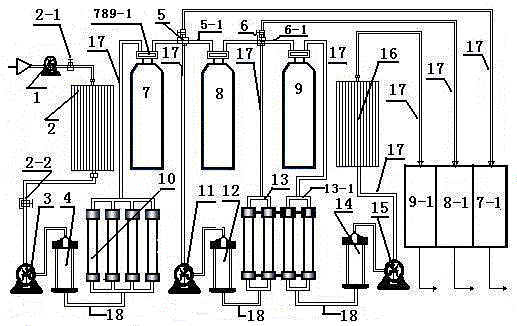

Ganoderan tripeptide filtering system process device

A process device, Ganoderma lucidum polysaccharide technology, applied in peptides, peptide preparation methods, bulk chemical production, etc., can solve problems such as low yield, unsuitable for large-scale application, and large consumption of organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1), a Ganoderma lucidum polysaccharide tripeptide separation and filtration system device process is that the high-pressure pump 3, the pressure generator 4, and the ultra-high pressure reaction tank 7 are arranged in a reinforced explosion-proof installation room (explosion-proof safety requirements), and the high-pressure pump 3, lead out the installation room with a guide pipe 17, link to the stock solution tank 2 in the production workshop, then link and install the supporting facilities cut-off valve 2-1, control valve 2-2, delivery pump 1 on the stock solution tank 2, and then put the The pressure generator 4 leads out of the installation chamber with a return pipe 18, and is connected to one end of the reflux degreasing device 10, and then the other end of the reflux degreasing device 10 is connected to the threaded double-head connector 789- 1 on.

[0021] On the threaded double-head connector 789-1 of the ultra-high pressure reaction tank 7, use a se...

Embodiment 2

[0025] Embodiment two) innovative technology can be processed as follows:

[0026] 1) Send liquid broken Ganoderma lucidum spores into the stock solution tank 2 with the delivery pump 1, enter the process and device of the Ganoderma polysaccharide tripeptide separation and filtration system through the high-pressure pump 3, separate and extract the Ganoderma lucidum polysaccharide peptide, and use the pressure generator 4 to filter the Ganoderma lucidum polysaccharide peptide. Perform ultra-high pressure treatment (hold pressure above 500Mpa for 2 minutes), cut off the polysaccharide peptide chain of Ganoderma lucidum under ultra-high pressure, and the glucose group has three connection methods: glucose (1→), glucose (1→4) and glucose (1→6) , three peptidoglycans can be separated, and at the same time, the polysaccharide peptides can be separated and processed to release other active ingredients, for example: the single component obtained after purification of Ganoderma lucidum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com