Functional medical dressing containing chitosan and hydrocolloid

A technology of hydrocolloid and chitosan, applied in medical science, absorbent pads, bandages, etc., can solve the problems of unsatisfactory hemostatic effect, poor healing ability, easy to fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

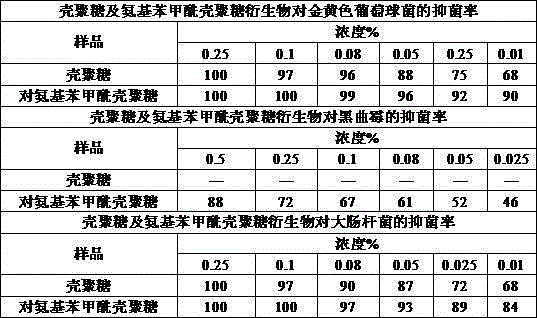

[0041]Example 1: Put p-aminobenzoic acid into a three-necked bottle, add anhydrous ether, dissolve, then add a slight excess of thionyl chloride, put it in an ultrasonic cleaner, oscillate ultrasonically for 10 minutes, continue the reflux reaction and cool to room temperature After the reaction is completed, distill under reduced pressure until no liquid is evaporated, and after recrystallization, p-aminobenzoyl chloride is obtained. Add a certain amount of chitosan acetic acid solution with a concentration of 1% to the three-necked bottle, and then add p-aminobenzoyl chloride (the ratio of chitosan acetic acid solution to p-aminobenzoyl chloride is 3:1), The reaction was shaken and allowed to stand overnight. After the reaction is completed, add a large amount of acetone to precipitate the product, filter it with suction, soak it in a mixed solvent of absolute ethanol and anhydrous ether for 24 hours, then filter it with suction, and extract the filter cake with acetone for ...

Embodiment 2

[0042] Embodiment 2: formula is 16 weight parts SIS, 8 weight parts PIB1, 4 weight parts PIB2, 4 weight parts LIR-50, 10 weight parts guar gum, 14 weight parts CMC, 10 weight parts X-CMC, 5 weight parts Parts of chitosan, 15 parts by weight of rosin resin, 13 parts by weight of naphthenic oil, 1 part by weight of 1010.

Embodiment 3

[0043] Embodiment 3: formula is 18 weight parts SIS, 8 weight parts PIB1, 4 weight parts PIB2, 4 weight parts LIR-50, 10 weight parts guar gum, 14 weight parts CMC, 10 weight parts X-CMC, 5 weight parts Parts of aminobenzoyl chitosan derivatives, 15 parts by weight of rosin resin, 13 parts by weight of naphthenic oil, 1 part by weight of 1010.

[0044] Weigh various raw materials according to the formula described in Example 2 and Example 3, add rubber, tackifying resin, additives and other raw materials into the internal mixer, and vacuumize at a temperature of 135°C-160°C Mix for 20-30 minutes, when the temperature drops to 80°C-100°C, add neutral colloids, polyanion colloids, and polycation colloids, vacuumize and mix for 30-45 minutes, and then discharge, at a temperature of 70°C-90°C Next, use a vulcanizing machine to mold it into a sheet with a thickness of 1mm. One side is attached with a release paper or a release film, and the other side can be attached with a PU brea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com