Combined wet-type pipeline dedusting device

A technology of dust removal device and pipeline, which is applied in the direction of combination device, dispersed particle separation, chemical instrument and method, etc., can solve the problems of dust removal equipment due to small driving section area, dust can not be removed, can not meet performance requirements, etc., and can reduce coal consumption. Probability of dust explosion, simple use and maintenance, low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

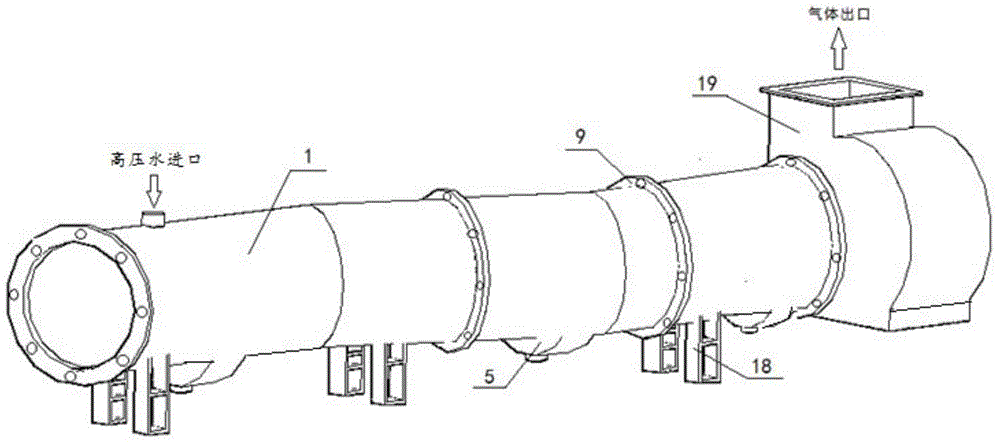

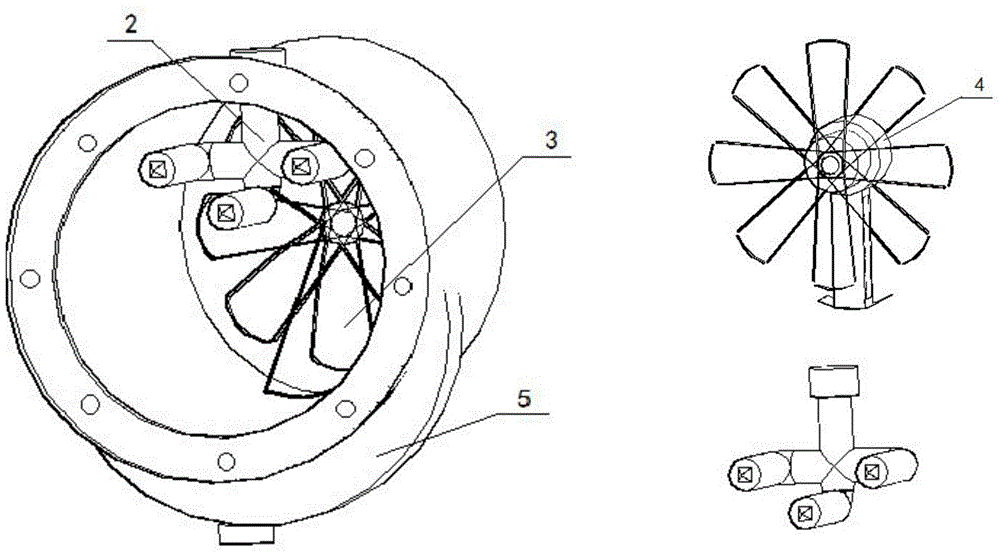

[0018] A combined wet pipeline dust removal device, including 1. Dust removal air cylinder, 2. High-pressure water mist nozzle, 3. Fan blade, 4. Motor, 5. Sewage channel, 6. Inclined pipe, 7. Fixed rod, 8. Spiral type Rotary piece, 9. bolt flange structure, 10. connecting tripod, 11. fixed ring, 12. fixing tripod, 13. bearing, 14. connecting shaft. 15. Fixed shaft, 16. Filter cartridge, 17. Implementation of dust collector, 18. Fixed bracket, 19. Fan, primary dust removal air cylinder 1 (A) is equipped with high-pressure water mist nozzle 2 on the outer wall, and fan blades on the inner wall 3 and motor 4, and the bottom of the inner wall is provided with a sewage channel 5 (A), wherein the fan blade 3 is connected to the motor 4, and the motor 4 is fixed on the inner wall of the dust removal air cylinder 1 (A); the secondary dust removal system includes the dust removal air cylinder 1 (B), the dust removal air cylinder 1 (B) is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com