Method and device for realizing wastewater zero discharging based on multiple-effect sound wave action

A zero-discharge, waste-water technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as increasing investment costs, inability to continuously operate equipment systems, and large footprint, and achieves a solution to the problem. The effect of fouling and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

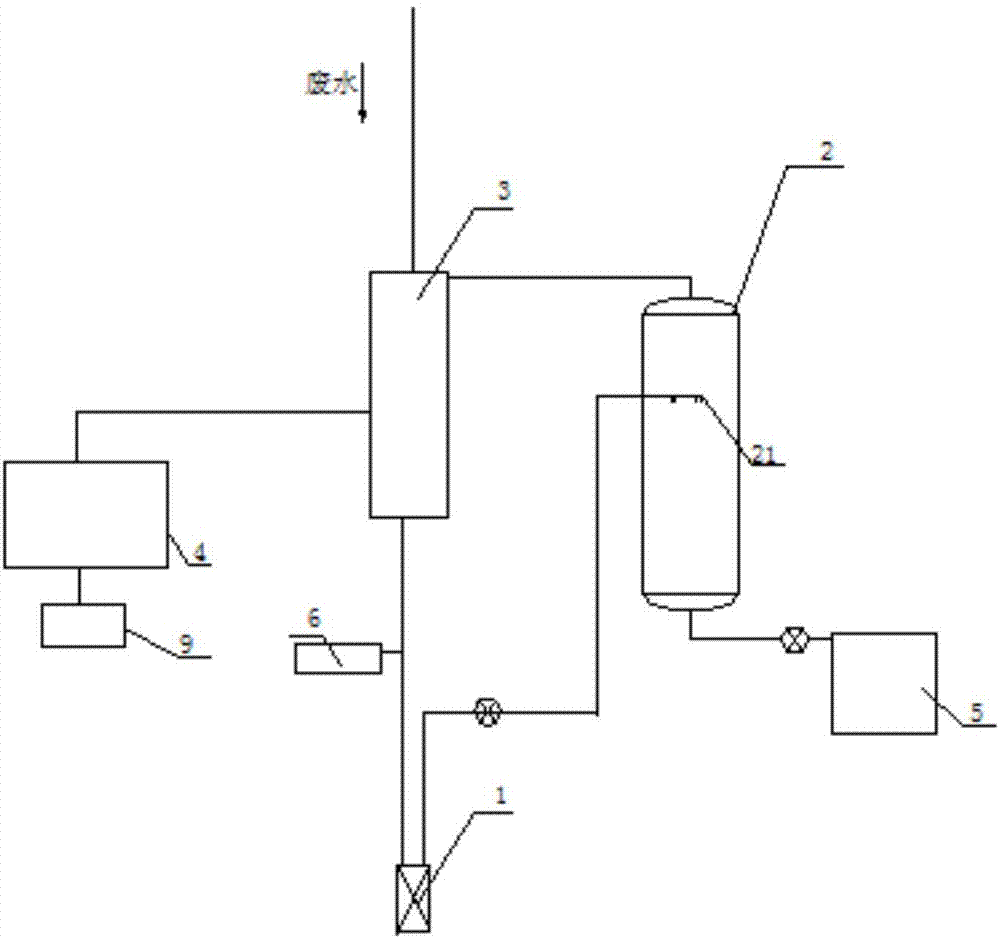

Embodiment 1

[0064] This example provides a method for realizing zero discharge of wastewater based on multi-effect acoustic wave action. The desulfurization wastewater is evaporated at low pressure in the form of atomization, and the water vapor generated after low-pressure evaporation is recovered after heat exchange and condensation. The completely evaporated wastewater is evaporated again, and the low-temperature evaporation can include more than one low-pressure evaporator set in parallel or more than one low-pressure evaporator set in series in the actual application process. The evaporated waste water is heated and then sprayed into the low-pressure evaporator for cyclic evaporation; the high-temperature steam generated by the evaporation of the previous low-pressure evaporator in the series of low-pressure evaporators is used as the heat source of the subsequent low-pressure evaporator, and the previous low-pressure evaporation The unevaporated waste water is sent to the subsequent ...

