Kitchen and kitchen waste treatment process and its treatment system

A kitchen waste and treatment process technology, applied in the direction of solid waste removal, etc., can solve the problems of low cost, complicated treatment process, and inability to be widely used, and achieve high resource reuse rate, simple system structure, The effect of small equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

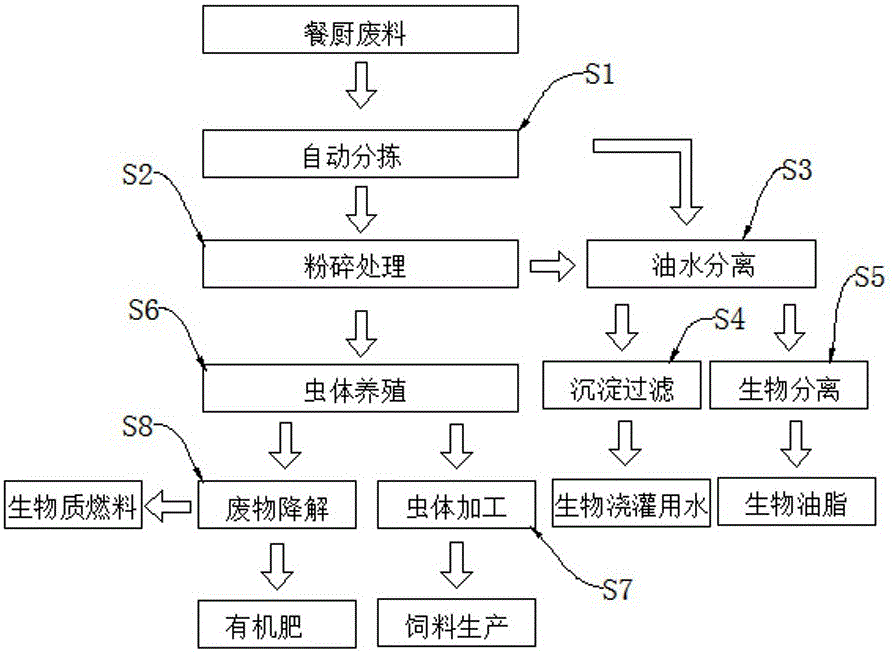

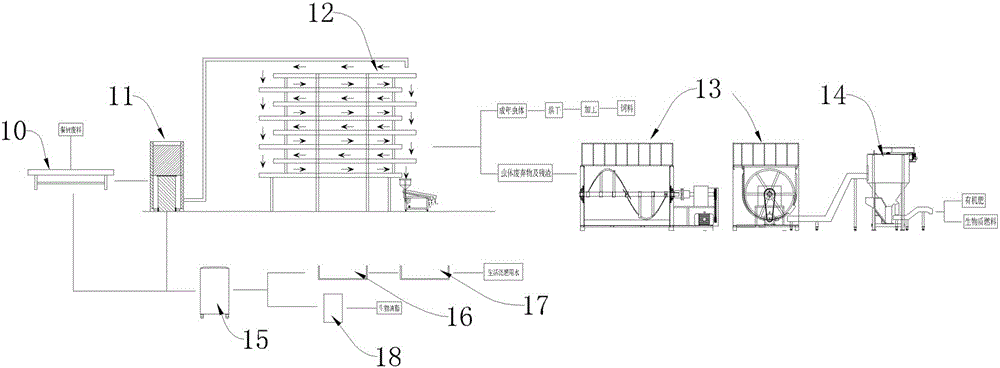

[0042] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0043] refer to figure 1 , a kind of kitchen waste treatment process of the present invention, comprises the following steps:

[0044] S1: Automatic sorting, transfer the mixture of kitchen and kitchen waste to the automatic sorting platform for preliminary solid-liquid separation of waste;

[0045] S2: Pulverization treatment, the solid-phase waste passed through the automatic sorting platform is put into the pretreatment pulverizer 11 for pulverization;

[0046] S3: oil-water separation, the liquid phase mixture on the automatic sorting platform and the oil-water mixture separated by the pulverizer enter the oil-water separation equipment 15 for oil-water separation;

[0047] S4: sedimentation filtration: the water phase separated from the oil-water separation equipment 15 enters the first-stage sedimentation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com