Three-layer composite membrane of sodium alginate, polydopamine-polyethyleneimine and polyacrylonitrile, and preparation and application of three-layer composite membrane

A polyethyleneimine and polyacrylonitrile technology, applied in the field of membrane separation, can solve problems such as poor interface adhesion, and achieve the effects of improved interface force, easy operation and high selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1. Preparation of sodium alginate / polydopamine-polyethyleneimine / polyacrylonitrile three-layer composite film.

[0019] Step 1. Soak the polyacrylonitrile ultrafiltration membrane in absolute ethanol solution for more than 1 hour to pre-wet;

[0020] Step 2. At room temperature, add 0.605 g of tris to 100 ml of deionized water to prepare a solution with a concentration of 50 mM, adjust the pH to 8.5 with 1M hydrochloric acid solution; add 0.1 g of polyethyleneimine and 0.2 g dopamine, stirred for 2 min at room temperature at 300 rpm to dissolve.

[0021] Step 3: Fix the polyacrylonitrile ultrafiltration membrane pre-wetted in step 1 in the container, so as to ensure that only the front side of the membrane (that is, the side without non-woven fabric) contacts the solution. Pour the solution obtained in step 2 into a container, and then put it into a constant temperature shaker at 25°C to react for 4 hours; pour out the reacted solution, wash the surface of the ...

Embodiment 2

[0024] Example 2. Preparation of sodium alginate / polydopamine-polyethyleneimine / polyacrylonitrile three-layer composite film.

[0025] Step 1, with embodiment 1;

[0026] Step 2, basically the same as in Example 1, except that the amount of polyethyleneimine added to the tris solution is changed from 0.1g to 0.2g;

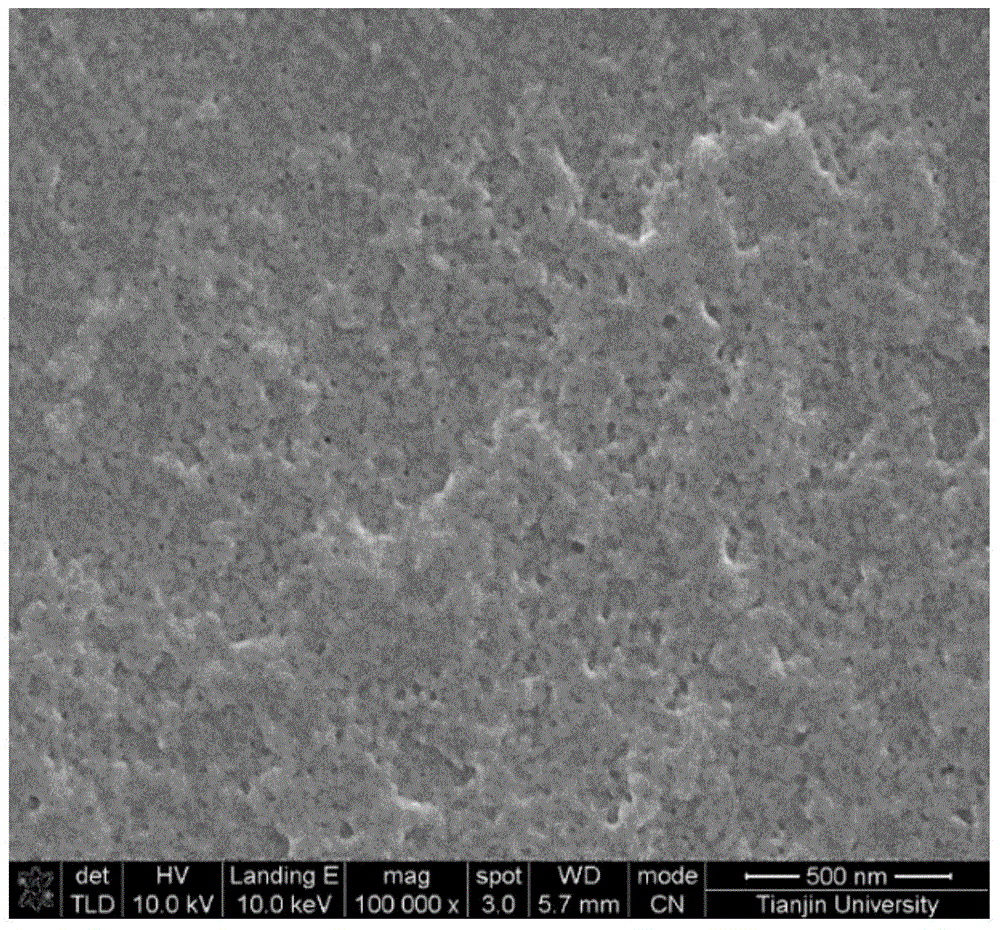

[0027] Step 3, with embodiment 1, the SEM surface figure of the obtained polydopamine-polyethyleneimine / polyacrylonitrile two-layer film is as follows figure 1 shown;

