A composite material/metal trapezoidal tooth hybrid connection structure and its preparation method

A composite material and hybrid connection technology, which is applied in the field of connection between composite materials and metals, can solve the problems of numerical singularity and insufficient connection strength, and achieve the effects of stress concentration relief, accurate results, and gentle connection shear load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

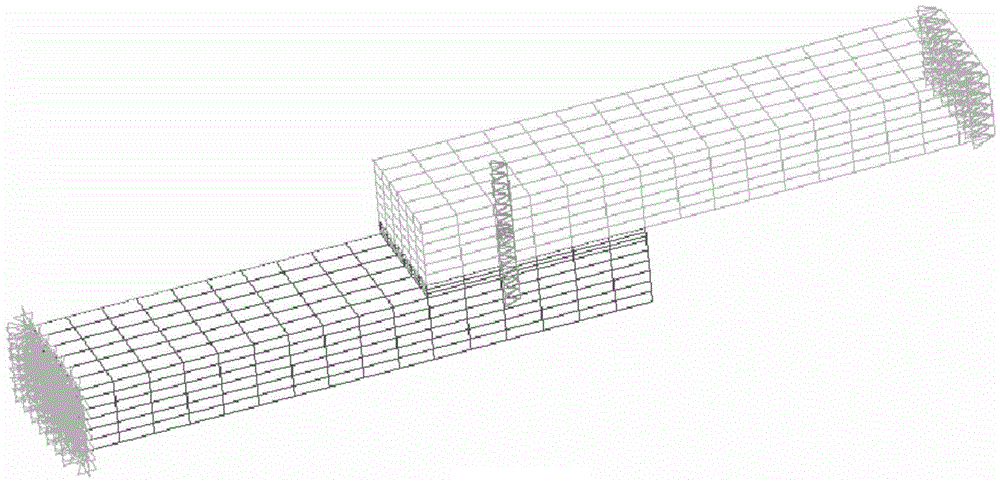

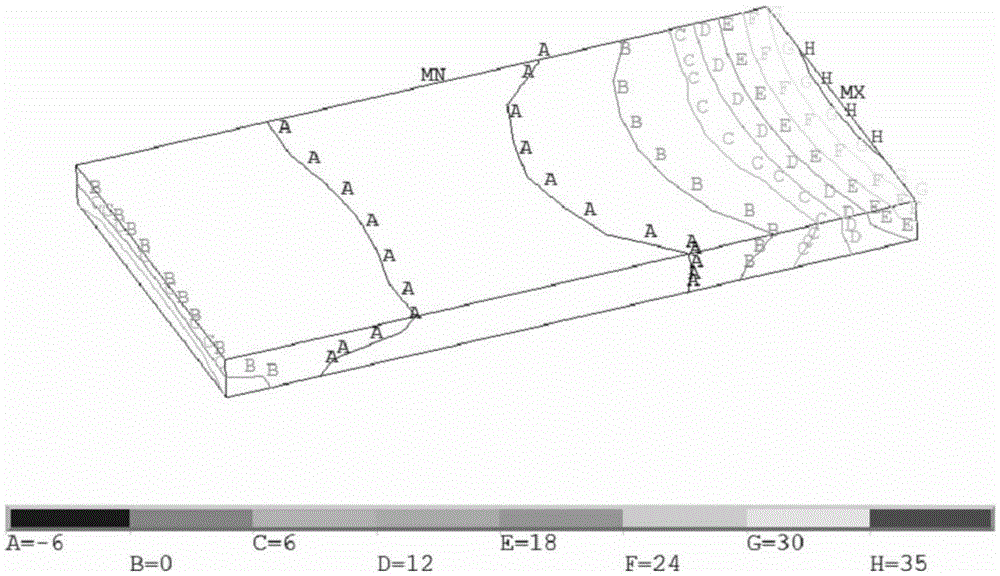

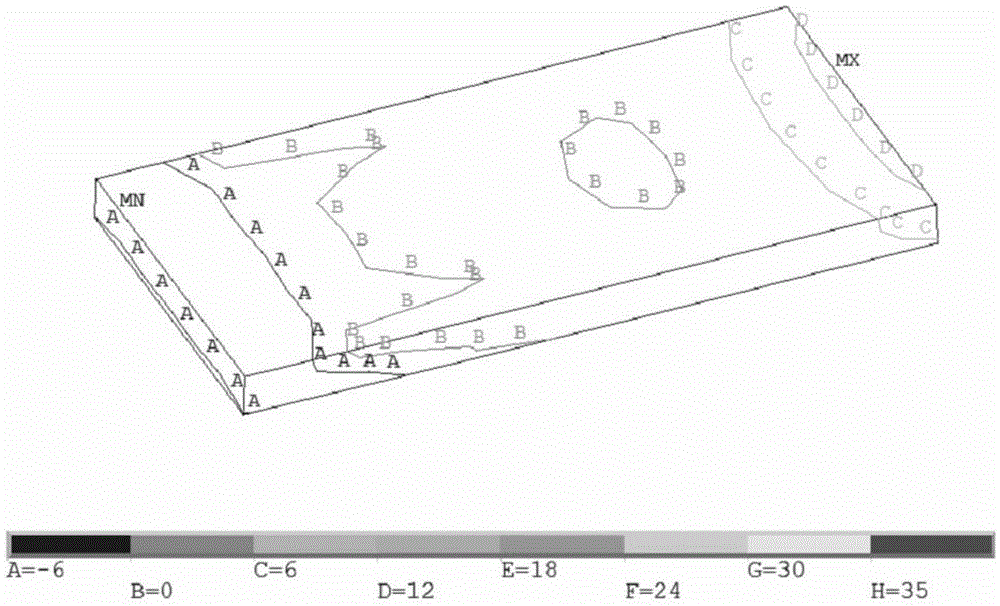

[0052] Such as Figure 7-10 , Shown in 12~13, composite material / metal trapezoidal tooth hybrid connection structure of the present invention, by composite material piece 1, metal piece 2 through bonding agent layer 3 bonding and use bolt fastener in the middle parallel section of trapezoidal tooth 27 are connected as a whole to realize the connection of the composite material part and the metal part.

[0053] Such as Figure 4 As shown, the composite material part 1 is composed of a connecting part 4 and a distal part 5. The connecting part 4 has a glued surface 6, which is connected to the metal part 2 through an adhesive layer 3; the distal part 5 can be terminated on the outer side as required 7 extend outward. The glued surface 6 of the connecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com