Method for copper smelting by pyrometallurgical process

A technology for pyrometallurgy and blowing furnaces, which is applied in the field of improvement of furnace configuration methods in the pyrometallurgy copper process, and can solve problems such as difficulties in chemical acid production, poor flue gas stability, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

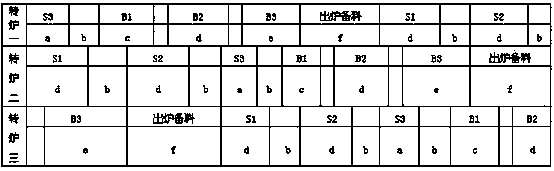

[0008] A method for pyrometallurgical copper smelting. The kiln is configured according to smelting → blowing → refining. The blowing process is equipped with 3 converters, and at least two converters are in the blowing operation state during the blowing process. Main components

[0009] Single-furnace zoning operation system—according to the periodic operation characteristics of the converter, the single-furnace period is divided into six blowing stages, four fixed periods of S1, S2, B1, and B2, and two flexible periods of S3 and B3. The specific blowing time of each interval is determined according to the grade of matte in the smelting furnace, the yield, the specifications of the converting converter, and the oxygen concentration. During the blowing operation, the single-furnace operation of each converter is divided into six stages, and the operation progress of the three converters is in different divisions. The converter for blowing operation is PS blowing furnace.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com