and the side wall of the foundation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com