System and method for reducing sulfur dioxide emission concentration of sulfur recovery device and desulfurization agent

A sulfur dioxide and sulfur recovery technology, applied in chemical instruments and methods, separation methods, sulfur preparation/purification, etc., can solve the problems of high energy consumption, reduce sulfur dioxide emission concentration of sulfur recovery devices, etc., achieve low investment and save operating costs , the effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

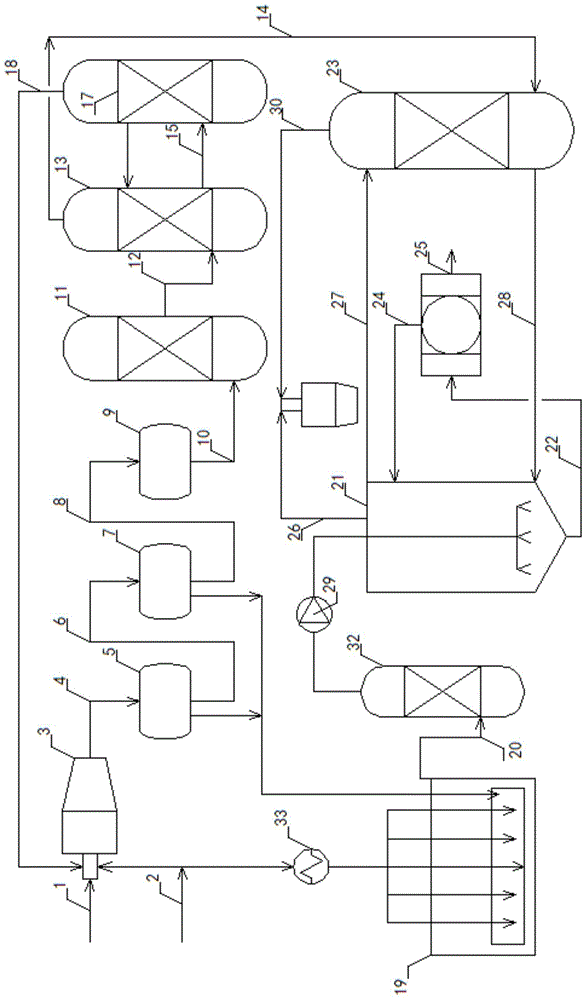

[0049] like figure 1 As shown, the system for reducing the emission concentration of sulfur dioxide from the sulfur recovery unit includes: complex iron desulfurization unit, sulfur recovery unit, and liquid sulfur pool gas stripping unit.

[0050] The sulfur recovery unit includes a reaction furnace 3 , a primary converter 5 , a secondary converter 7 , a hydrogenation reactor 9 , a quenching tower 11 , an amine absorption tower 13 , and an amine absorption regeneration tower 17 connected in sequence. Acid gas 1 and air 2 are sequentially transformed into reactor tail gas 4 , primary reformer tail gas 6 , secondary reformer tail gas 8 , hydrogenation tail gas 10 , quenching tail gas 12 and amine suction tail gas 14 . The amine absorption rich liquid 15 enters the amine absorption regeneration tower 17 .

[0051] The gas stripping device in the liquid sulfur pool includes an air heater 33 , a liquid sulfur pool 19 and a tail gas scrubber 32 connected in sequence. The tail gas...

no. 2 approach

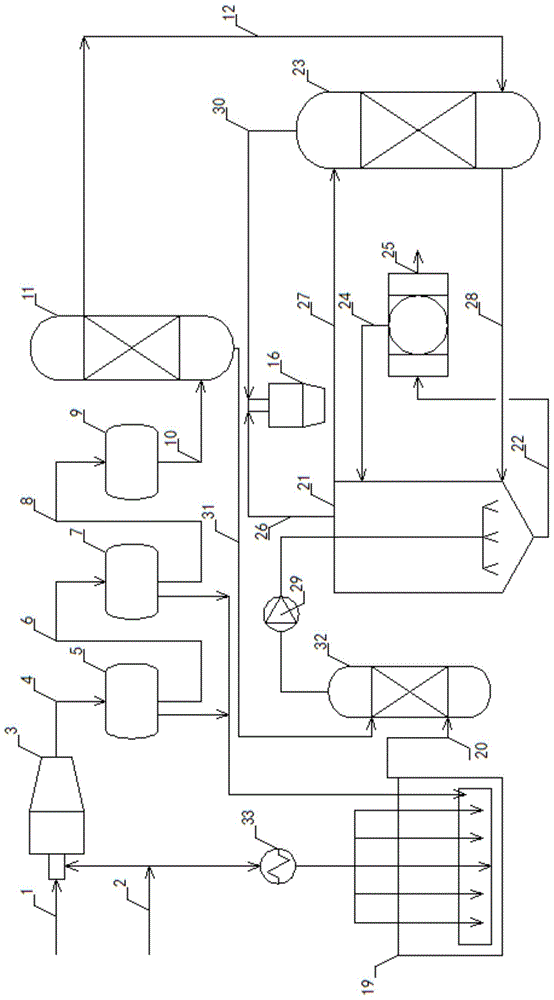

[0055] like figure 2 As shown, the system for reducing the emission concentration of sulfur dioxide from the sulfur recovery unit includes: complex iron desulfurization unit, sulfur recovery unit, and liquid sulfur pool gas stripping unit.

[0056] The sulfur recovery unit includes a reaction furnace 3 , a primary converter 5 , a secondary converter 7 , a hydrogenation reactor 9 and a quench tower 11 connected in sequence. Acid gas 1 and air 2 are transformed into reaction furnace tail gas 4 , primary reformer tail gas 6 , secondary reformer tail gas 8 , hydrogenation tail gas 10 , and quenching tail gas 12 in turn.

[0057] The gas stripping device in the liquid sulfur pool includes an air heater 33 , a liquid sulfur pool 19 and a tail gas scrubber 32 connected in sequence. The tail gas 20 from the liquid sulfur pool stripping enters the liquid sulfur pool stripping tail gas scrubber 32 . Before the liquid sulfur pool 19, an air heating device 33 can be arranged. A booste...

Embodiment 1

[0061] A 40,000-ton / year sulfur recovery unit of a petrochemical company, in figure 1 In the system, the exhaust gas volume at the outlet of quench tower 11 is 12636Nm 3 / h, the hydrogen sulfide content is 2.18%v, the temperature is 70°C, and the pressure is 0.012Mpa. The factory compressed air enters the liquid sulfur pool degassing system 19 after being heated, and the stripping tail gas 20 degassed from the liquid sulfur pool passes through the scrubber 32 with a gas volume of 650Nm 3 / h, the average hydrogen sulfide content is 320ppmv, the temperature is 70°C, and the pressure is increased to 0.035Mpa. Stop the tail gas amine suction system of the original sulfur recovery unit, and enter the exhaust gas 12 of the quenching tower into the absorption tower 23 of the complexed iron desulfurization system. Countercurrent contact in tower 23, purified tail gas 30 goes to incinerator 16. The exhaust gas 20 from the liquid sulfur tank is passed through the water washing tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com