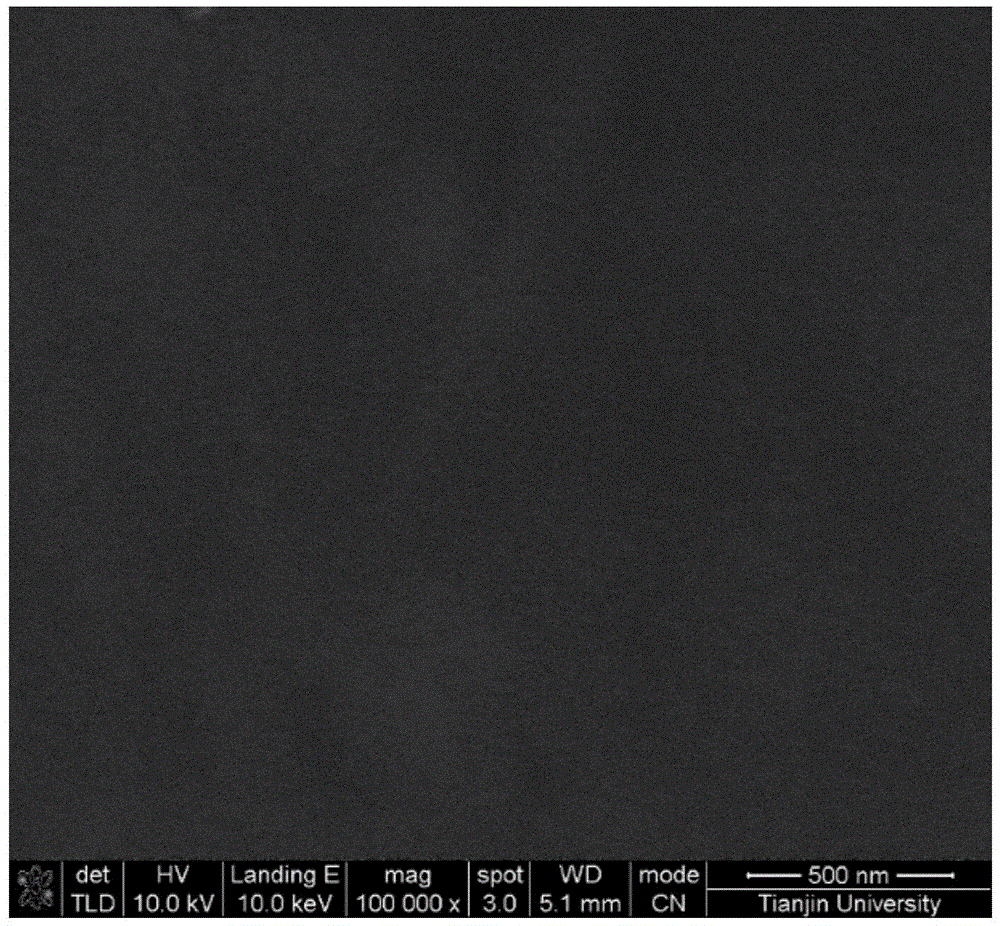

[0028] Step 4, the same as in Example 1, the SEM surface diagram of the finally obtained sodium alginate / polydopamine-polyethyleneimine / polyacrylonitrile three-layer composite film is as follows figure 2 Shown, wherein, the mass ratio of polyethyleneimine and polydopamine is 1.35.

[0029] Compared figure 1 and figure 2 It can be seen that the surface of the two-layer film is rough and has nanopores, while the surface of the three-layer film is dense and smooth, which proves that the sodium a...

Embodiment 3

[0031] Example 3. Preparation of sodium alginate / polydopamine-polyethyleneimine / polyacrylonitrile three-layer composite film.

[0032]Step 1, with embodiment 1;

[0033] Step 2, basically the same as in Example 1, except that the amount of polyethyleneimine added to the tris solution is changed from 0.1g to 0.4g;

[0034] Step 3, with embodiment 1;

[0035] Step 4, the same as in Example 1, finally obtained sodium alginate / polydopamine-polyethyleneimine / polyacrylonitrile three-layer composite film, wherein the mass ratio of polyethyleneimine to polydopamine is 0.6.

[0036] The sodium alginate / polydopamine-polyethyleneimine / polyacrylonitrile three-layer composite membrane prepared in Example 3 was used to test the ethanol / water separation performance. The ethanol / water separation performance test was carried out at 76°C and the mass ratio of ethanol / water in the raw material solution was 9:1, and the permeation flux was 1464g / m 2 h, the separation factor is 394.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com