A kind of synthetic method of 2-nitrophenylboronic acid

A technology of nitrophenylboronic acid and a synthesis method, which is applied in the field of chemical organic synthesis, can solve the problems of low reaction yield, expensive raw materials, unsuitable for industrial production and the like, achieves high product purity, less isomers, and reduces production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

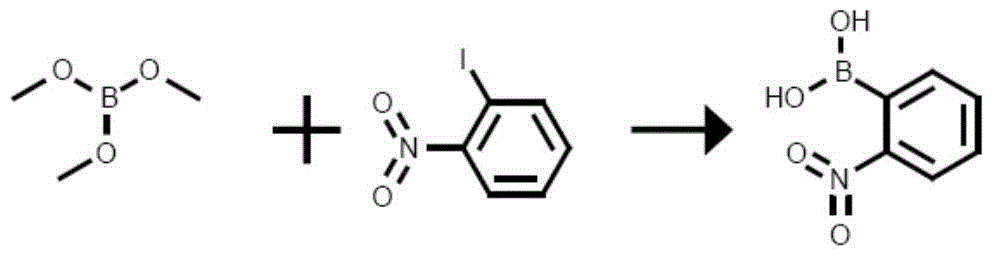

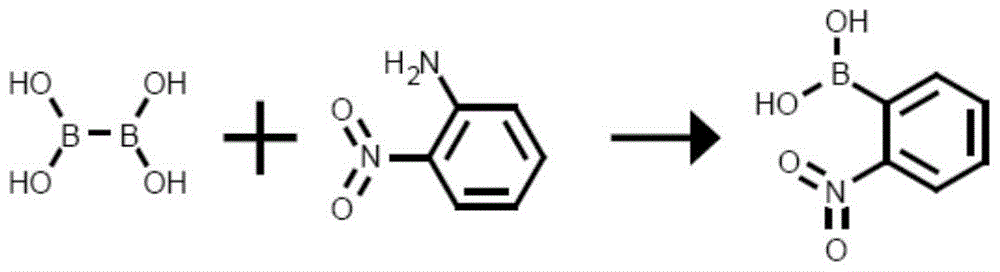

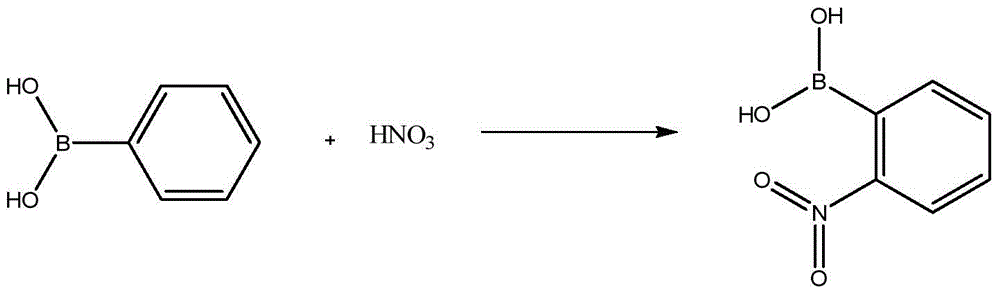

Method used

Image

Examples

Embodiment 1

[0028] Dissolve phenylboronic acid (122g, 1mol) in acetic anhydride (15mol) solution, stir, add nitric acid (126g, 2mol) and ammonium nitrate (1.2g, 0.015mol) dropwise respectively, control the reaction temperature at 0°C, after the reaction is complete Poured into ice water, concentrated to a small volume, cooled, let stand until solid precipitated, filtered, washed with ice water, collected product 164.4g, molar yield 98.4%, HPLC greater than 99.5%.

Embodiment 2

[0030] Mix phenylboronic acid (122g, 1mol) with formic acid acetic anhydride (7mol) in a certain proportion, add nitric acid (189g, 3mol) and potassium nitrate (0.03mol) dropwise respectively, control the reaction temperature to 30 degrees, stir, pour over after the reaction is complete Pour into ice water, concentrate to a small volume, cool, let stand until solid precipitates, filter, wash with ice water, collect 163.8g of product, molar yield 98.1%, HPLC greater than 99.5%.

Embodiment 3

[0032] Mix phenylboronic acid (122g, 1mol) with chloroform (12mol) in a certain proportion, add nitric acid (126g, 2mol) and methyl urea (0.01mol) dropwise respectively, control the reaction temperature at 50 degrees, stir, and pour into Concentrate in ice water to a small volume, cool, let stand until solid precipitates, filter, wash with ice water, collect product 164.8g, molar yield 98.7%, HPLC greater than 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com