Hot-melting type static electricity conduction removal polymer oil conveying pipe union elbow and preparing method

A technology of elbow joints and polymers, applied in the direction of pipes/pipe joints/fittings, elbows, pipe components, etc., to achieve good engineering adaptability, ensure reliability, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0031] like Figure 1-4 shown.

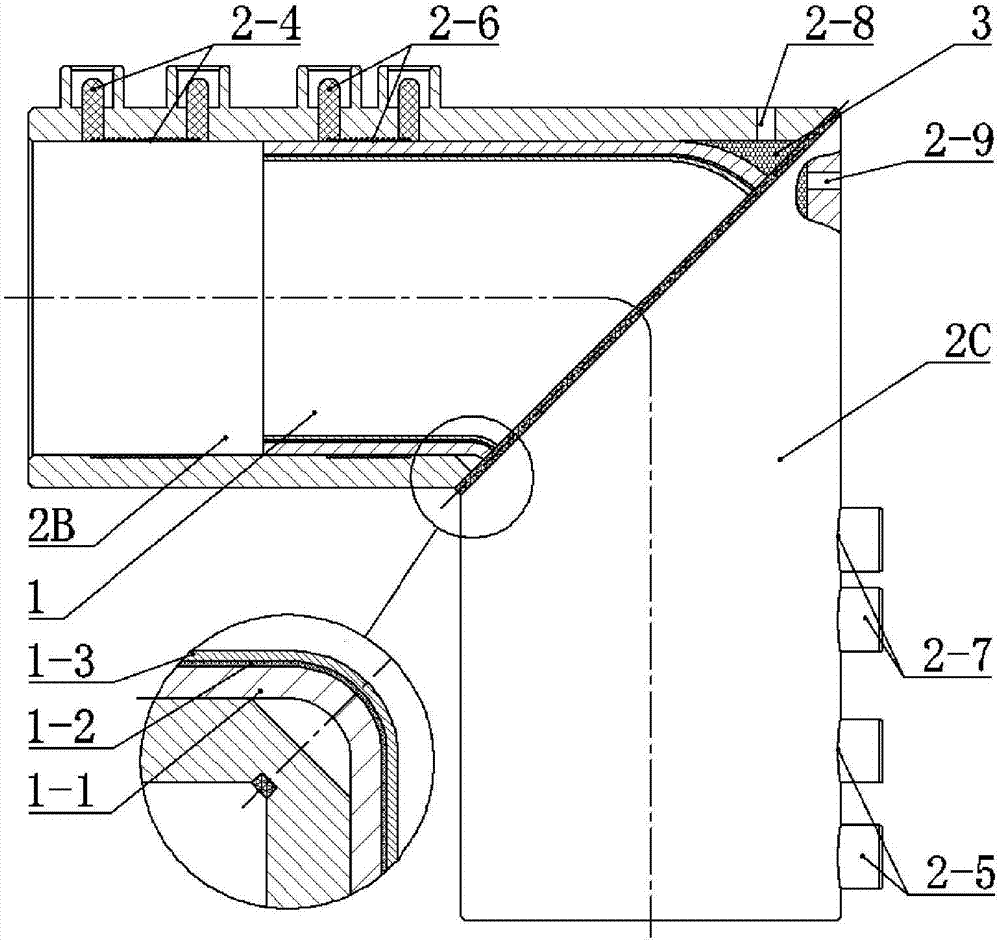

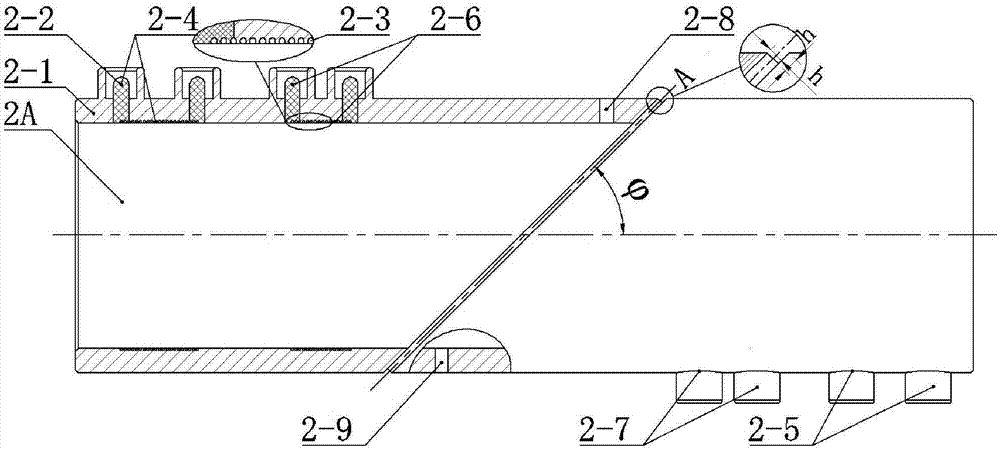

[0032] figure 1 Shown is a 90° hot melt static dissipating polymer fuel line elbow fitting.

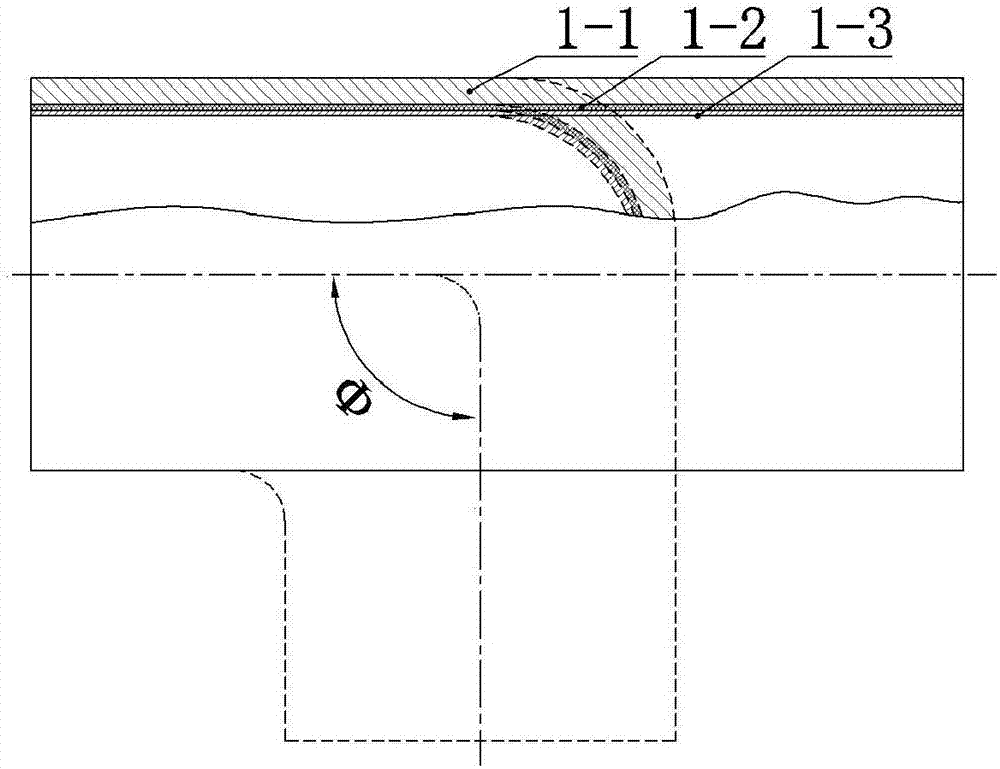

[0033] A hot-melt electrostatically conductive polymer oil pipeline elbow joint, which is composed of an electrostatically conductive polymer oil pipeline elbow 1, a hot-melt polymer outer casing 2 and a filler 3; wherein, the static electricity The elbow 1 of the guide-type polymer oil delivery inner pipe adopts the hot-melt sealing components 2-6, 2-7 arranged on the outer heat-melt polymer sleeve 2 and the outer heat-melt polymer sleeve 2. Hot-melt connection, the filler 3 is injected from the filler injection ports 2-8, 2-9 arranged on the outer casing 2 of the hot-melt polymer, and the filler 3 is preferably an expanded polymer sealant such as polyurethane Foaming agent, which has a porous structure after solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com