Annular deep and narrow groove turning tool

A turning tool and narrow groove technology, which is applied in the direction of lathe tools, turning equipment, cutting blades, etc., can solve the problems that the size and shape accuracy of the groove cannot meet the technical requirements, and chip removal is difficult, so as to achieve simple structure and easy processing. The effect of low cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

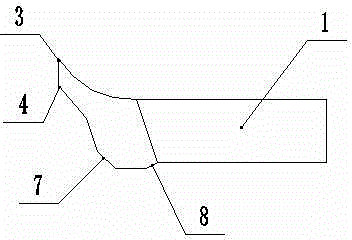

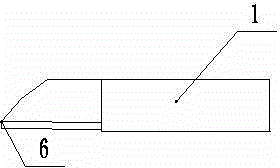

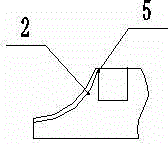

[0016] As shown in the attached figure: a ring-shaped deep and narrow groove turning tool, which is divided into rough turning tool and fine turning tool, wherein both the rough turning tool and the finishing turning tool include: tool handle 1, cutter head arc 2, cutter head front Angle 3, cutter head rear angle 4, cutter head auxiliary rear angle 5, cutter head auxiliary deflection angle 6, front chamfer 7, rear chamfer 8, tool handle 1 is set on the left side of the turning tool, and tool head arc 2 is set on At the front of the turning tool, the rake angle 3 of the tool head is located at the tip of the arc 2 of the tool head; , the cutter head secondary angle 6 is located below the cutter head back angle 4, the front chamfer is set at the front end below the cutter head arc, the rear chamfer is set at the rear end of the front chamfer cutter head arc 2, and the cutter head rake angle 3. The cutter head rear angle 4, the cutter head auxiliary relief angle 5, the cutter hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com