Embodiment 2

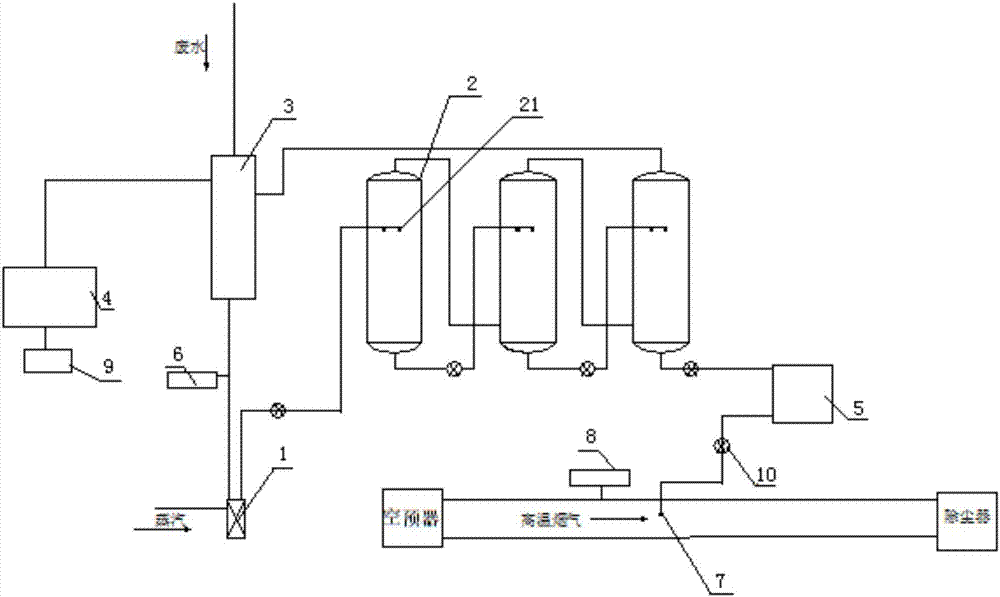

[0068] This embodiment is a further improvement on the basis of Embodiment 1, wherein the number of low-pressure evaporators is more than one, connected in series, and the water outlet of the previous low-pressure evaporator is connected to the high-pressure nozzle of the next low-pressure evaporator through a pipeline. The gas outlet of the former low-pressure evaporator is connected with the inlet of the latter low-pressure evaporator. The interior of the pipe wall of the waste water preheater 3 and the waste water heater 1 is connected with the hydroacoustic transducer 6 used for descaling inside the pipe wall through pipelines, and the waste water preheater 3 is produced by the last stage of low-pressure evaporator The cooling heat exchanger for the evaporated gas realizes the circulation heat exchange of the evaporated gas and waste water through the transfer pump 10. The evaporated gas is cooled to precipitate condensed water and the waste water is heated up at the same t...

Embodiment 3

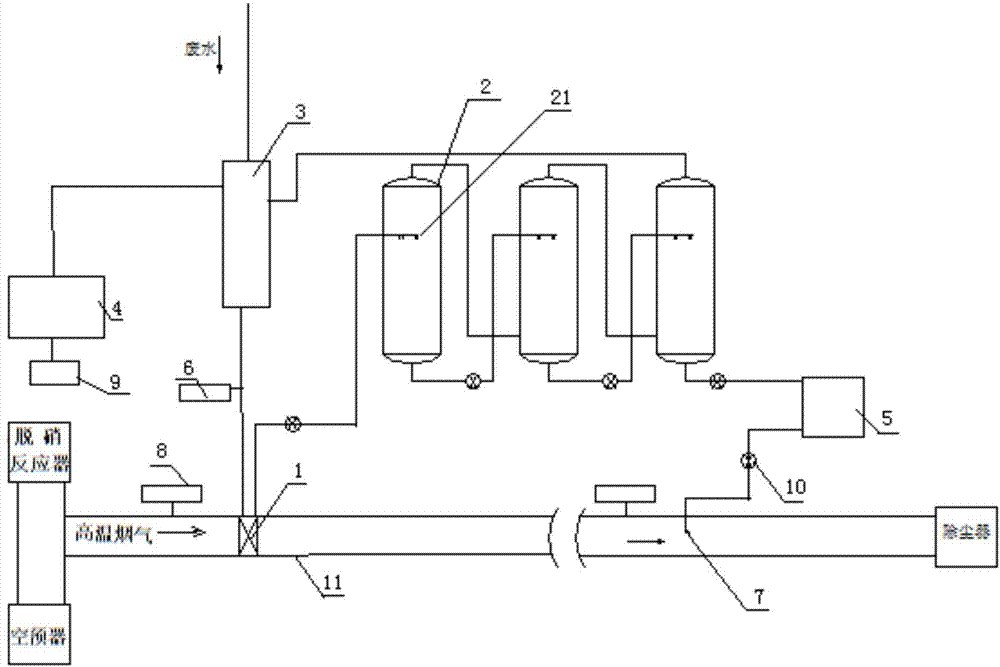

[0070] This example is the specific application of the device provided in Example 2 to realize the zero discharge of wastewater based on the action of multi-effect sound waves in the treatment of desulfurization wastewater in power plants, such as figure 2 As shown, the high-temperature flue gas in the high-temperature flue gas pipeline is used as the heat source of the wastewater heater 1, and a side branch pipeline 11 is set in the pipeline between the denitrification reactor and the air preheater of the power plant system before the dust collector, and the wastewater is heated The device 1 is arranged in the bypass pipeline 11, and the exhaust pipe of the waste water heater 1 is provided with a pneumatic generator 8 for removing dust outside the exhaust pipe. The frequency range of the pneumatic generator 8 is 20Hz-10kHz, and the sound pressure level is greater than 160dB; The wastewater outlet of the concentrated water treatment tank 5 is connected to a high-sound intensit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com